marshallwms

Junior Member

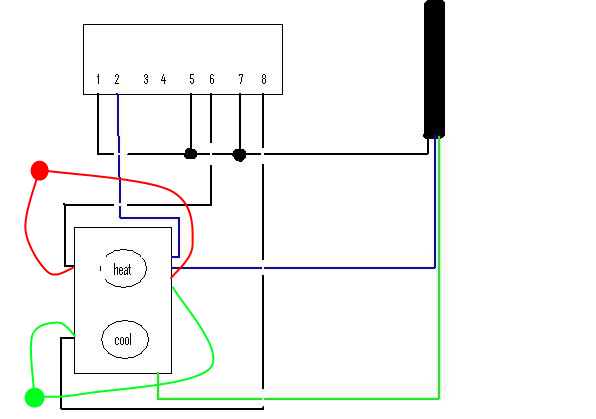

I would remove the probe wires, retwist them, and reinstall. Make very sure there are no stray strands that could cause a problem and are securely tightened. The other wiring needs to be modified as outlined above - move the green ground wire to the green screw on the outlet. That wiring will not cause an EE error. Only the probe should do that. If you are concerned, remove the wires from 5, 6, 7, and 8 that go to the outlet.

It is possible you have a defective (shorted) probe. If so it would be the first I have heard of. I am building my 6th controller and have never had a problem.

It is possible you have a defective (shorted) probe. If so it would be the first I have heard of. I am building my 6th controller and have never had a problem.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)