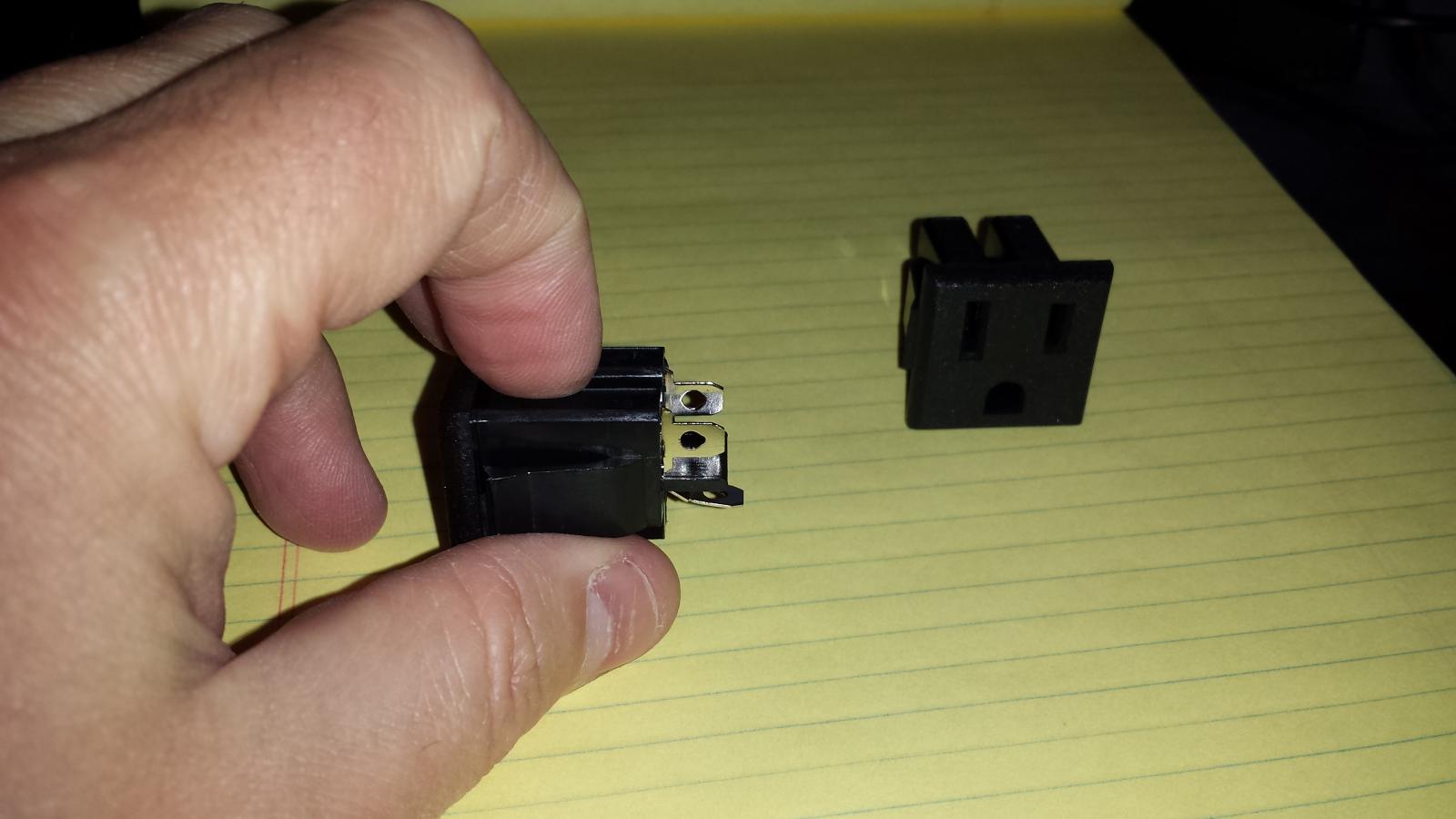

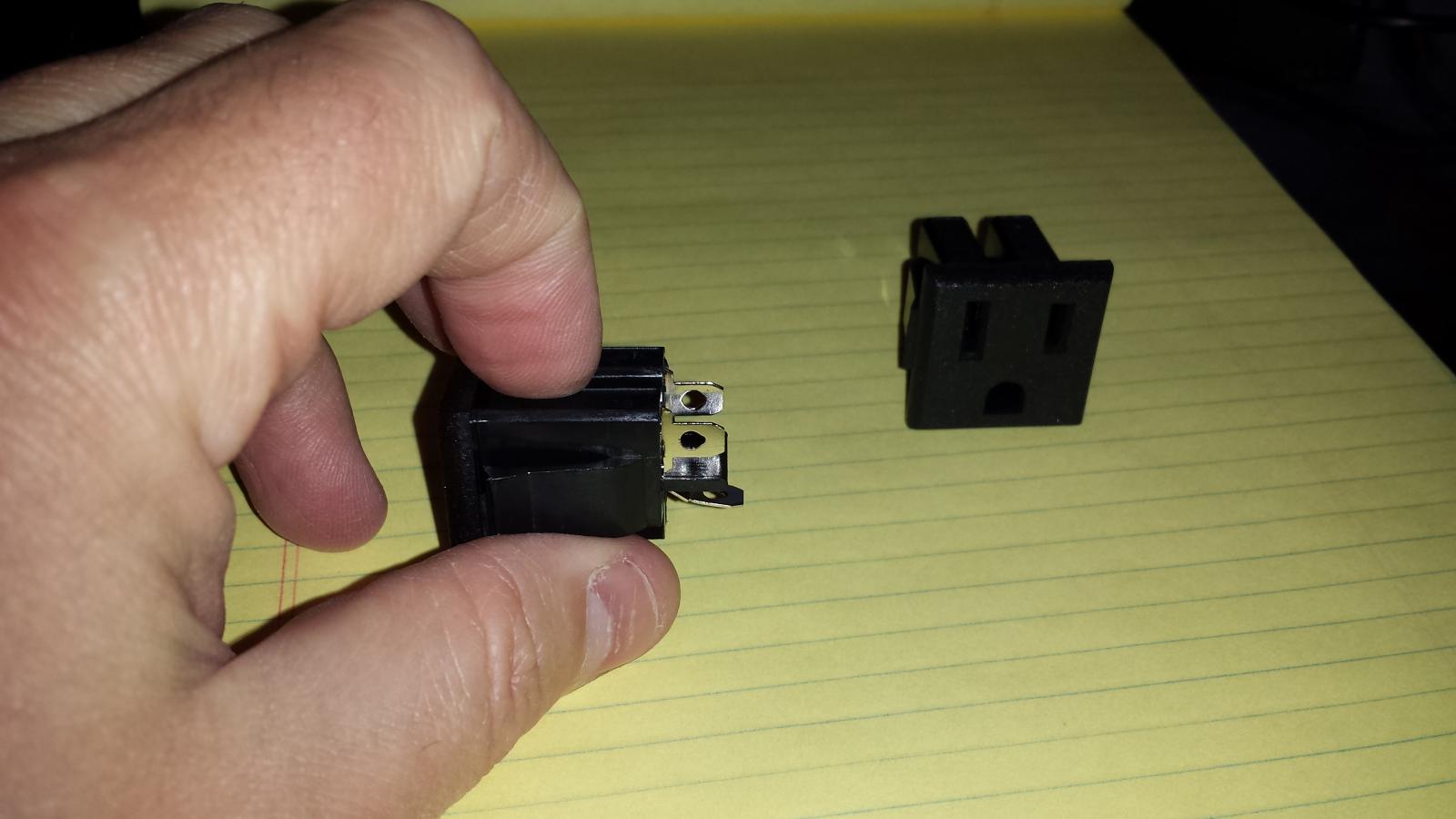

This should be an easy question for those more electrically inclined than myself. I am getting ready to wire up my STC-1000. I am going to use 2 single outlets for the heat and cool devices instead 1 dual outlet. Here are the outlets I bought. My question is what is the best way to attach wires to them? I was thinking of just putting the wires through the holes and bending them but that makes me think something could go wrong down the road since they aren't really secure. Are there some type of terminal connectors I can put on the wires so that they snap onto the outlet leads (not sure if leads is the right term here)? Thanks.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)