Holtbrew

Member

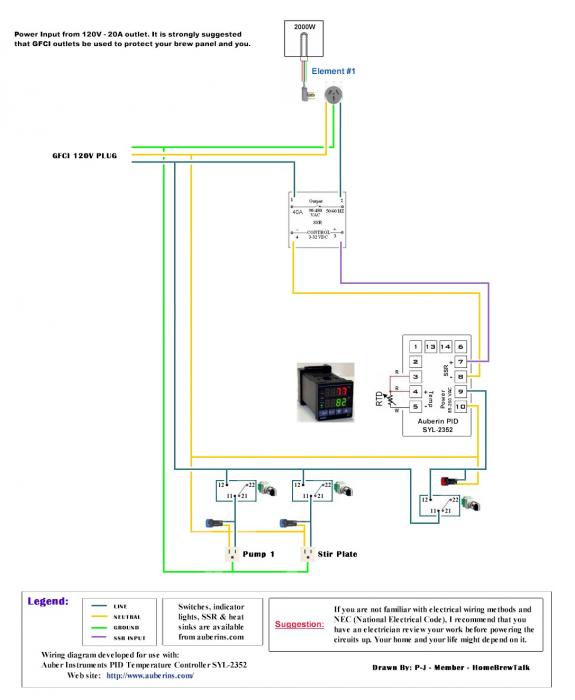

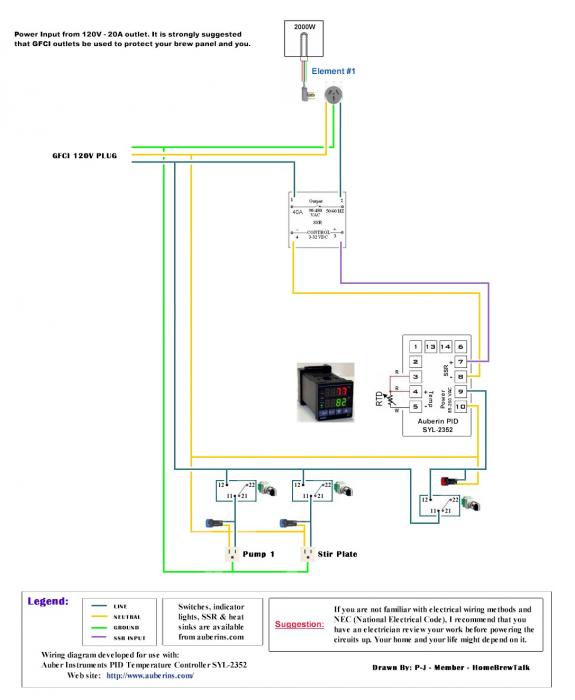

Hey guys, I've been testing out my simple 8 gallon single vessel 120V electric setup and I've run into a few issues. To start, it's very similar setup to one of PJ's diagrams (thanks PJ!) for a 2000W element (attached to this post), except without the stir plate and I added an additional switch for the element (placed before the 40A SSR).

The test run with water was going well until the auto tuning of the PID. I used the same RTD probe and PID controller as Kal and via his website on auto tuning the SYL-2352:

The temp I set was 152F for 6 gallons of water, and at 142F I set the At setting to 2. The whole time it "auto tuned" the SV was flashing "At" followed by "152" and the element fired continuously up to 152F and stopped. From here the element was off (according the "OUT" light on the PID), but the temp slowly rose, maybe 1 degree F every 5 minutes. All of this happening while the "At" and "152" are still flashing, and the A/M light was off the entire time (makes me wonder if I'm not actually auto tuning). Once it reached 161F I shut it down, no success.

My questions:

1) I realize SSRs can leak current, but is it enough to raise the temp 1 degree every 5 minutes? My vessel is aluminium, but the sides and lid are insulated with about 0.5" of foam. Note: the bottom is not insulated and sits on a kitchen stove top.

2) Has anyone experienced this auto tuning issue with the SYL-2352 PID? The differences when compared to Kal's instructions makes me think I'm doing something wrong.

Notes:

-I checked with a multimeter, the SSR is not fried in the closed position.

-Upon turning the element switch off (the one I added before the SSR), the temp on the PID stopped rising (indicating SSR current leakage?).

-The HLT water is being recirculated by a pump, and the RTD probe is inline (T connection) with the HLT out valve, like Kal's setup.

Thanks to anyone who can help.

The test run with water was going well until the auto tuning of the PID. I used the same RTD probe and PID controller as Kal and via his website on auto tuning the SYL-2352:

To perform auto tuning on the Hot Liquor Tank PID, do the following:

1) Fill your Hot Liquor Tank with water and set the Hot Liquor Tank PID to a typical mash temperature of around 154F. (See Step 3: Heat Strike Water from our Brew Day: Step by Step article).

2) Once the water is approximately 10 degrees below the 154F set temperature, set the At setting to 2. To do this, hold down the SET button on the PID for 3 seconds to enter programming mode, use the SET button to advance to the At (auto turning) setting, and then use the up/down arrow buttons to change the setting to 2. Once done, simply wait 10 seconds and auto tuning will automatically start.

3) For the next 20-40 minutes the PID will automatically turn the heating element on and off multiple times to see how fast temperature rises and drops in order to set the proportional, integral, and derivative parameters automatically. The A/M light will blink during auto tuning. Once auto tuning is complete the At setting will return to the default value of 3.

The temp I set was 152F for 6 gallons of water, and at 142F I set the At setting to 2. The whole time it "auto tuned" the SV was flashing "At" followed by "152" and the element fired continuously up to 152F and stopped. From here the element was off (according the "OUT" light on the PID), but the temp slowly rose, maybe 1 degree F every 5 minutes. All of this happening while the "At" and "152" are still flashing, and the A/M light was off the entire time (makes me wonder if I'm not actually auto tuning). Once it reached 161F I shut it down, no success.

My questions:

1) I realize SSRs can leak current, but is it enough to raise the temp 1 degree every 5 minutes? My vessel is aluminium, but the sides and lid are insulated with about 0.5" of foam. Note: the bottom is not insulated and sits on a kitchen stove top.

2) Has anyone experienced this auto tuning issue with the SYL-2352 PID? The differences when compared to Kal's instructions makes me think I'm doing something wrong.

Notes:

-I checked with a multimeter, the SSR is not fried in the closed position.

-Upon turning the element switch off (the one I added before the SSR), the temp on the PID stopped rising (indicating SSR current leakage?).

-The HLT water is being recirculated by a pump, and the RTD probe is inline (T connection) with the HLT out valve, like Kal's setup.

Thanks to anyone who can help.