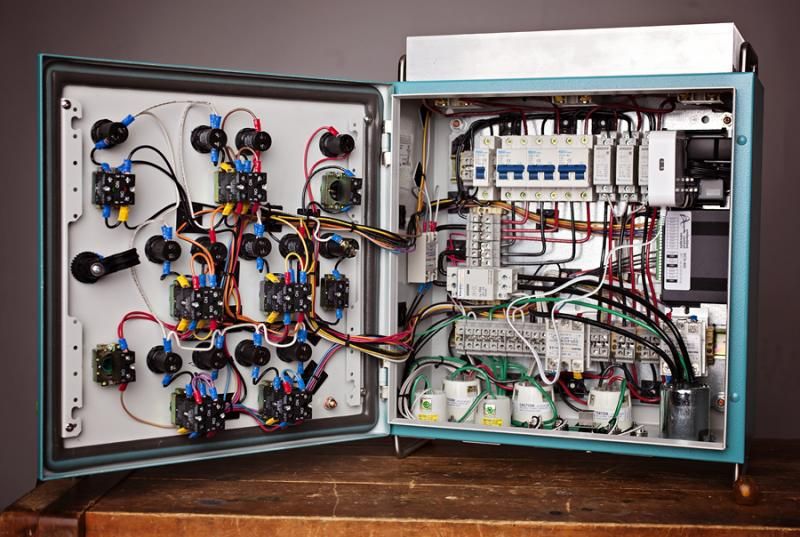

I made a mistake and had my control panel wired up with three L6-30 240v outlets to heat my heating elements.

My plan was to run my boil kettle and hot liquor tank with 5500w stainless elements I purchased from brewhardware.

For my RIMS tube I purchased the same 5500w element but had intended to run it at half power, 120v.

This is what happens when you don't actually plan everything out from the beginning. :cross:

My question is can I rewire my L6-30 outlet to deliver only 120v power? The outlet already being installed would leave a pretty big hole if I tried to put something else in there.

My box is supplied power from a 50amp breaker run through a spa panel to a 4 prong outlet as I'm already running 120v to my two outlets that run my pumps.

This is what happens when regular guys like myself try to do electric brewing

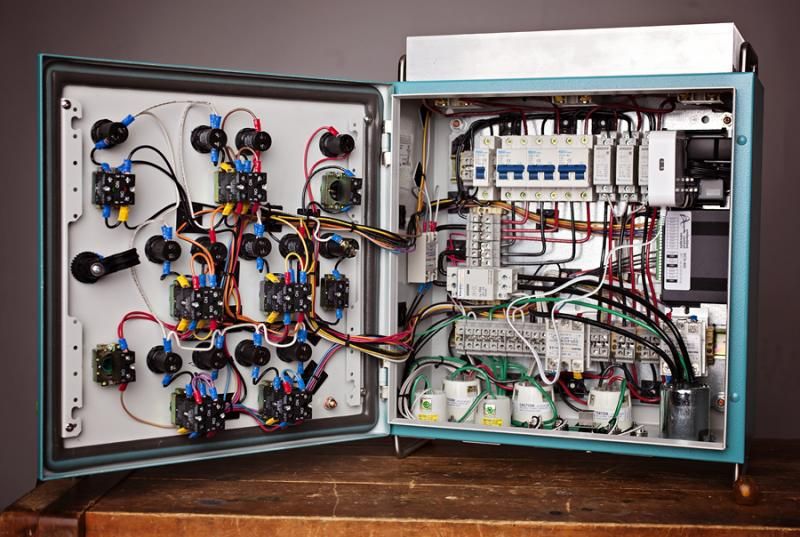

My plan was to run my boil kettle and hot liquor tank with 5500w stainless elements I purchased from brewhardware.

For my RIMS tube I purchased the same 5500w element but had intended to run it at half power, 120v.

This is what happens when you don't actually plan everything out from the beginning. :cross:

My question is can I rewire my L6-30 outlet to deliver only 120v power? The outlet already being installed would leave a pretty big hole if I tried to put something else in there.

My box is supplied power from a 50amp breaker run through a spa panel to a 4 prong outlet as I'm already running 120v to my two outlets that run my pumps.

This is what happens when regular guys like myself try to do electric brewing

Last edited by a moderator:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)