Thanks DayTrippr. I went to HD with my post, off an original Pepsi Cornelius keg, and the 176 doesn't fit. I checked some others parts, and thought I had one, but no luck. That same post fits a new Chinese keg too.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Beer Line Cleaner

- Thread starter geniz

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It's been stated numerous times that the post that fits the (LF)A-176 fitting is a Firestone beer post...

Cheers!

Cheers!

Which is why I haven't found a fitting for my post.

StoutNoDoubt

Well-Known Member

Which is why I haven't found a fitting for my post.

I have posted a video and there is a link along with it for this particular post that you need. 5/8" - 18 threading.

https://youtu.be/zjOPzGw5cuI

I'll give that a try. Thank you Stout.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

BlurryEyed

Well-Known Member

Why don't people just clean their lines when they clean their keg? Just fill keg with cleaning solution and run it through the lines.

Saves C02 and perhaps to just speed the process of swapping out kegs.

Okay, I found answers on pages 39 and 49. With a little trimming of the small plastic tip, a corny post will thread onto the smooth green plastic part of the sprayer. It will require a wrench to cut threads into the smooth plastic with the steel post. Watch that the poppet is pressed in if needed. This is a great solution for someone who has an old post lying around.

SupervisingChildren

Well-Known Member

Since most of these pertain to ball lock posts, any information on what is necessary to make one that works with a pin lock setup?

StoutNoDoubt

Well-Known Member

Since most of these pertain to ball lock posts, any information on what is necessary to make one that works with a pin lock setup?

I would have to assume that you would need to just simply find a post with the same threading and spacing? Not sure if it exists or not but it may.

Thanks for the vid. I'm amused by the dichotomy between the music and the t-shirt. :rockin:Hi, all. I put together a video on building this awesome little beer line cleaner. Check it out below! Cheers!

https://www.youtube.com/watch?v=zjOPzGw5cuI

GenIke

Well-Known Member

Since most of these pertain to ball lock posts, any information on what is necessary to make one that works with a pin lock setup?

I just forced the pin lick post right onto the plastic. The threads on the post cut into the plastic and made corresponding threads in the plastic. No need for a special adapter or anything.

Im sure the same would work for ball locks too.

Huaco

Well-Known Member

I just forced the pin lick post right onto the plastic.

Man... We don't want to know!

StoutNoDoubt

Well-Known Member

Thanks for the vid. I'm amused by the dichotomy between the music and the t-shirt. :rockin:

Lol I dunno what to say...

BlurryEyed

Well-Known Member

BlurryEyed

Well-Known Member

Question - are folks just running 1/2 gal of BLC solution through followed by flushing with water?

I run fresh water through first, then BLC/LLC mix, then water, then beer...

Cheers!

Cheers!

BlurryEyed

Well-Known Member

Is scent free oxi-clean good instead of BLC and if so, what mixture/ratio?

From what I gather oxiclean is not recommended for cleaning draft lines as it isn't as potent as BLC.

BLC is caustic and a more potent cleaner. Previous threads indicate that after using BLC solution on lines formerly cleaned with Oxiclean, a ton of crap came out.

I'd stick with BLC

https://www.homebrewtalk.com/showthread.php?t=44471

Hey All...newbie that decided to join to learn from more experienced Home Brewers....

I am trying to follow the thread to make my own cleaning kit and have a 1 gallon pump sprayer at home that I purchased specifically to make this rig. I am having a difficult time trying to figure out what exactly I need because I do not have the ball lock or whatever on my beer line hose. My beer line hose has a threaded nut (that I believe is 7/8) that goes directly in my coupler? Here is a link of what my setup consists of:

Beer line:

http://www.amazon.com/dp/B004SKXW12/?tag=skimlinks_replacement-20

End of beer line attaches directly to keg coupler:

http://www.amazon.com/dp/B00HSI8JP0/?tag=skimlinks_replacement-20

I apologize up front for the novice questions but I really would like to get a cleaning system set up versus taking every piece apart.

Thanks for any assistance you can provide....

I am trying to follow the thread to make my own cleaning kit and have a 1 gallon pump sprayer at home that I purchased specifically to make this rig. I am having a difficult time trying to figure out what exactly I need because I do not have the ball lock or whatever on my beer line hose. My beer line hose has a threaded nut (that I believe is 7/8) that goes directly in my coupler? Here is a link of what my setup consists of:

Beer line:

http://www.amazon.com/dp/B004SKXW12/?tag=skimlinks_replacement-20

End of beer line attaches directly to keg coupler:

http://www.amazon.com/dp/B00HSI8JP0/?tag=skimlinks_replacement-20

I apologize up front for the novice questions but I really would like to get a cleaning system set up versus taking every piece apart.

Thanks for any assistance you can provide....

Last edited by a moderator:

Hey All...newbie that decided to join to learn from more experienced Home Brewers....

I am trying to follow the thread to make my own cleaning kit and have a 1 gallon pump sprayer at home that I purchased specifically to make this rig. I am having a difficult time trying to figure out what exactly I need because I do not have the ball lock or whatever on my beer line hose. My beer line hose has a threaded nut (that I believe is 7/8) that goes directly in my coupler? Here is a link of what my setup consists of:

Beer line:

http://www.amazon.com/dp/B004SKXW12/?tag=skimlinks_replacement-20

End of beer line attaches directly to keg coupler:

http://www.amazon.com/dp/B00HSI8JP0/?tag=skimlinks_replacement-20

I apologize up front for the novice questions but I really would like to get a cleaning system set up versus taking every piece apart.

Thanks for any assistance you can provide....

What I found that fit that nut was a pressure washer quick disconnect in the big box stores

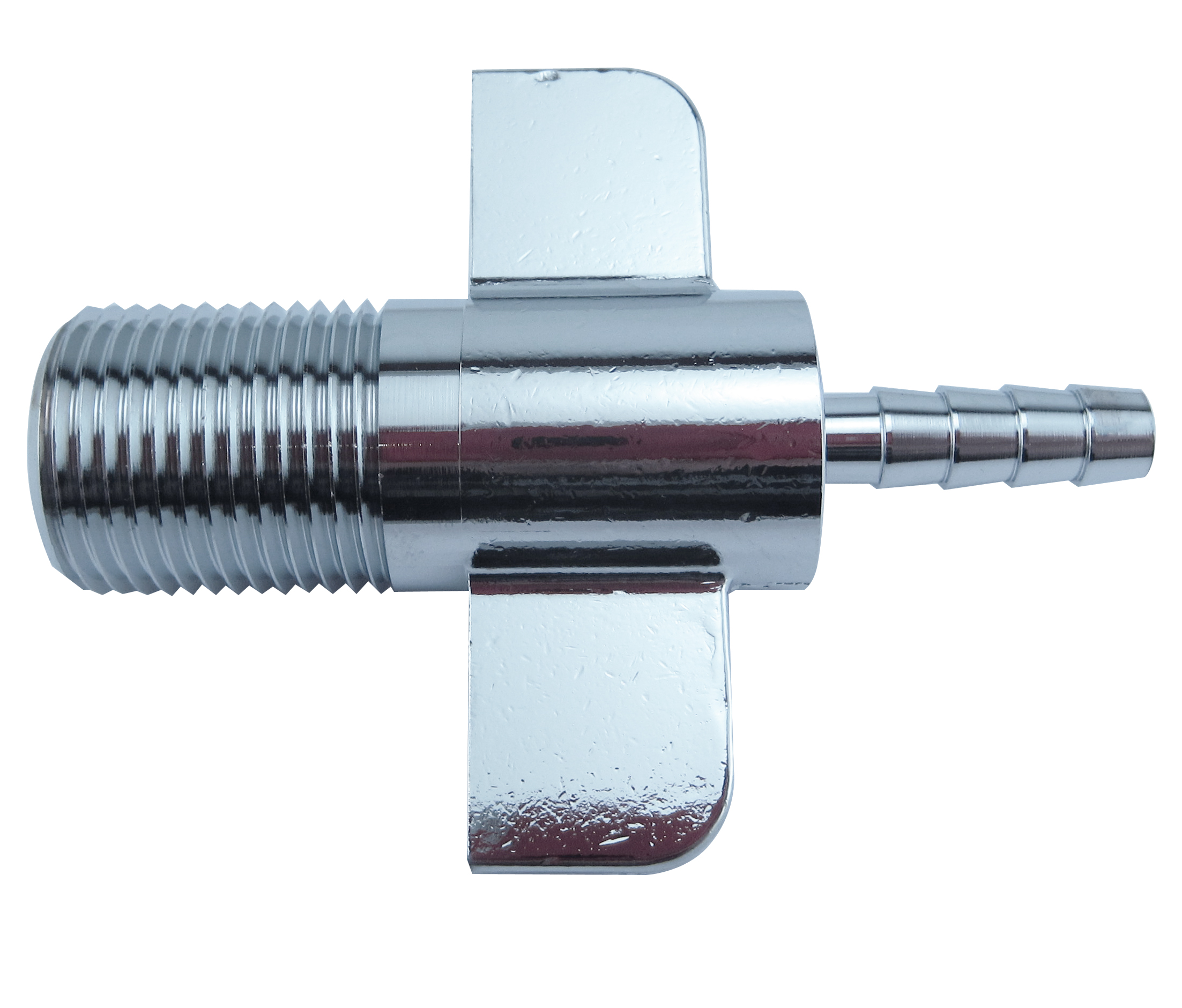

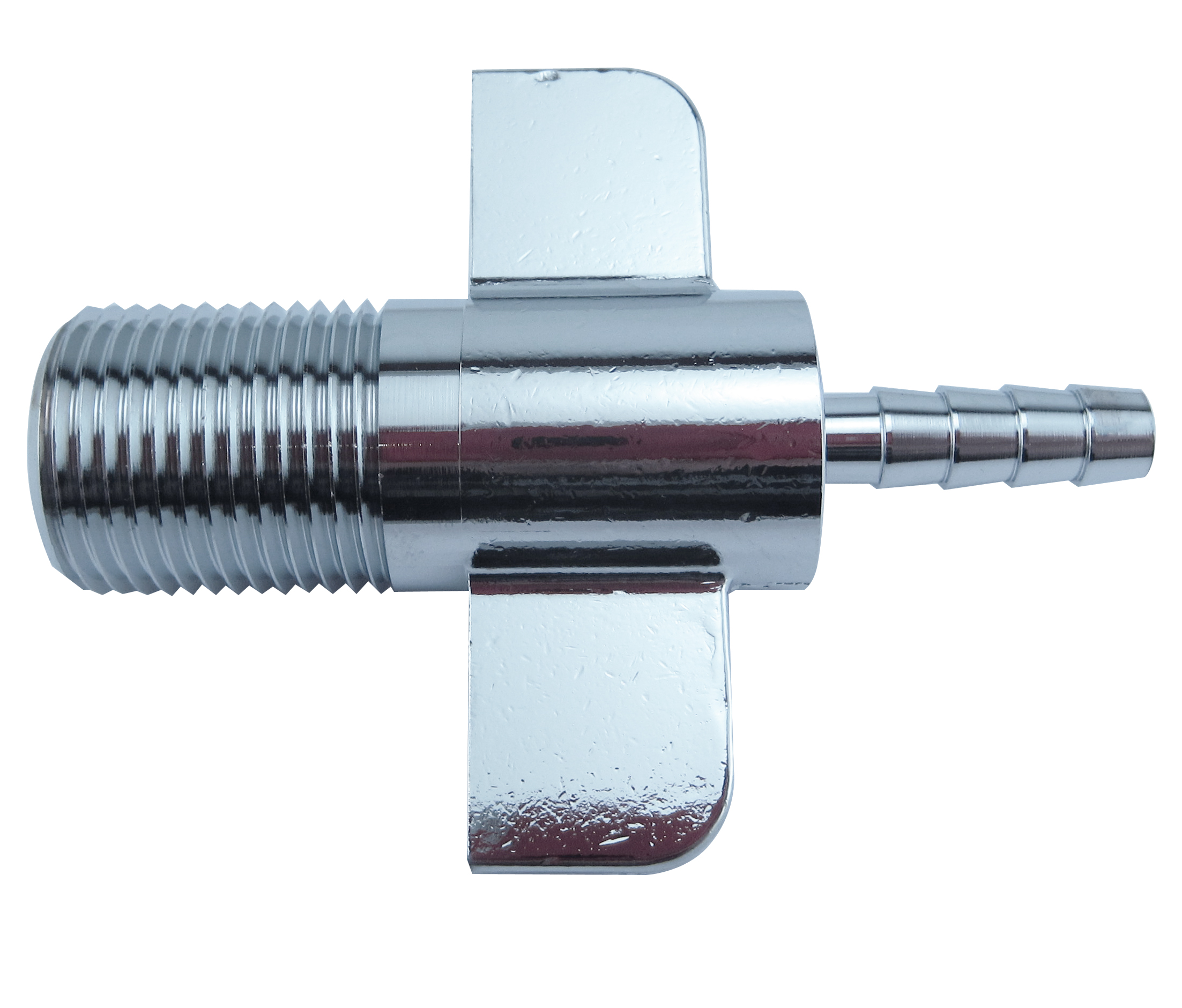

View attachment 1459786229317.jpg

Last edited by a moderator:

What I found that fit that nut was a pressure washer quick disconnect in the big box stores

Thanks for the response....

Any reason why a barbed end would not work like this:

I also found the 3/8 quick disconnect like you were talking about but the quick disconnect plus the other end to fit on the beer line would be like 8.50 plus 4.00 bucks or something where the barbed end by itself would only cost about 3.50?

Also what size tubing did you use between the brass fitting and the sprayer....the tubing in the pic that I found worked decent (although it was kind of hard to push on the sprayer end) was 1/2 OD and 3/8 ID.

Thanks again for the assistance!

I could not find one in stores local to me that had the same thread as the nut from the beer coupler. There were a couple that were close but if I felt it was too loose or I was forcing it on I felt it would end up leaking. I had the benefit of having a couple of those nuts from the coupler with me from my kegerator build when I cut them off the lines. I knew my inability to throw anything away would come in handy some day.

I also found the 3/8 quick disconnect like you were talking about but the quick disconnect plus the other end to fit on the beer line would be like 8.50 plus 4.00 bucks or something where the barbed end by itself would only cost about 3.50?

Ah just realized the one I took the picture of was the one I was experimenting with the female disconnect. Hence why that one has the quick disconnect to female thread and then a male to male adapter. I thought having the quick disconnect might come in handy but turned out to be more expensive and believe it didn't work as well also. I was building 2 and ended up leaving one of that way since I already had the parts. The other one I built I got it down to 1 adapter. I'll put a list of what I bought in the end and what I would go with if I was building another one.

Also what size tubing did you use between the brass fitting and the sprayer....the tubing in the pic that I found worked decent (although it was kind of hard to push on the sprayer end) was 1/2 OD and 3/8 ID.

Thanks again for the assistance!

These are the parts I bought to build this. I tend to go to Lowes so thats where these are from. your picture looks like it's at HD but I'm sure you can find something similar there

2 gallon Plastic Sprayer Item#303427 $15.97

http://www.lowes.com/pd_303427-78071-16200MP___?Ntt=303427&UserSearch=303427&productId=1000004564

Male Quick Disconnect Plug x Male Metric (M22 I believe) Item#210556 $4.98

http://www.lowes.com/ProductDisplay...mber=210556-60455-SGY-PWA26&storeId=10151&N=0

2x 1/4in-5/8in Hose Clamps Item#92897 $0.68

http://www.lowes.com/ProductDisplay...rtNumber=92897-33599-CL4PK2&storeId=10151&N=0

1.5 ft - 5/8" OD 1/2" ID Tubing Item#652379 $0.90

http://www.lowes.com/ProductDisplay...Number=652379-71925-7006PNL&storeId=10151&N=0

2x 5/16inx3/4in Neoprene Fender Washer Item#136598 $0.92

http://www.lowes.com/ProductDisplay...tNumber=136598-37672-880370&storeId=10151&N=0

So total comes to $23.45+tax

I found there was too much play between nut and coupler so I put two of those neoprene washers in the nut on the beer lines to remove that play and make sure nut sealed to the line. Worked well and didn't leak, just have to make sure you have a few of them on hand in case they get lost and took them out before reattaching to the coupler.

Here is the whole assembly:

Mods hope posting all the links is not an issue if it is let me know and I can remove them.

Last edited:

eba3317-

Thanks for all the information...including the prices / links of the actual stuff you bought that def will make it easier if only.....

I did not hit another bump in the road...I figured I would double check my connections on my kegerator this morning and the hose line does not attach to the coupler like I originally thought (with the screw on nut). My connection has a barbed end that the hose line goes down over with a hose clamp? Now I am really confused on what I need to do...the screw on nut goes to the CO2 tank.

Do I need to get a different coupler to make all this work...? Any thoughts from anyone out there?

Thanks for all the information...including the prices / links of the actual stuff you bought that def will make it easier if only.....

I did not hit another bump in the road...I figured I would double check my connections on my kegerator this morning and the hose line does not attach to the coupler like I originally thought (with the screw on nut). My connection has a barbed end that the hose line goes down over with a hose clamp? Now I am really confused on what I need to do...the screw on nut goes to the CO2 tank.

Do I need to get a different coupler to make all this work...? Any thoughts from anyone out there?

That wing nut is the same connector as the CO2 line. The same solution applies.

That wing nut is the same connector as the CO2 line. The same solution applies.

Thanks for the feedback...I def know that the barbed end unscrews from the top handle because I have take it apart to clean and replace a washer I believe. If that is the case than I think I just need to get a female adapter for the barbed end.

I wasn't sure if that entire top handle piece was supposed to unscrew from the top of the coupler or not. I could have swore I have tried to unscrew it before but it just turns and turns to no avail

You'd use the same male adapter, screw the wing nut onto that, and pump your solution through. Unles I'm missing your question?

You'd use the same male adapter, screw the wing nut onto that, and pump your solution through. Unles I'm missing your question?

LBussy-

First let me thank you for your patience...as you can see I am a complete novice when it comes to this but def trying.

What I am trying to ask is...do I just unscrew the "barbed" fitting where the beer line goes in (red arrow) or do I try to unscrew the entire T-handle fitting from the top of the coupler (black arrows)? Hope the pic makes sense...

The wing-nut (t-handle or black arrows) holds the barb fitting against the tap itself. So when you remove that you will have the barb fitting still sort of inside the wingnut. Then you screw the wing-nut (with a washer or two) against the male fitting shown above on the cleaning setup. The wing nut will clamp the barb fitting (basically a flat face) against the male adapter up there (another flat face) with a washer in between.

Once you take it apart (untap the keg first and relieve the pressure) you will see exactly what I mean. It's the same fitting as the red CO2 line, just easier to unscrew.

The brass fitting that @eba3317 shows up there looks as if it will work. If you really want a purpose-built one, here's one from Beveragefactory:

Either one will allow you to remove the wingnut from your keg coupler and attach it to your cleaning line.

Once you take it apart (untap the keg first and relieve the pressure) you will see exactly what I mean. It's the same fitting as the red CO2 line, just easier to unscrew.

The brass fitting that @eba3317 shows up there looks as if it will work. If you really want a purpose-built one, here's one from Beveragefactory:

Either one will allow you to remove the wingnut from your keg coupler and attach it to your cleaning line.

The wing-nut (t-handle or black arrows) holds the barb fitting against the tap itself. So when you remove that you will have the barb fitting still sort of inside the wingnut. Then you screw the wing-nut (with a washer or two) against the male fitting shown above on the cleaning setup. The wing nut will clamp the barb fitting (basically a flat face) against the male adapter up there (another flat face) with a washer in between.

Once you take it apart (untap the keg first and relieve the pressure) you will see exactly what I mean. It's the same fitting as the red CO2 line, just easier to unscrew.

The brass fitting that @eba3317 shows up there looks as if it will work. If you really want a purpose-built one, here's one from Beveragefactory:

Either one will allow you to remove the wingnut from your keg coupler and attach it to your cleaning line.

LBussy-

That def clears it up and thanks for breaking that down...appreciate it! Now I understand the entire wing nut "should" come off the top of the coupler and contain the barb still screwed inside.

My only question is if I unscrew the wing nut from the top of the coupler that will be a "female" end in which I would screw a "male" brass fitting as the one that eba3317 suggested correct?

http://cdn.homebrewtalk.com/attachment.php?attachmentid=348813&stc=1&d=1459786231

or possibly the one I found yesterday at HD:

http://s431.photobucket.com/user/michael-dd/media/20160404_125852_zps6e9gs7ha.jpg.html

Thanks again!

Similar threads

- Replies

- 13

- Views

- 628

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)