Ok, so I did the first experiment I proposed earlier. I made a beer with a very simple grain bill that I mashed in 3.5 gallons of water, followed by a dunk sparge in 3.5 gallons of water. I squeezed the bag when I lifted it out of the mash water, then again when I lifted it out of the sparge water. I took gravity measurements at more or less every step.

I almost feel like I screwed something up though. I was extremely meticulous with all my measurements, moreso than I have been on any previous beer, yet my efficiency came out unbelievably high. I also stirred vigorously before taking my samples to hopefully minimize any stratification of the wort into multiple layers of differing densities, so that shouldn't be an issue. I'd be the first to congratulate myself for it if I actually thought it was accurate, but I don't really trust it. I'd appreciate it if anyone could find where I messed up and let me know lol.

The recipe:

Dunk 'n Squeeze Blonde

8.25lbs pale 2 row

2lbs minute rice

.5oz crystal (boil 60 min)

.5oz Willamette (boil 60 mins)

mash in 14 quarts of water for 60 minutes at 150F

Heat 14 quarts of water to 168 while mashing

At the conclusion of the mash squeeze out grains and drop them into the bucket of 168 degree sparge water.

Stir once, wait 10 minutes, stir again, then lift bag out

Squeeze bag until you're at 14 quarts again

Combine worts in boil pot

Boil 60 minutes adding hops as per schedule

Cool wort, add to fermenter, pitch yeast when ready

I had beersmith set to 75% efficiency because that was about what I hit on my last brew day. At that efficiency the numbers are:

OG - 1.050

Bitterness - 16.6 IBUs

Color - 3.5 SRM

ABV - 5.3%

Batch size - 5.42 gallons

The slightly weird batch size is there because it's what I needed for beersmith to give me my 3.5 gallon sparge amount. I wanted what I was doing to be reflected as accurately as possible in beersmith. To that end, I also changed the grain absorption rate to the same as it would be in BIAB since I would be squeezing the grains.

That's the grains, carefully measured on a kitchen scale to be exactly 10.25lbs.

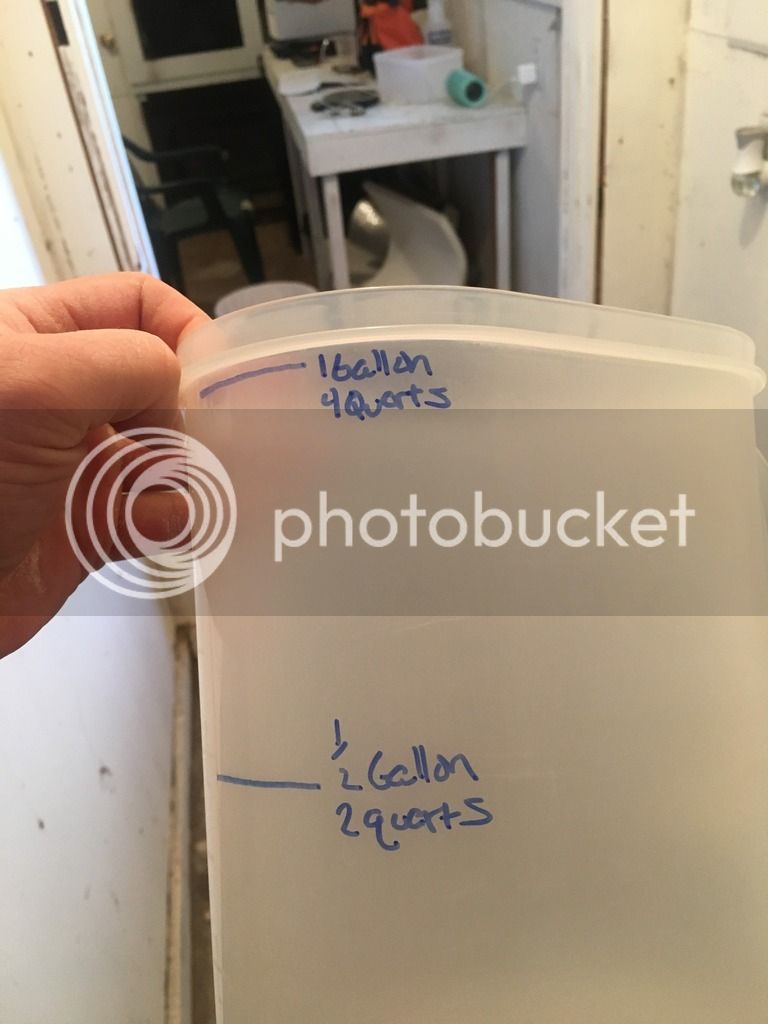

I knew getting my water volumes correct was going to be important, so I used this precision measuring device to draw my mash and sparge water.

Shown here is me filling it up with my fancy new water filter. This IS my first brew using filtered water, but I can't see how that would make such a large difference in efficiency.

I knew I was on to something when I pretty much nailed my mash temperature. I forgot to take a picture of the post mash temp, but it was 144 degrees, or a 6-7 degree loss over 60 minutes. I chalk that up to the low volume of the mash. The full volume mash that will eventually make up the second half of this experiment should retain heat better.

Now for the good stuff. This is the post mash gravity AFTER squeezing the bag, but BEFORE any sparge water was added. This already seemed a bit high to me. That 1.076 measurement was also taken at 100F, so it converts to 1.081 at the hydrometer's calibration temp. Any idea what's going on there?

This is the gravity of my sparge water after removing the bag, but before squeezing the bag. Now the reason it's higher than mongoose's is likely because I put the grains in, stirred, left them for 10 minutes, stirred again, and then removed the bag. A bit more than just a dunk, but I wanted to give the process a fair shot. That sample was measured at 106 degrees, so it converts to 1.024 at the hydrometer's calibration temp. Not bad

This is the sparge water AFTER squeezing the bag to recover my water volume. It looks very close to the pre squeeze number, likely because of all the stirring and the 10 minute rest I gave it. I'm calling that one 1.020, which converts to 1.026 at the hydrometer's calibration temp.

This is the combined wort, or essentially the preboil gravity. 1.046 would be right in range normally, but if you take into account the fact that this measurement was taken at 98 degrees it becomes 1.051 at the hydrometer's calibration temp. That's already more than the post boil gravity is supposed to be! I definitely knew something was up at this point.

and finally the post boil gravity. I failed to record the temperature that this measurement was taken at, but considering that I took the sample and placed it in the fridge for a little while before measuring it, I'm guessing it was somewhere in the 70-80 degree range. It could be a couple of points in either direction, so I'll just call it 1.064.

So my numbers are as follows:

Strike gravity - 1.081

pre-squeeze sparge gravity - 1.024

Post squeeze sparge gravity - 1.026

Pre boil gravity - 1.051

OG - 1.064

When I input these numbers into beersmith, it says that I've achieved a whopping 95% efficiency. My volumes ended up right, with a little less than 5.5 gallons in the fermenter. Everything was measured to the best of my abilities, and I didn't really do anything that special. Can anyone account for this?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)