CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

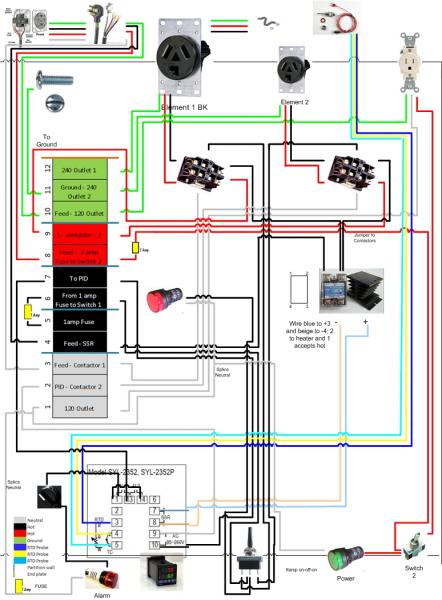

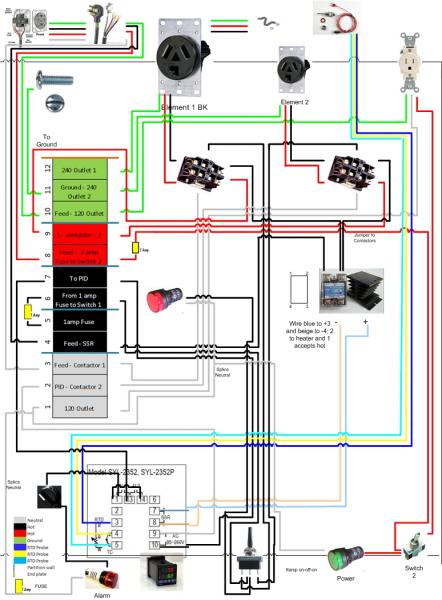

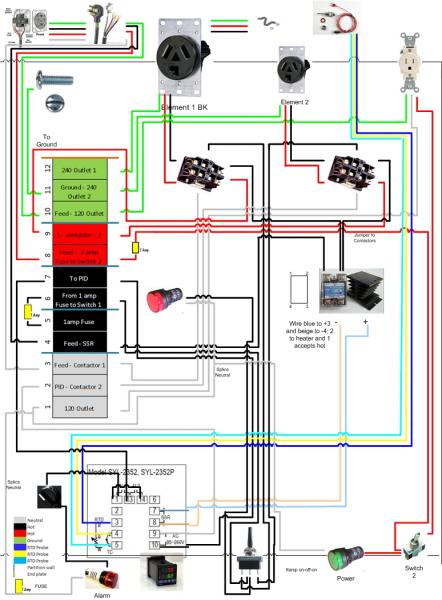

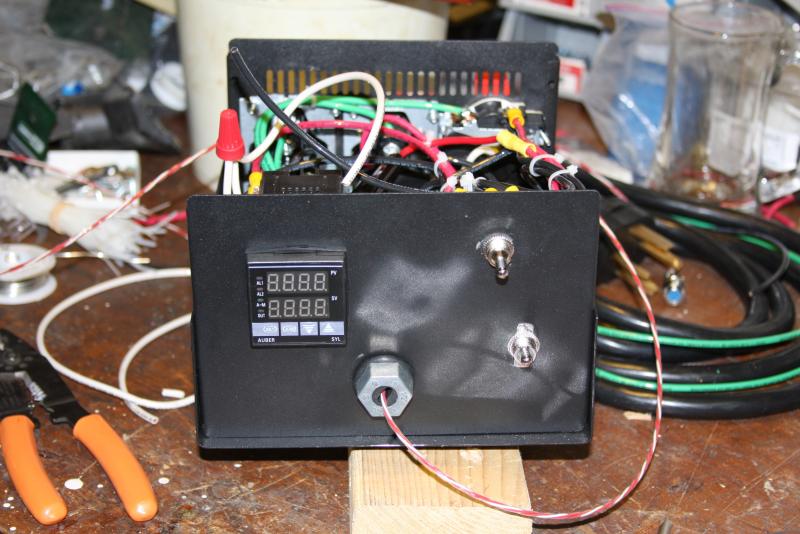

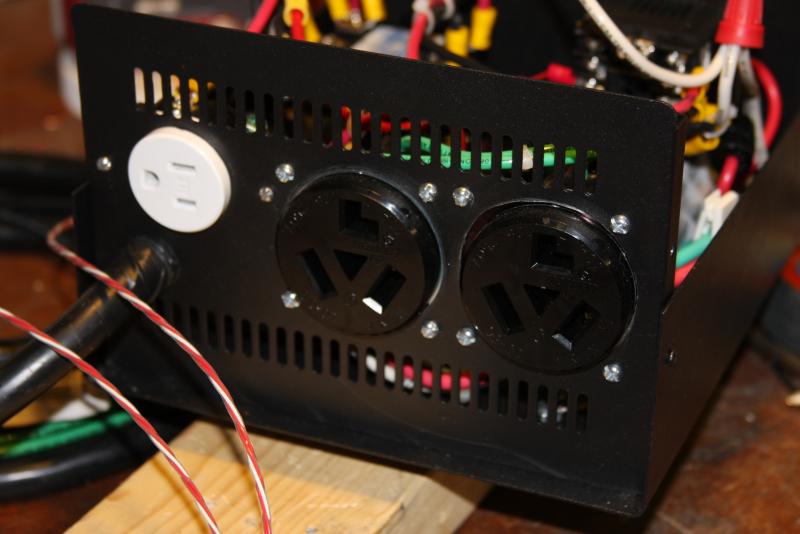

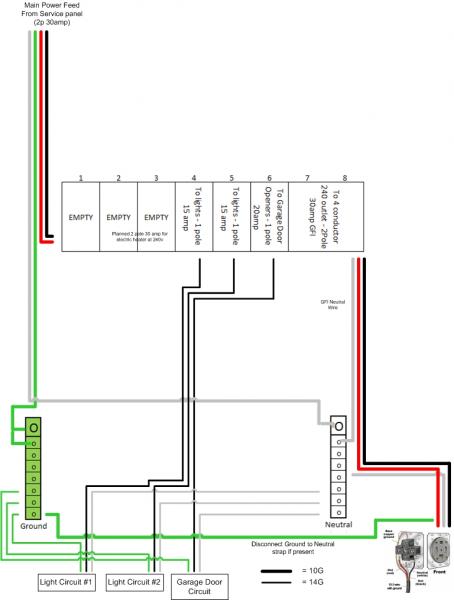

so something like this - pending the alarm. Or... daisy change the two lights, then two contactors then separate for alarm (if I end up getting an alarm  .

.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Careful with using a hole saw as it will cut a 'not so clean' hole. I'd suggest using a Step Bit to do the job. There is a Harbor Freight near you and the tool is fairly cheap ($20).I actually haven't cut a hole in my kettle yet. I have a hole saw and will be going that route because I can't get my hands on a greenlee just yet.

...

It should cut a very smooth hole. I have a set and use it often. I'd drill or punch an undersized hole first and then use the step bit to bring it to size. Lots of pressure, oil and go slow. You do not want the bit to spin freely.

Ok "Mad Scientist" I'd like to see pictures of your results when you get it done. I know you will be sucessful and pleased with the results. But - Pictures would be nice.Cool - I will pick up the step bit and use the punch to create a "pilot". Those punches make perfect circles.

Thanks for the advice PJ and Bruin!

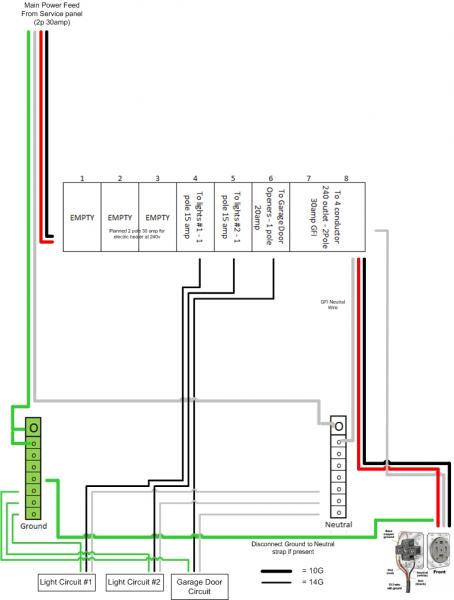

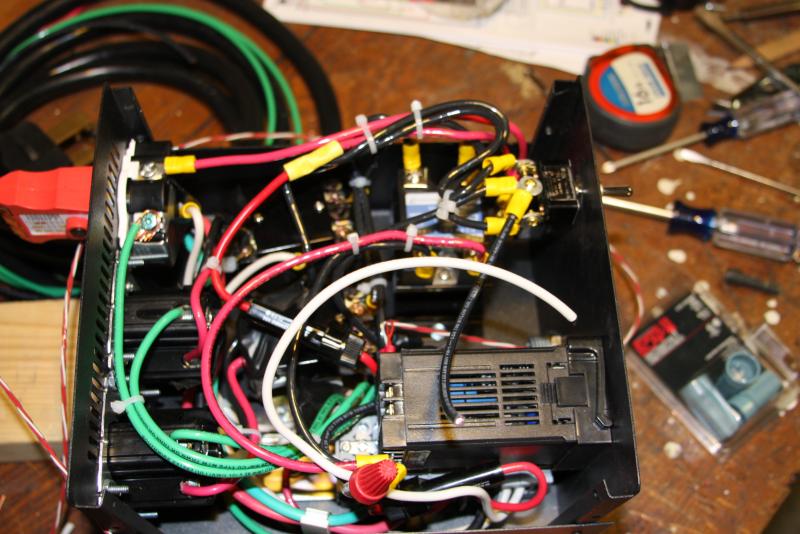

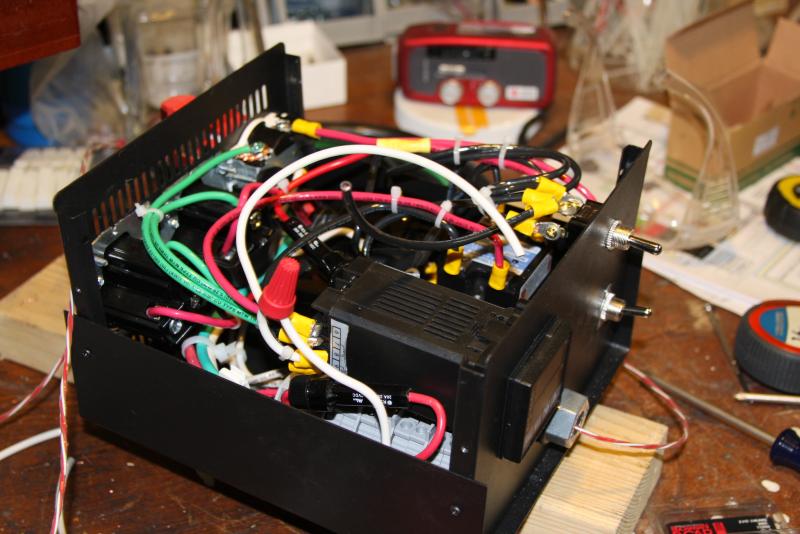

the curly wire attached to the breaker should go to the neutral bus in your panel, but the white wire that feeds out to your brewery receptacle should not come from the neutral bus. It needs to be attached to the GFCI breaker. That breaker should have a place to attach the two hot (red and black) as well as a place to attach a neutral, plus the pigtail neutral wire that is already attached to it.