I’ve got a 5 gallon batch that’s been fermenting for an event on Saturday, so last night I wanted to dry hop with a little bit of cryo pellets and while doing that, the brew jacket rod and sleeve slipped out of the bung … bam into the fermonter. Ef ef ef. DON’T DO THAT! With Starsan on my hands I reached into grab the unsanitary end which did not touch the beer, thankfully rinsed and dried it throughly. I had recently cracked my 3 gallon fmonster so I checked for a leak on this one. Whew, can’t wait to get this one kegged and out of here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Don't Do That.

- Thread starter TAK

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Don't grab a pack of bittering hops out of the fridge, check the AA and say "that's perfect" but neglect to notice that it's a 2 oz package before you dump the whole thing into the boil. Guess my English pale ale is an English IPA now.

Use a pistol grip hose nozzle to rinse the inside of the bottles if it fits snugly using city water presure- yea, they explode -DONT DO THAT.

- Joined

- Nov 26, 2013

- Messages

- 9,924

- Reaction score

- 24,093

Kids, public safety announcement here.

Check yer defaults.

On everything.

Always.

Then check then again. (I feel like Nemo's dad darting in and out of Annie the Sea Anemone multiple times)

Anyway, if you use an STC1000+ and have ramp schedules programmed, and you write them down, but you edit them sometimes and forget to write down starting temp for instance, then this can happen.

"Set ramp to 68-74 over 48 hrs" but step 0 temp was still 64 not 68 as written...

Don't do that.

Funny side story, I had *JUST* had a convo with @day_trippr about defaults and checking them not 48 hrs ago.

Some people just cannot be trusted with tech.

Check yer defaults.

On everything.

Always.

Then check then again. (I feel like Nemo's dad darting in and out of Annie the Sea Anemone multiple times)

Anyway, if you use an STC1000+ and have ramp schedules programmed, and you write them down, but you edit them sometimes and forget to write down starting temp for instance, then this can happen.

"Set ramp to 68-74 over 48 hrs" but step 0 temp was still 64 not 68 as written...

Don't do that.

Funny side story, I had *JUST* had a convo with @day_trippr about defaults and checking them not 48 hrs ago.

Some people just cannot be trusted with tech.

InspectorJon

Well-Known Member

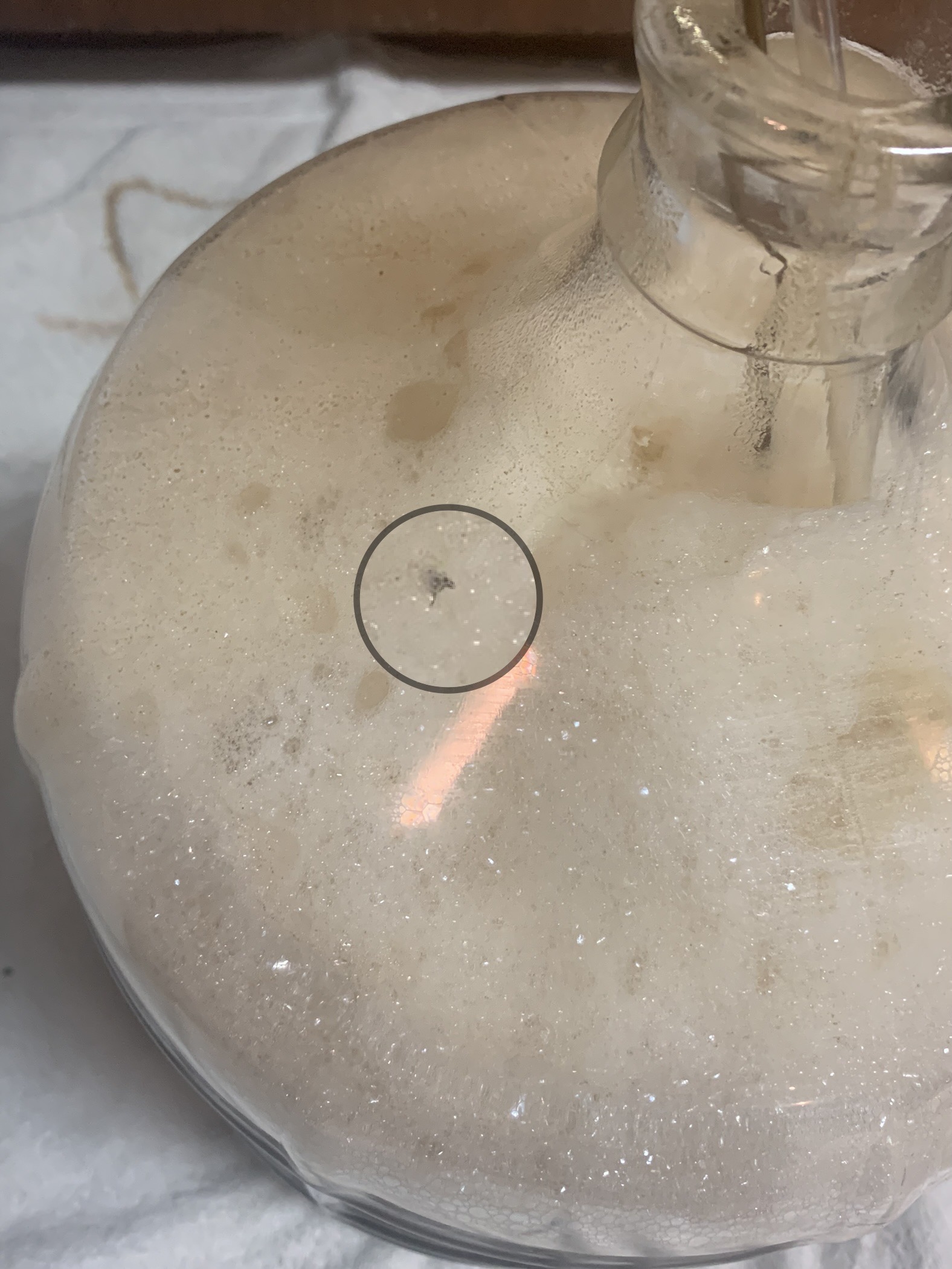

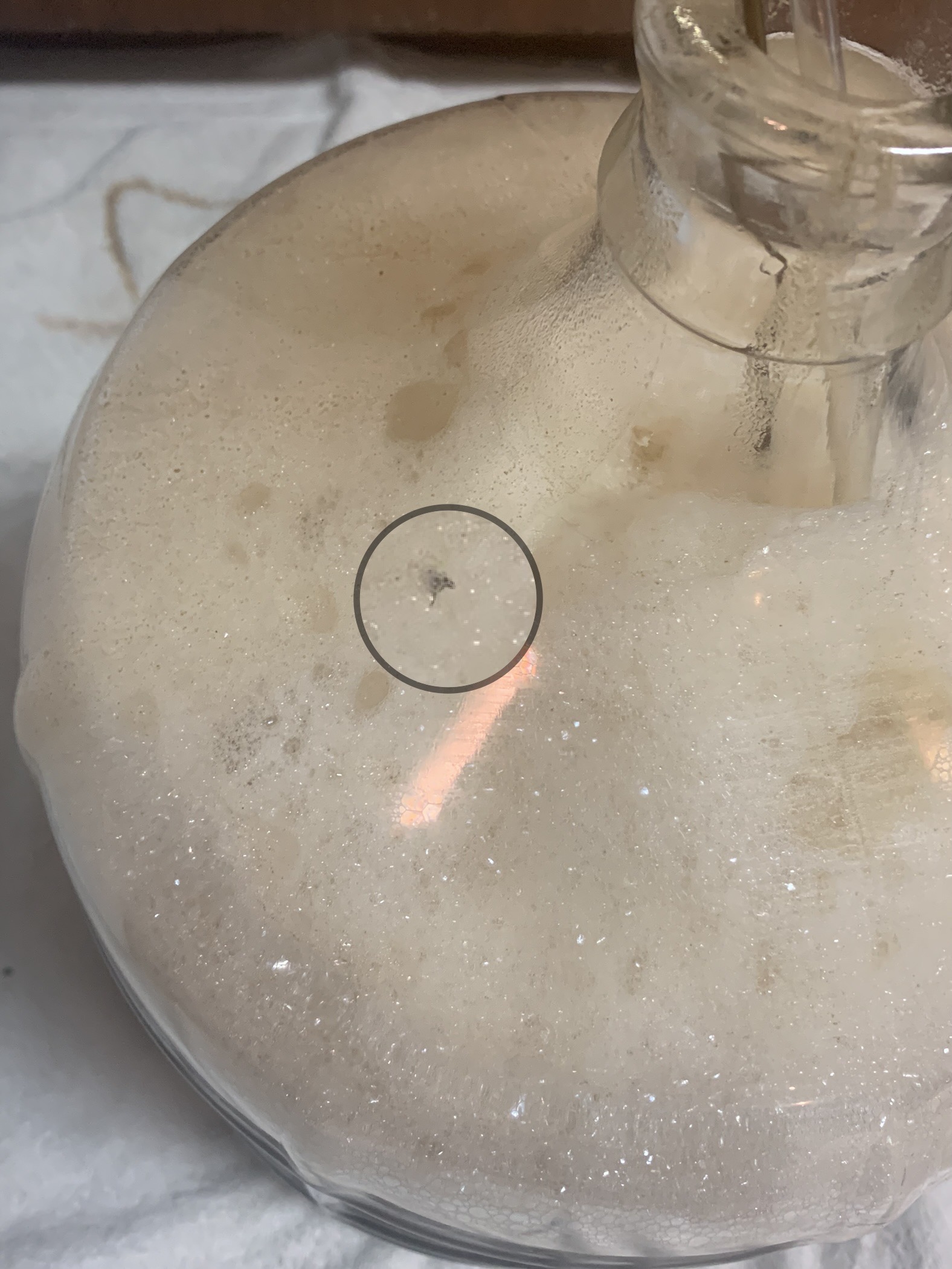

Pitch yeast and see a fruit fly swimming in the foam from aerating the wort

You've got to tell us - what did you do?Pitch yeast and see a fruit fly swimming in the foam from aerating the wort View attachment 831346

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

I guess you made a fruity beer then.

Don't double-check the level of vodka in your airlock, not noticing that there was suck-back when it cooled to fermentation temperature. Don't get concerned about the lack of bubbles, because sometimes that doesn't happen when we're watching. Don't worry about the beautiful smell of fermentation that filled the garage, because that's what's supposed to happen. DO notice the beer was open to the atmosphere for a week and a half.

- Joined

- Feb 16, 2012

- Messages

- 4,650

- Reaction score

- 7,077

- Location

- At home, in the brewery in Maryland.

Not a problem. It's all protein. The alcohol will sanitize it, after it's killed the little bugger. Look on the bright side: he'll die happy.Pitch yeast and see a fruit fly swimming in the foam from aerating the wort View attachment 831346

It's probably doesn't matter anymore, but have you tried to retrieve it?Pitch yeast and see a fruit fly swimming in the foam from aerating the wort

I would probably use a bendable metal wire with a small fabric pad on the end.

Once the yeast is established and fermenting away, the acetobacter on the fruit fly may not have much chance in that environment.

Fruit flies really don't eat or drink much.

- Joined

- Nov 26, 2013

- Messages

- 9,924

- Reaction score

- 24,093

Whatever you do, don't grab it by the wings and scream, "SPIT IT OOOT, YA WEE BUGGER!".

(c'mon; I can't have been the only one who immediately heard that joke in their heads)

(c'mon; I can't have been the only one who immediately heard that joke in their heads)

InspectorJon

Well-Known Member

It's probably doesn't matter anymore, but have you tried to retrieve it?

I would probably use a bendable metal wire with a small fabric pad on the end.

Once the yeast is established and fermenting away, the acetobacter on the fruit fly may not have much chance in that environment.

I was able to fish it out with the aeration setup. Pitched yeast right after. It was bubbling strong this morning. Hoping for the best. It's supposed to be a 8.5% porter. I hope it doesn't turn into a mixed fermentation. The peach tree in the back yard was very productive this year and some fruit flies came in with the fruit.

You need to come up with a fruit fly related name for your beer now.

TheBluePhantom

Brewing for sport

Fruit fly porter at 8.5%. That will definetely have a buzz!

Hey, it needed to be said...

Hey, it needed to be said...

Lampy

Well-Known Member

I wanted to experiment a little and try making a rice beer (50:50 two row and white rice). So I decided to pre-(over)cook the rice by putting 1.5 lbs + 1 gal water in my instant pot, filling it about 80% to "Max Fill".

When depressurizing it went ok at first, but then it started spewing thick white goo that oozed all over the top of the instant pot and the countertop. Took about 30 mins and some disassembly to clean up...

DON'T DO THAT! Should have used less water, but I thought it was an easy way to heat up the water for the mash.

When depressurizing it went ok at first, but then it started spewing thick white goo that oozed all over the top of the instant pot and the countertop. Took about 30 mins and some disassembly to clean up...

DON'T DO THAT! Should have used less water, but I thought it was an easy way to heat up the water for the mash.

Your misfortune made me chuckle. For that I apologize.I wanted to experiment a little and try making a rice beer (50:50 two row and white rice). So I decided to pre-(over)cook the rice by putting 1.5 lbs + 1 gal water in my instant pot, filling it about 80% to "Max Fill".

When depressurizing it went ok at first, but then it started spewing thick white goo that oozed all over the top of the instant pot and the countertop. Took about 30 mins and some disassembly to clean up...

DON'T DO THAT! Should have used less water, but I thought it was an easy way to heat up the water for the mash.

InspectorJon

Well-Known Member

The method you describe should work if you let the instant pot cool down before opening the release valve. That would add some time to the process but be easier than cleaning up the mess. Instant Pot refers to this a Natural Release. Once the cooking cycle is over turn the appliance off and wait for the sealing ring to drop on its own. This might take half an hour with a pot full of liquid.I wanted to experiment a little and try making a rice beer (50:50 two row and white rice). So I decided to pre-(over)cook the rice by putting 1.5 lbs + 1 gal water in my instant pot, filling it about 80% to "Max Fill".

When depressurizing it went ok at first, but then it started spewing thick white goo that oozed all over the top of the instant pot and the countertop. Took about 30 mins and some disassembly to clean up...

DON'T DO THAT! Should have used less water, but I thought it was an easy way to heat up the water for the mash.

Lampy

Well-Known Member

Yeah, I am familiar with the feature but was just impatient and not expecting the starch tsunami. Maybe next time, if this turns out good!The method you describe should work if you let the instant pot cool down before opening the release valve. That would add some time to the process but be easier than cleaning up the mess. Instant Pot refers to this a Natural Release. Once the cooking cycle is over turn the appliance off and wait for the sealing ring to drop on its own. This might take half an hour with a pot full of liquid.

- Joined

- Feb 16, 2012

- Messages

- 4,650

- Reaction score

- 7,077

- Location

- At home, in the brewery in Maryland.

I’d be worried that the PRV might get clogged and create a burst hazard.The method you describe should work if you let the instant pot cool down before opening the release valve. That would add some time to the process but be easier than cleaning up the mess. Instant Pot refers to this a Natural Release. Once the cooking cycle is over turn the appliance off and wait for the sealing ring to drop on its own. This might take half an hour with a pot full of liquid.

Ahem,I’d be worried that the PRV might get clogged and create a burst hazard.

Actually, the pressure is regulated by a weighted conical pin that fits atop a hollow tube with a small inner diameter. The area of the passage and the mass of the regulator generate ~1 atmosphere of pressure differential before it overcomes the weight, and venting occurs. Should the weight become blocked or jammed, a few additional kpa will cause the silicone cap seal on the end of the float valve, which serves as a burst-disk, to rupture and venting occurs. Should that fail, additional pressure forces the inner pot down onto an overpressure sensor in the base which will open the circuit for the calrod heat element, and pressure will stop rising. It's a variable sensor as well, the mechanism which enables 2 or more pressure settings. Should that sensor fail, the silicone main gasket is forced to vent via fin seal flexure, causing excess pressure to vent around the perimeter of the lid, safely directed downward into the condensate channel. Should all of the above somehow fail, the temp sensor in the pot will detect a temperature higher than what corresponds to the boiling point of water at 1atm, and open the heating circuit.

Unless you have severely overcooked mental oatmeal in your bone ramekin, you're safe.

Source-

I design kitchen appliances.

Last edited:

Forget to close the drain valves on your conical after draining Star San. Don't do that!

- Joined

- Feb 16, 2012

- Messages

- 4,650

- Reaction score

- 7,077

- Location

- At home, in the brewery in Maryland.

That’s comforting insight. I’m extremely cautious (paranoid) about all forms of pressurized fluids from high pressure tires to unitanks to kitchen devices like pressure cookers. In the Navy we inflated aircraft tires to 300 psi for carrier operations. In the airlines it wasn’t uncommon to see normal pressures above 200 psi. I’ve seen what havoc they can cause when things go south.Ahem,

Actually, the pressure is regulated by a weighted conical pin that fits atop a hollow tube with a small inner diameter. The area of the passage and the mass of the regulator generate ~1 atmosphere of pressure differential before it overcomes the weight, and venting occurs. Should the weight become blocked or jammed, a few additional kpa will cause the silicone cap seal on the end of the float valve, which serves as a burst-disk, to rupture and venting occurs. Should that fail, additional pressure forces the inner pot down onto an overpressure sensor in the base which will open the circuit for the calrod heat element, and pressure will stop rising. It's a variable sensor as well, the mechanism which enables 2 or more pressure settings. Should that sensor fail, the silicone main gasket is forced to vent via fin seal flexure, causing excess pressure to vent around the perimeter of the lid, safely directed downward into the condensate channel. Should all of the above somehow fail, the temp sensor in the pot will detect a temperature higher than what corresponds to the boiling point of water at 1atm, and open the heating circuit.

Unless you have severely overcooked mental oatmeal in your bone ramekin, you're safe.

Source-

I design kitchen appliances.

- Joined

- Nov 26, 2013

- Messages

- 9,924

- Reaction score

- 24,093

severely overcooked mental oatmeal in your bone ramekin

Which, naturally, would be a great name for a rock band.

I have often thought that a RIMS tube could become a bomb. I had a silicone hose for tap water to the plate chiller. I had a 40 psi pressure regulator in the line. For one reason or another, I was working on the system and somehow blocked the flow of tap water out of the plate chiller. The hose "exploded" with a very load bang and water went everywhere. (note to self: Use braided hose).That’s comforting insight. I’m extremely cautious (paranoid) about all forms of pressurized fluids from high pressure tires to unitanks to kitchen devices like pressure cookers. In the Navy we inflated aircraft tires to 300 psi for carrier operations. In the airlines it wasn’t uncommon to see normal pressures above 200 psi. I’ve seen what havoc they can cause when things go south.

Unless you have severely overcooked mental oatmeal in your bone ramekin, you're safe.

Or maybe even three or four.Which, naturally, would be a great name for a rock band.

Yes, learned that lesson one cold night in the garage.I have often thought that a RIMS tube could become a bomb. I had a silicone hose for tap water to the plate chiller. I had a 40 psi pressure regulator in the line. For one reason or another, I was working on the system and somehow blocked the flow of tap water out of the plate chiller. The hose "exploded" with a very load bang and water went everywhere. (note to self: Use braided hose).

Had a length of 3/4 silicone hose connecting the garden hose to IC. I dropped IC into the kettle, turned on spigot outside the garage, and came back in to see a quickly growing swelling in the silicone hose at the IC. I turned back to shut off the spigot but the was a loud 'Pop' and a lot of splashing before I got there.

Don't forget that the 3/8ths coiled copper chiller is going restrict the flow of water and create pressure in the hose. Don't do that...

I share your fear/respect of pressurized fluids. Navy personnel are obviously well acquainted with the dangers of steam, so I'm sure none of this will be news to you, this is for other readers. As a young process engineer, I saw some stuff that opened my eyes. Petrochemical and plastics manufacturing sites have 150# steam as a utility distributed throughout processing plants. Used for 'sparging' (thawing or melting cold spots in piping), it was an everyday necessity in colder months. Sparging lances are elongated metal nozzles enabling operators to inject steam into jacketed lines, penetrating pipe insulation to keep the material flowing. Sometimes fittings fail, hoses burst, valve packings blow out, etc. That steam lance seems like a garden tool in the hand, but a simple slip or mishap can sever a limb. The steam jet is invisible, but it cuts flesh like a welding torch through steel. Steam packs so much heat energy that it instantaneously cauterizes the wound, resulting in a sickening braised pork aroma for the emergency crew.That’s comforting insight. I’m extremely cautious (paranoid) about all forms of pressurized fluids from high pressure tires to unitanks to kitchen devices like pressure cookers. In the Navy we inflated aircraft tires to 300 psi for carrier operations. In the airlines it wasn’t uncommon to see normal pressures above 200 psi. I’ve seen what havoc they can cause when things go south.

I'll never forget that smell.

- Joined

- Feb 16, 2012

- Messages

- 4,650

- Reaction score

- 7,077

- Location

- At home, in the brewery in Maryland.

Quite true. When I first set to sea (55 years ago) the Navy’s predominant steam plants were transitioning from 600 psi to 1,200 psi. In most aircraft hydraulic systems we’re talking 3,000 psi. Scary stuff when you stop to think about encountering a pinhole leak.I share your fear/respect of pressurized fluids. Navy personnel are obviously well acquainted with the dangers of steam, so I'm sure none of this will be news to you, this is for other readers. As a young process engineer, I saw some stuff that opened my eyes. Petrochemical and plastics manufacturing sites have 150# steam as a utility distributed throughout processing plants. Used for 'sparging' (thawing or melting cold spots in piping), it was an everyday necessity in colder months. Sparging lances are elongated metal nozzles enabling operators to inject steam into jacketed lines, penetrating pipe insulation to keep the material flowing. Sometimes fittings fail, hoses burst, valve packings blow out, etc. That steam lance seems like a garden tool in the hand, but a simple slip or mishap can sever a limb. The steam jet is invisible, but it cuts flesh like a welding torch through steel. Steam packs so much heat energy that it instantaneously cauterizes the wound, resulting in a sickening braised pork aroma for the emergency crew.

I'll never forget that smell.

If I haven't said so elsewhere previously, thank you for your service. Now more than ever, our patriots deserve recognition.Quite true. When I first set to sea (55 years ago) the Navy’s predominant steam plants were transitioning from 600 psi to 1,200 psi. In most aircraft hydraulic systems we’re talking 3,000 psi. Scary stuff when you stop to think about encountering a pinhole leak.

Similar threads

- Replies

- 21

- Views

- 1K

- Replies

- 17

- Views

- 2K

- Replies

- 66

- Views

- 3K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)