Alright: I decided to brew again today. It's only 40*, I have a free evening, so here we are. I'm gonna run through basically everything I'm going to do and see if the friendly residents of HBT (thanks for all your help already!) have any recommendations.

Recipe: (mostly) SMaSH

12.5# Vienna

Hops:

1 oz Columbus @ 60

.5 oz Mosaic @ 30

.5 oz Mosaic @ 10

1 oz Mosaic @ 5

No whirlpool or dry hops - don't feel like dealing with it.

I'm going to use White Labs SF Lager Yeast and ferment it slightly warmer, at ale temps. I'm going out of town on Friday for 4-5 days, so my plan is to use my keezer as a ferm chamber - once I brew it tonight and pitch the yeast, I'm going to set the temp to 53 and let it ferment there until I come home, where I'll probably keep it cool as I can in a swamp cooler for a few days before letting it warm up.

One of my favorite beers was made with fermenting SF lager yeast warm, so I'm hoping this comes out well. I don't have time to make a starter, unfortunately. I changed my efficiency to 65% in BS, and I'm hitting 1.055 OG iirc (not home to check).

I set my kettle losses for 0, to just test my mash efficiency, and fermenter losses for 0.75 gallons. Priceless and BS both have my mash volume at 8 gallons of water.

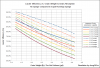

Bru'n water, done for my grain bill with a Lovibond of 3.5, has my initial pH at 5.72. Here's a picture of the sheet with the adjustments I've decided on so far:

http://imgur.com/a/b6DbP

I set my Beersmith efficiency to 65% - a little lower than I'd like, but I seem to be 60 or under consistently, so we'll start there. I'm going to ask the LHBS to set the gap as tight as they can, and double mill if possible.

I don't want a ton of sweetness, so I'm going to try and mash a bit lower - 150 probably. On the other hand it's still cold and I still lose heat, so I'm probably going to aim to mash in to around 152 so that I stay within conversion range. I might try wrapping an extra comforter around my kettle during the mash. My plan is a 75 minute mash this time - 60 minutes of mashing, then turning my burner on very low to give a small mashout step.

Anything I'm missing? Any other simple improvements I can make?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)