One thing you could do to enlarge the holes. Lay out the bigger holes with a piece of cardboard. Once you go over it in your mind about 10 times, rent/borrow a 1/2" hammer drill and 1/4" & 3/8" bits. You should be able to rent/buy long enough drill bits to get through. Even if it won't quite go all the way through, you can make it work with 2 passes. Then, drill around the perimeter of the circle with the small bit making the holes 1/2" apart. Go back around with the big bit and enlarge the perimeter holes. Take a chisel and 4lb. shop hammer and connect the dots. Remember, you are going to slick down the outside with mortar or something stronger so even if the hole is ugly, you can fix it. That's such a nice room that it would be a shame not to have it as "perfect" as possible. Luck - Dwain

Good idea Dwain. I actually have a hammer drill (not sure if it's 1/2" - probably not) and bits of all sizes with a 12" extension rod. I'll try with the holes that are there now and if there's too much CFM drop I'll go with making one of the holes bigger (to 6" probably).

I've been thinking about the condensate hood. I have no need for anything too huge (I don't think). I'm thinking about having a shop make up stainless box something like this commercial unit:

Commercial stainless condensate hoods are crazy expensive ($700 to the sky's the limit) and most are too big anyway.

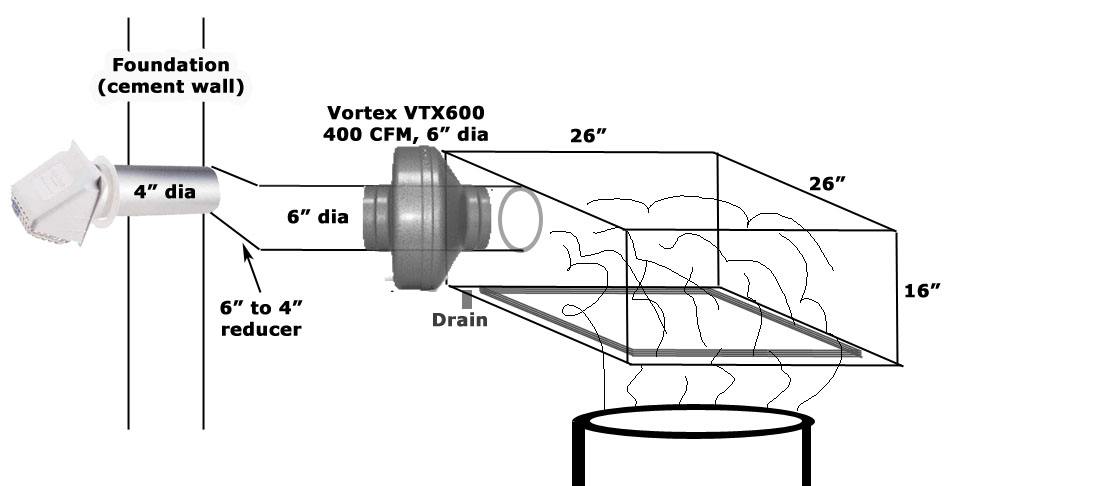

I'd exhaust out the side like this instead:

(Excuse the quality of the image... an artist I am not!)

Is exhausting out the side of this custom hood a problem? I only ask because every commercial unit vents out the middle top. It's a pretty small unit so I'm hoping it would be ok. I could see going out the side problematic if it was, say, 4 feet long.

It's basically a box without a bottom, but with a small 1" or so lip all around the inside bottom to catch condensation and a drain in the corner. Total distance from the custom hood to the outside is about 4-5 feet.

Does this make sense? I would simply drill 4 holes inside the "roof" near the corners and bolt it directly to the ceiling and then silicon caulk over the bolts to ensure no leakage.

Hopefully that would provide enough airflow. Unlike regular range hood fans the Vertex inline fans are supposed to be very good with static pressure meaning that smaller diameter duct and turns isn't going to severely reduce the CFM output.

If the airflow's not enough I could increase the wall hole diameter from 4" to 6" or exhaust out the other 4" hole too. I really hope neither is needed.

The other thing is that the hood doesn't even need to be stainless. Any sort of non-organic material will work for a hood (acrylic, formica, etc),

since you don't need to be concerned about flame/heat/grease from a grill top. I could build something temporary myself to see how it performs first.

Kal

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)