Thought I'd share a couple of DIY projects that I did shortly after bottling my first batch. The idea was to streamline the process a bit without spending any money.

I grabbed a shoe rack that my wife was about to toss out, cut off the bent portion of the shoe trees, and viola...I had a bottle rack that holds about 55 bottles.

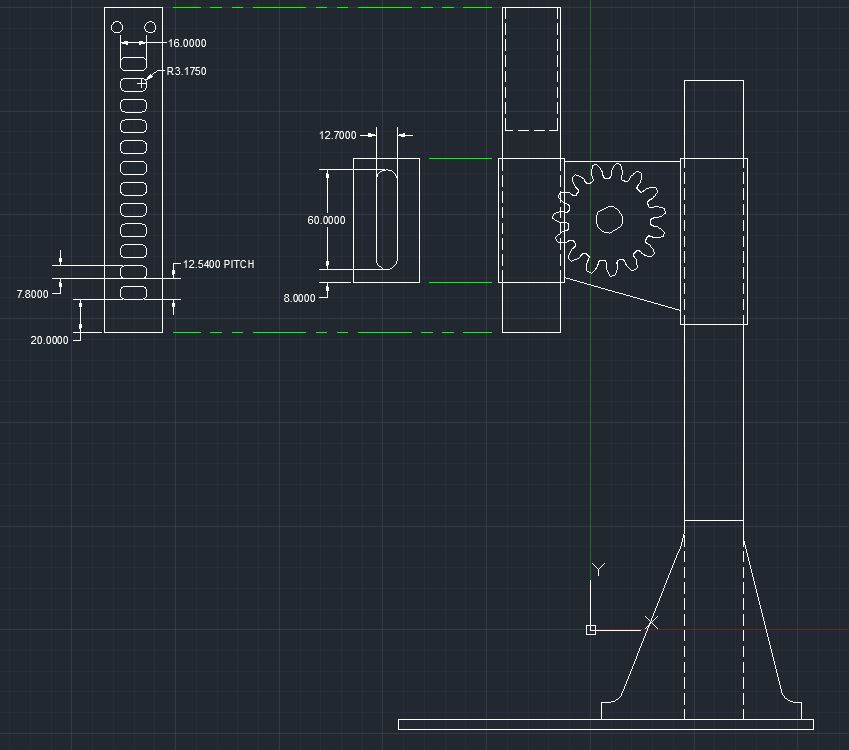

I took the capper bell off of the wing capper that came with my starter kit, then added a rack and pinion press mechanism that I built from some scrap stainless. I spring-loaded the press mechanism to prevent breaking bottles.

Cheers! And let me know if you want any greater detail on either of these.

I grabbed a shoe rack that my wife was about to toss out, cut off the bent portion of the shoe trees, and viola...I had a bottle rack that holds about 55 bottles.

I took the capper bell off of the wing capper that came with my starter kit, then added a rack and pinion press mechanism that I built from some scrap stainless. I spring-loaded the press mechanism to prevent breaking bottles.

Cheers! And let me know if you want any greater detail on either of these.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)