So how did the beer turn out?

I've kept this as a plan, but for now I figure I better just work on brewing in general (all-grain is still new, batch #2 coming up with an IPA).

I will switch to a RIMS system, the question is whether it will be RIMS or HERMS, well technically they are all HERMS right?

My question for this system will involve something with a very stepped mash,

like a good oatmeal stout, or wheat beer. How do the steps go, and how are the results? I've read the recommended 2°F/min, does this perform faster or slower?

-Mac

I had 24.5 lbs of grains and 7.5 gallons of water and I ending up filling up the 10 gallon Gott cooler to the top.

I mashed in at 122F and then set the PID target to 153F. Once it reached 153F, I held it at 153Ffor an hour (just let it run), and then I set the PID to 167F and once it it hit 167F, I held it at 167F for 15 minutes. I then batched sparged, by alternating the draining of some of the wort into the copper and replenishing with hot water. I closed the dump valve until I see the circulating mash running clear after the water addition. I repeated this until I collected 12 gallons for the boil.

I achieved 0.5 F degree rise per minute running with pump wide open (max flow), opposed to the 1.8F/minute reported to be used for programmed infusion mashing for some Belgians in Brewing:science and Practice woodhouse. They also use a 1F/minute in some of the tests on yield.

I will switch to a RIMS system, the question is whether it will be RIMS or HERMS, well technically they are all HERMS right?

All of them recirculate, but the HERMS applies heat indirectly to the pipe rather than putting the heating element in the flow of the mash.

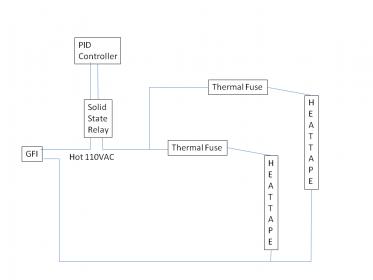

The Heat tape approach outlined in this thread is similar to the HERMS in that the heat is applied to the outside of the pipe rather than putting the heating element in the flow.

You could go with more heating tape or more elements, but I was shooting for < 80% of a 15 amp circuit for the whole system to make sure it is safe.

My current plan is to change out the PID I have for a PID with Ramp-Soak so I can set my schedule and walk away.

The weekend brew sessions went well, with 10 gallons of a Dale-Pale-Ale clone and 5 gallons of an IPA being cycled through the system. The 5 gallon batch heat rise rate was about the same.

So far I have put > 10 Five gallon batches through the various versions of the system, and 2 ten gallons batches.

I plan to adjust flow rate/turbulence in the heaters (insert a coil of wire to break up laminar flow to see if I can improve the heat gain).

I have been having really good luck with it, and I think I have been making more consistent beers.

Please let me know if you have any more questions or if I can be clearing on any of the build details.

As always use a GFCI

Joel

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)