That looks sweet beerthirty. Looks like a big-block.

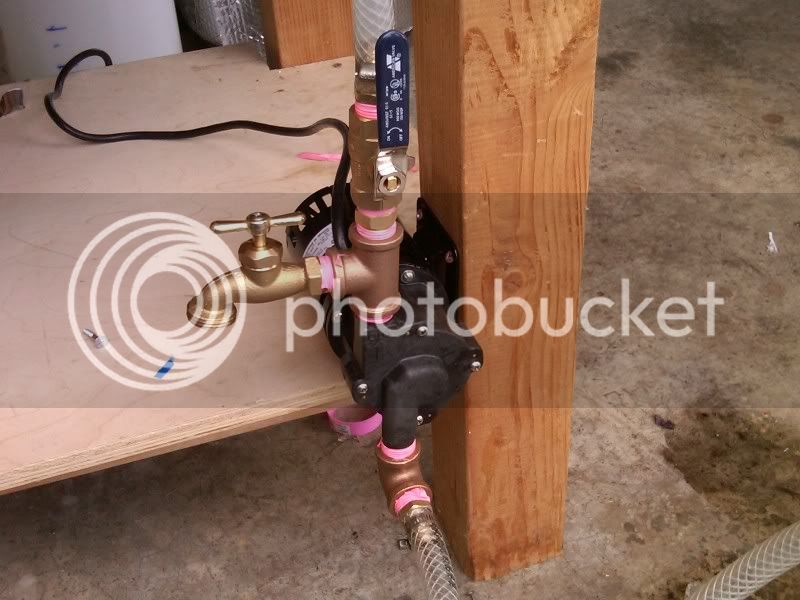

Those aren't technically vacuum breakers. I mentioned these degassing valves

in post 22 of this thread. A vacuum breaker works such that if you put one on the suction side of the pump it would open and your pump would just keep pulling air through the vacuum breaker. A vacuum breaker prevents you from pulling vacuum...but seals with positive pressure.

EDIT: Vacuum breakers prevent stuff like this from happening:

YouTube - Tank car implosion d'un wagon citerne

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)