This thread is so informative thanks!

My STC-1000 is on a slow boat from China as we speak. I want to ask has anyone used one to control a water pump?

I ask because SWMBO won't allow me another fridge for Beer, apparently one chest freezer for beer purposes is enough... I don't get it but she makes the rules.

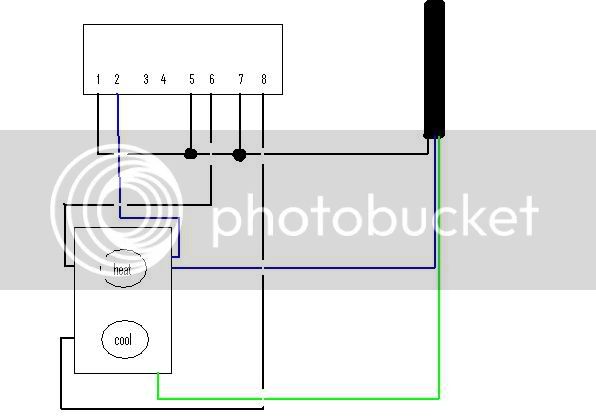

So my plan is to make a fermentation chamber out of insulation and plywood, put an ice chest on top, put a pump in that hooked up to the STC-1000 and use frozen milk jugs full of water to cool water pumped into the fermentation chamber.

I plan on putting a coil of copper tube inside a 3" pvc pipe with a computer fan circulating air through the tube as a heat exchanger inside the chamber.

Does this seem like a workable plan?

My STC-1000 is on a slow boat from China as we speak. I want to ask has anyone used one to control a water pump?

I ask because SWMBO won't allow me another fridge for Beer, apparently one chest freezer for beer purposes is enough... I don't get it but she makes the rules.

So my plan is to make a fermentation chamber out of insulation and plywood, put an ice chest on top, put a pump in that hooked up to the STC-1000 and use frozen milk jugs full of water to cool water pumped into the fermentation chamber.

I plan on putting a coil of copper tube inside a 3" pvc pipe with a computer fan circulating air through the tube as a heat exchanger inside the chamber.

Does this seem like a workable plan?

. Please advise.

. Please advise.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)