Stop overthinking this. Chill as far as you can with your ground water then put it in your fermentation chamber to cool to your fermentation temperature then pitch the yeast.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fast solution for using IC pre-chiller for 5 gallons lager?

- Thread starter user 246304

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 3, 2020

- Messages

- 3,256

- Reaction score

- 3,956

Early on in my brewing journey I only had an immersion chiller. I held that view that the yeast needed to be pitched right away. I would get it as low as I could, pitch the yeast, then stick in the fermentaton chamber. Then I started to ease off that view by chilling to let the wort reach the high end of the lager temperature, then pitched the yeast. Along the way, I started using a plate chiller and when I started whirlpooling hops, I realized I could recirculate the wort to get it down in temperature a little lower than a single pass through would. This also works with a counterflow chiller, which I now use instead of the plate chiller. Another change I have made is that I now try to pitch at under the intended set point for the lager by a few degrees, so I let the wort get to that temperature in the ferm chamber, then pitch. I've read a number of anecdotes of brewers not having issues with allowing wort to cool overnight. I've been pretty successful all around with each of these methods, in general, it's the overall temperature control during the entire fermentation that is the most important in my view as far as temperature effects. I've always use liquid yeasts as well.Newbie with no lager experience, but is this really a big deal? Nobody just chills to tap water temp, then places in the chamber to reach pitch temperature (say, overnight)?

I've never added in the IC to my PC or CFC because the ice maker on my POS Samsung fridge broke and I just don't ever have the time on brew day to run out and get ice and would typically not remember to get it beforehand. Freezer is generally full as well.

Newbie with no lager experience, but is this really a big deal? Nobody just chills to tap water temp, then places in the chamber to reach pitch temperature (say, overnight)?

Besides giving bacteria and wild yeast a chance at taking a foothold, there is also an oxidation risk. The wort is now in a temperature zone where it can start holding on to oxygen it was exposed to during the transfer into the fermenter. Usually it's not a problem because an immediate pitch of yeast will scavenge the oxygen. I would risk pitching yeast a few degrees warm before I'd let it sit for 12 hours, but there are a lot of factors like how the wort got transferred and how well the fermenter seals (cooling wort creates a vacuum in the fermenter). If you could flood it with CO2 and leave some pressure in there, that would be fine.

I do it with all my beers, lagers and ales. With zero issues. Put the lid on your fermenter, you don’t have to seal it, while it cools then pitch your yeast when it reaches your fermentation temperature.Newbie with no lager experience, but is this really a big deal? Nobody just chills to tap water temp, then places in the chamber to reach pitch temperature (say, overnight)?

user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

Always reluctant to go with a plate chiller, but our shop has a used one at $79. Bit leery as they can't be broken down to be cleaned, but thought a CIP with caustic might be sufficient. Most likely, if I end up with at least one pump on the system, I'll go CFC. In the meantime, the pond pump/recirc setup is awesome. Thanks again guys.

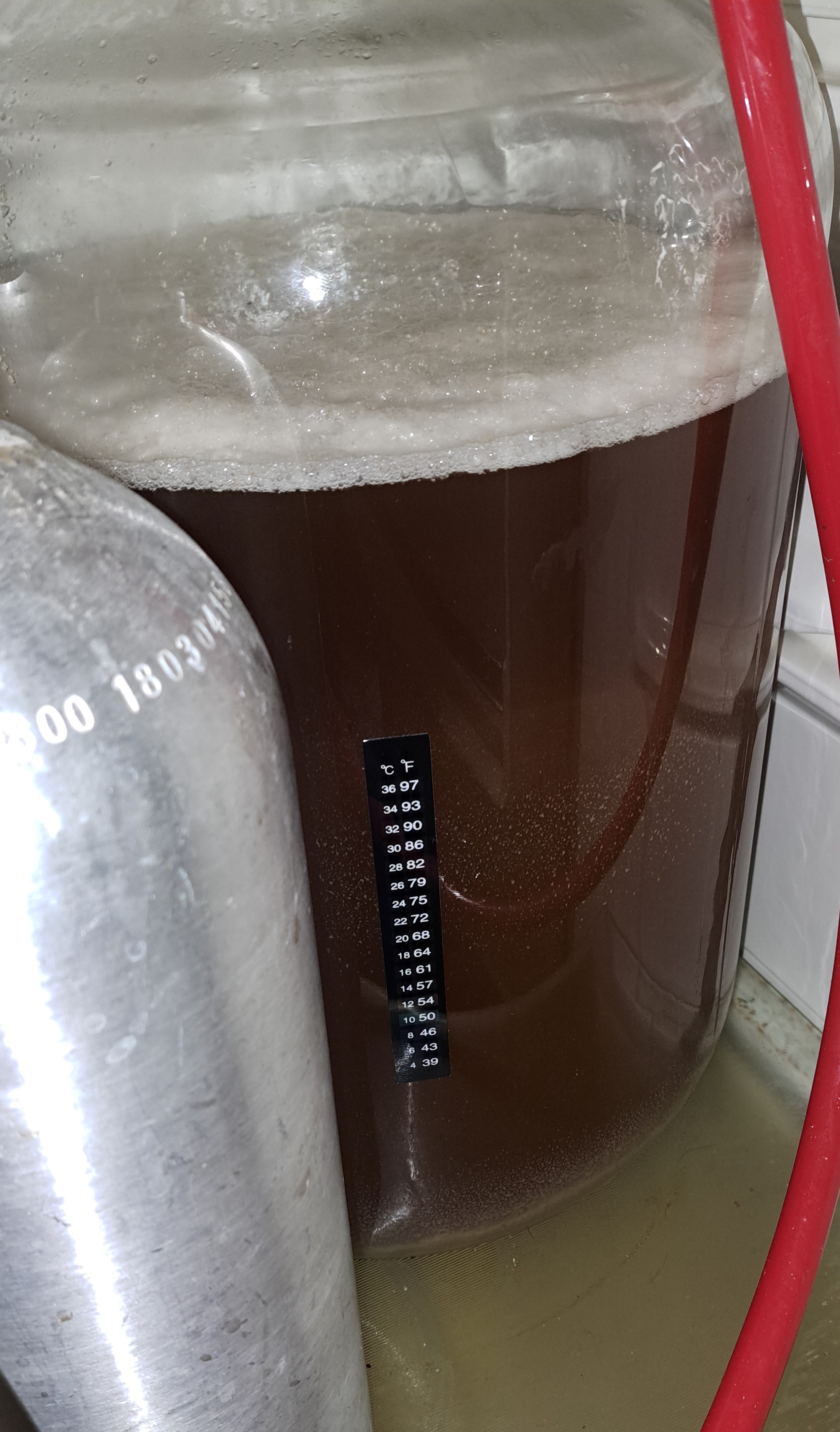

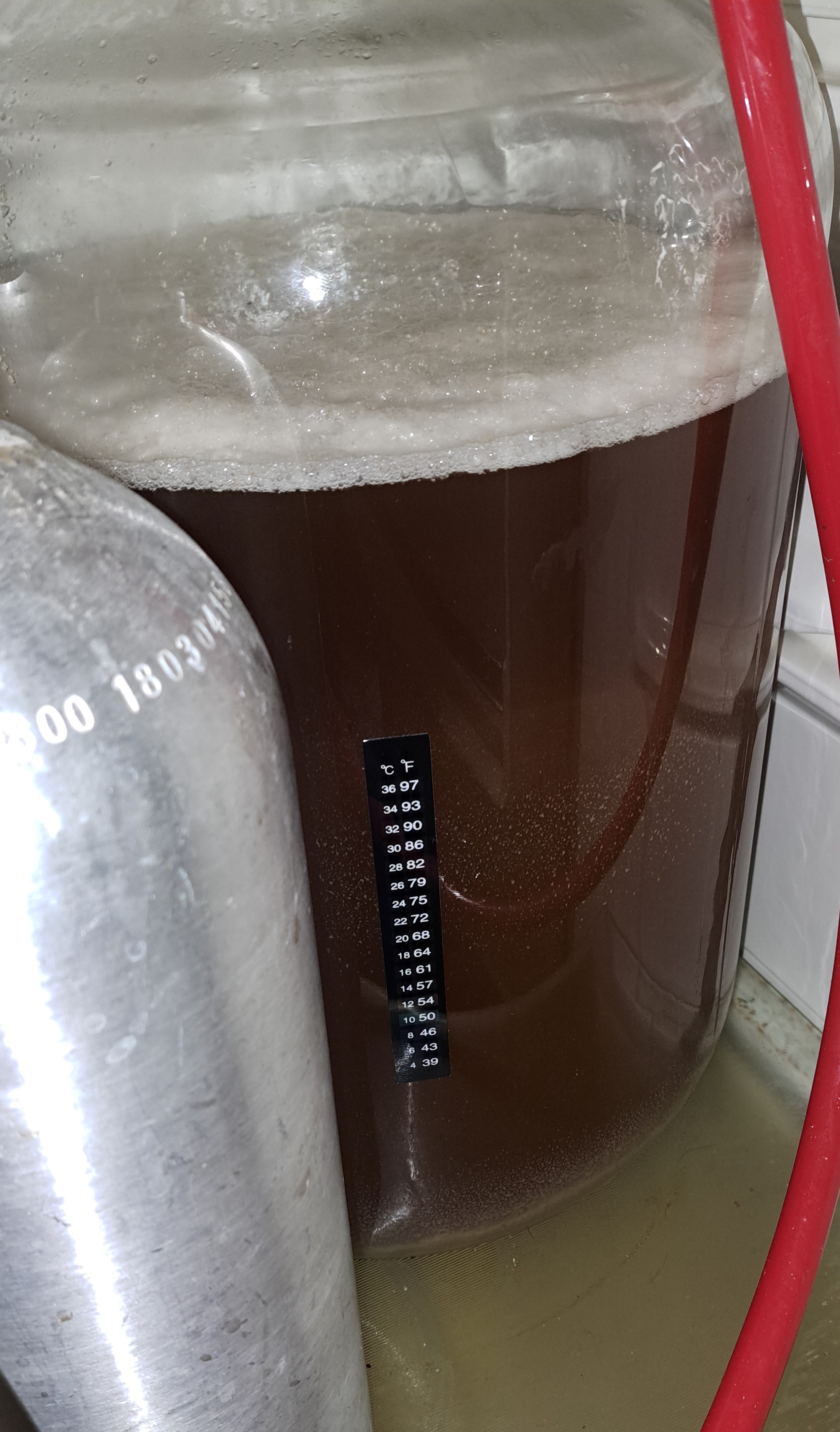

First lager in 20 years, Neufestbier (

) rocking now.

) rocking now.

First lager in 20 years, Neufestbier (

) rocking now.

) rocking now.

I use a small 30-plate DudaDiesel plate chiller. Keeping solids out of it is the best strategy, so I use kettle filters, and kettle hops are bagged. Even Irish moss should be bagged.Always reluctant to go with a plate chiller, but our shop has a used one at $79. Bit leery as they can't be broken down to be cleaned,

You can bake them in a 450°F oven, and that helps to sanitize and dry out any hop pulp or other solids that inadvertently got in there, but you can never be sure you get it all out. Reason is, the plates form parallel channels, so the wort or water bypasses obstructions, without putting any pressure on clogs to break them up or help flush them out.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

OK, thanks Island. I think I'm going to shy away and likely go with a CFC then, if I end up with a pump. Unless it would be prohibitively expensive, it would be nice if they made a plate heat exchanger that can be broken down, on the home level. Probably not doable on a commercial basis.I use a small 30-plate DudaDiesel plate chiller. Keeping solids out of it is the best strategy, so I use kettle filters, and kettle hops are bagged. Even Irish moss should be bagged.

You can bake them in a 450°F oven, and that helps to sanitize and dry out any hop pulp or other solids that inadvertently got in there, but you can never be sure you get it all out. Reason is, the plates form parallel channels, so the wort or water bypasses obstructions, without putting any pressure on clogs to break them up or help flush them out.

CFCs can be just as efficient, with much less maintenance.OK, thanks Island. I think I'm going to shy away and likely go with a CFC then,

In the remote chance a (partial) obstruction would form inside the CFC, you can push or erode it out by recirculating hot cleaner back and forth. I'd still put a coarse mesh filter before the exit port though.

Just don't store a CFC in an area that can freeze, unless you drain or blow out all the water. Even then...

I've been using that plate chiller for 15 years, with mixed feelings for the first 8-10. But the troubles ended once I kept all solids in the kettle by simply bagging or using mesh baskets.

Those large mesh bottom kettle filters, such as Hop Stoppers, will probably do a good job too. But they all seem out of stock, or perhaps even discontinued.

I haven't come across one yet. Even the smallest commercial one is much too big for homebrewing. The passages in those are probably much bigger too, so clogging may not be as much of an issue unless whole grain or hop flowers are sent down the pipe.Unless it would be prohibitively expensive, it would be nice if they made a plate heat exchanger that can be broken down, on the home level. Probably not doable on a commercial basis.

This is what I do. I found a cheap pump on amazon and I used it for both my IC and my keg and bucket washer. Cheap, easy and a few bags of ice from the local liquor store an I am at temp fairly soon. I use the time that I am chilling down to start my cleanup and sanitize my FV.Seeing as you're strained for time, if you can get it to low 60s, pitch and then throw in ferm chamber. Since you crashed the starter, the yeast will be in lag phase anyway for the time it takes to get your wort to the 50s in the ferm chamber.

In the future, when using an IC, you can fill a cooler with ice water and a pond pump to recirculate. It'll get the wort to 50 very quickly.

user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

There's a pump at Home Depot that seems to fit the bill at 500GPH, 1/2" tubing inlet ready to go (seems close anyway to the youtube vid @wepeeler posted - thanks again), but I'd prefer not to spend $64 on a pump if I can avoid it. Mind telling me which amazon pump you went with? Just didn't want to underpower the flow, as that's also key I would think, to the efficiency of the setup.This is what I do. I found a cheap pump on amazon and I used it for both my IC and my keg and bucket washer. Cheap, easy and a few bags of ice from the local liquor store an I am at temp fairly soon. I use the time that I am chilling down to start my cleanup and sanitize my FV.

user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

<<Bump on the pump options>>

Apparently HopStopper manufacturing was a one man operation and the one man retired.Those large mesh bottom kettle filters, such as Hop Stoppers, will probably do a good job too. But they all seem out of stock, or perhaps even discontinued.

Do bazooka screens just not cut it for pellet hops?

I use a cheapo pond pump from home depot ~15 years ago. It's a "Geoglobal FP300". "300 gph". With my little 25' stainless IC, it's mostly thermal transfer bound. If you have a copper or much longer IC, more flow might help.

user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

Great, thanks much.I use a cheapo pond pump from home depot ~15 years ago. It's a "Geoglobal FP300". "300 gph". With my little 25' stainless IC, it's mostly thermal transfer bound. If you have a copper or much longer IC, more flow might help.

user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

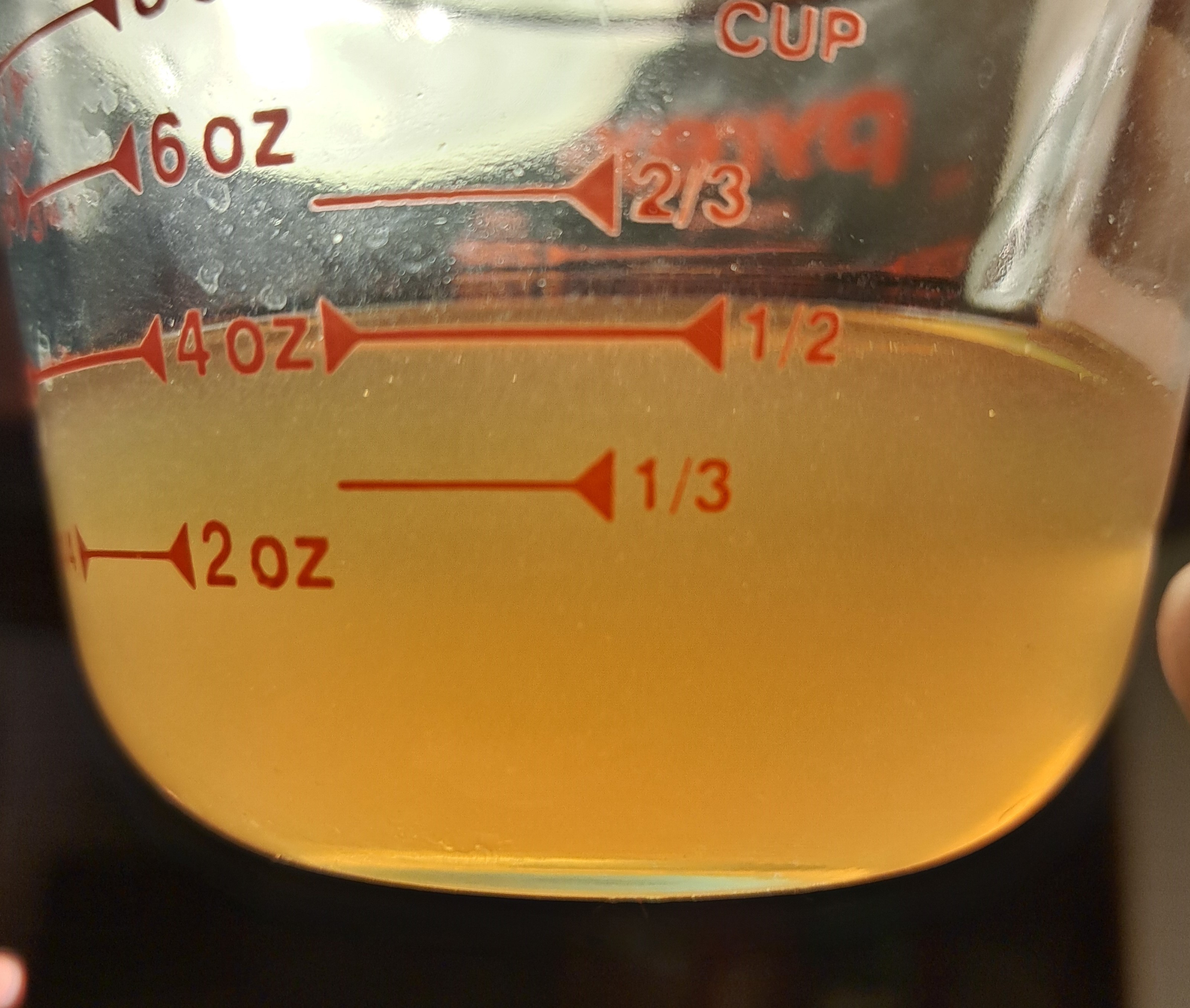

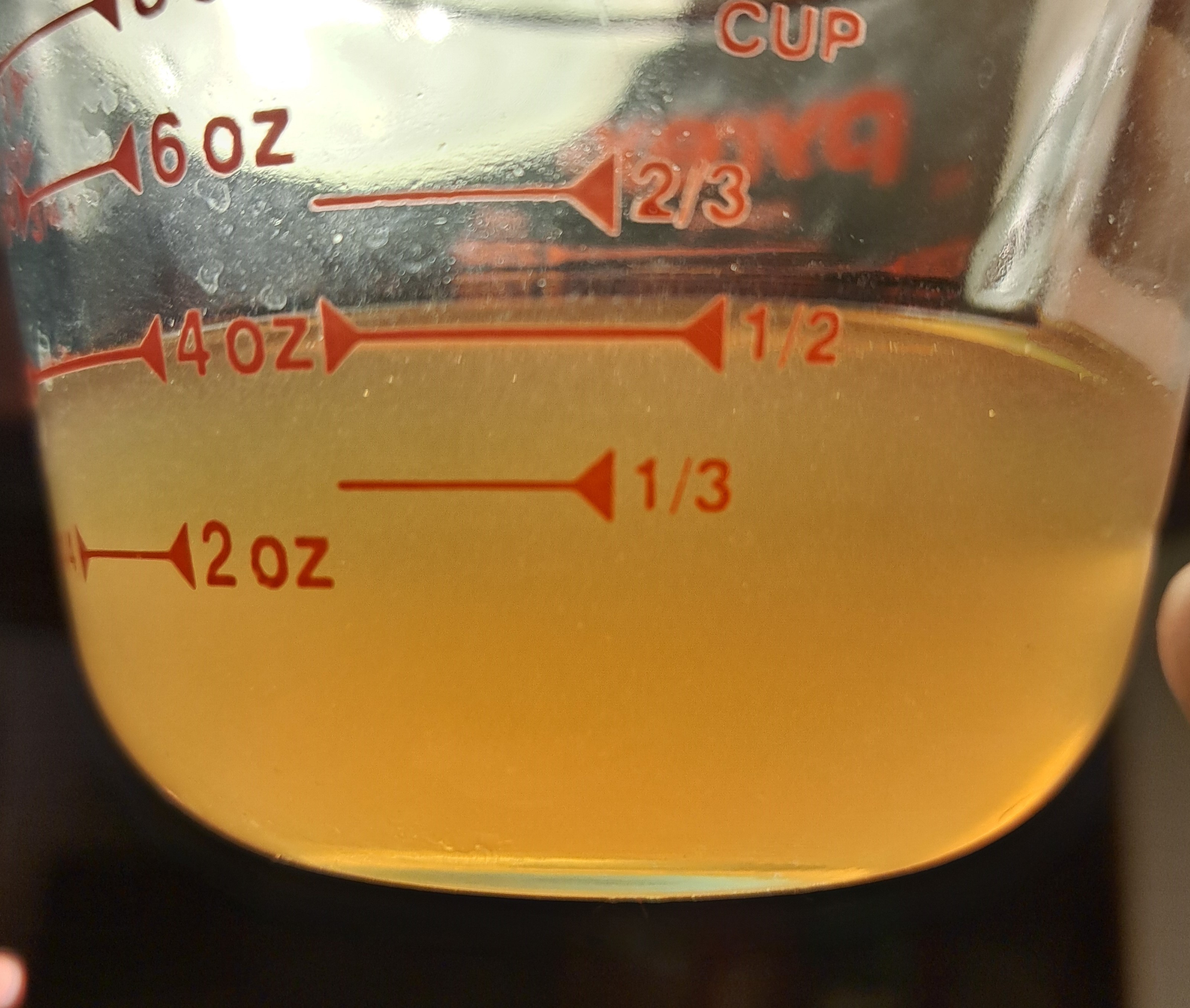

Well, pretty cool. Works perfectly, today a trial run for a pilsner brew tomorrow. Many thanks lads.

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 138

- Views

- 12K

- Replies

- 36

- Views

- 3K

- Replies

- 6

- Views

- 2K

Latest posts

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: IslandLizard

-

-

-

Spike Conical Heater fails again--second in 3 years--ideas?

- Latest: Indian_villager

-

-

-

-