underdog378

Well-Known Member

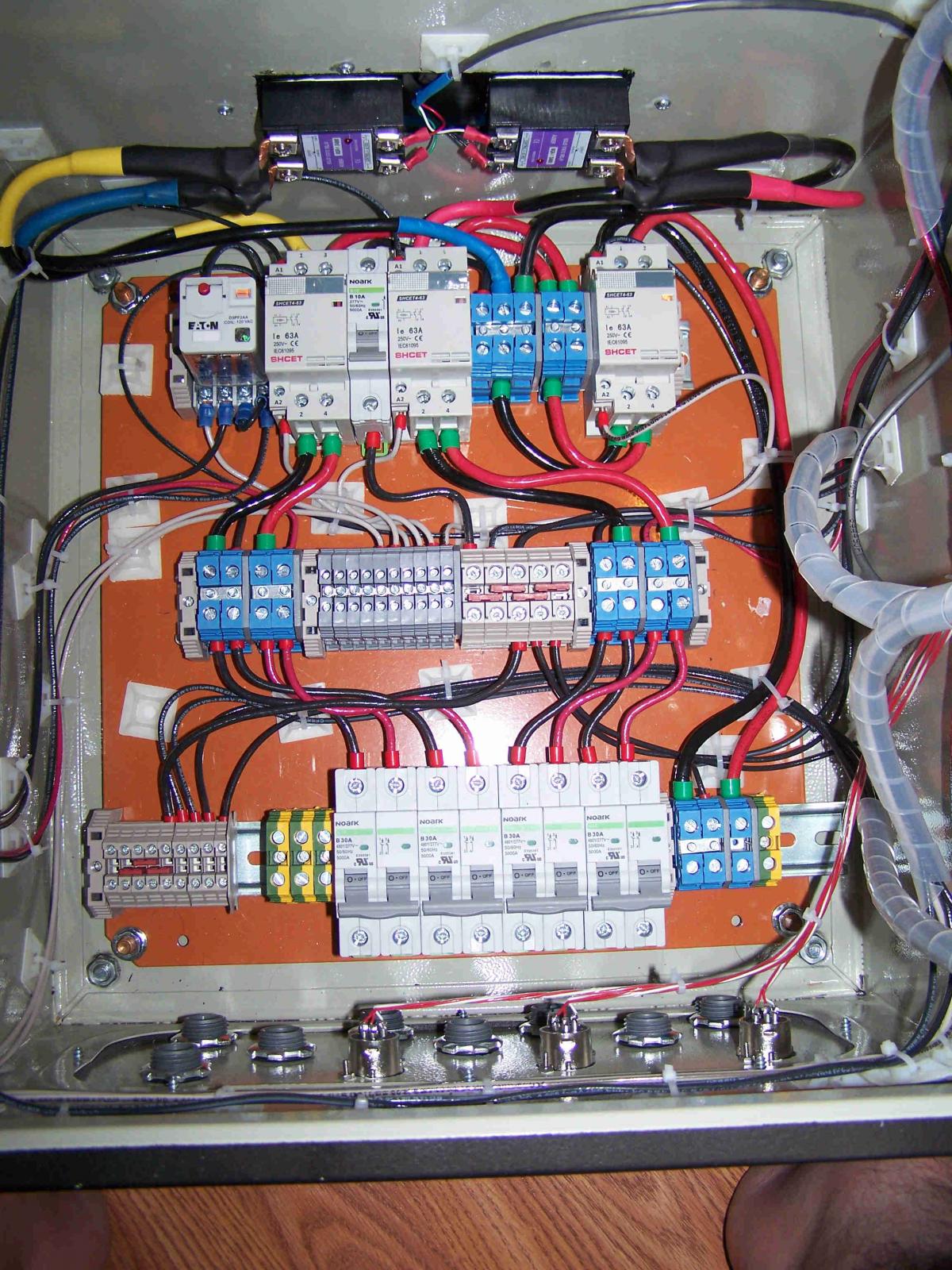

I'm currently in the process of building a control panel for a 20A 120v RIMS system. I have the wiring diagram part figured out, but am having some issues with the actual wiring itself.

The door panel was fine, I used crimp spade terminals for the connections there. The inner panel I went with a DIN rail with DIN mounted terminal blocks and DIN mounted contactors. I bought the terminal block kit from Auber ( http://www.auberins.com/index.php?main_page=product_info&cPath=46&products_id=445 ).

My problem is with the ferrules. I don't have a ferrule crimper, and my regular wire crimpers are useless for a ferrule. I'm using stranded wire (12 gauge main power in, 14 gauge everything else, fused).

Going through other control panel builds I've seen on the forums, I haven't found any other pictures of people using ferrules at all, they all appear to be tightening down on bare wire.

Is tightening on the bare wire ok? Or do I need to go buy a ferrule crimper to do it the right way. Like I said, the reason I ask is because the control panel builds I see (including ebrewsupply) don't seem to be using any ferrules.

Thanks, and I'm going to post a new thread once I get this build all finished up!

The door panel was fine, I used crimp spade terminals for the connections there. The inner panel I went with a DIN rail with DIN mounted terminal blocks and DIN mounted contactors. I bought the terminal block kit from Auber ( http://www.auberins.com/index.php?main_page=product_info&cPath=46&products_id=445 ).

My problem is with the ferrules. I don't have a ferrule crimper, and my regular wire crimpers are useless for a ferrule. I'm using stranded wire (12 gauge main power in, 14 gauge everything else, fused).

Going through other control panel builds I've seen on the forums, I haven't found any other pictures of people using ferrules at all, they all appear to be tightening down on bare wire.

Is tightening on the bare wire ok? Or do I need to go buy a ferrule crimper to do it the right way. Like I said, the reason I ask is because the control panel builds I see (including ebrewsupply) don't seem to be using any ferrules.

Thanks, and I'm going to post a new thread once I get this build all finished up!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)