How will you recirculate your mash? Also, are you doing no-sparge?

Recirculating from BK to MT and back using pumps and valves. Correct No Sparge.

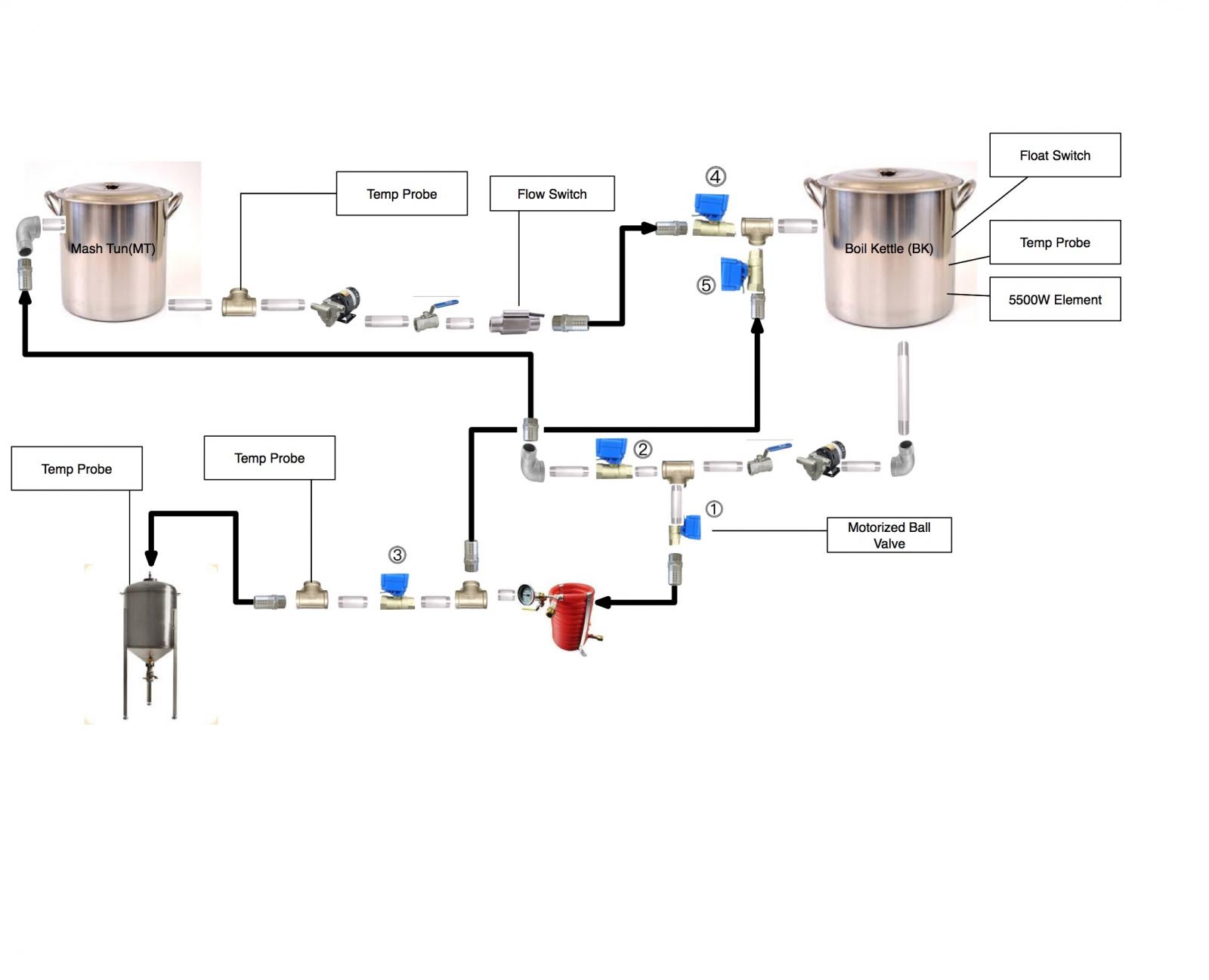

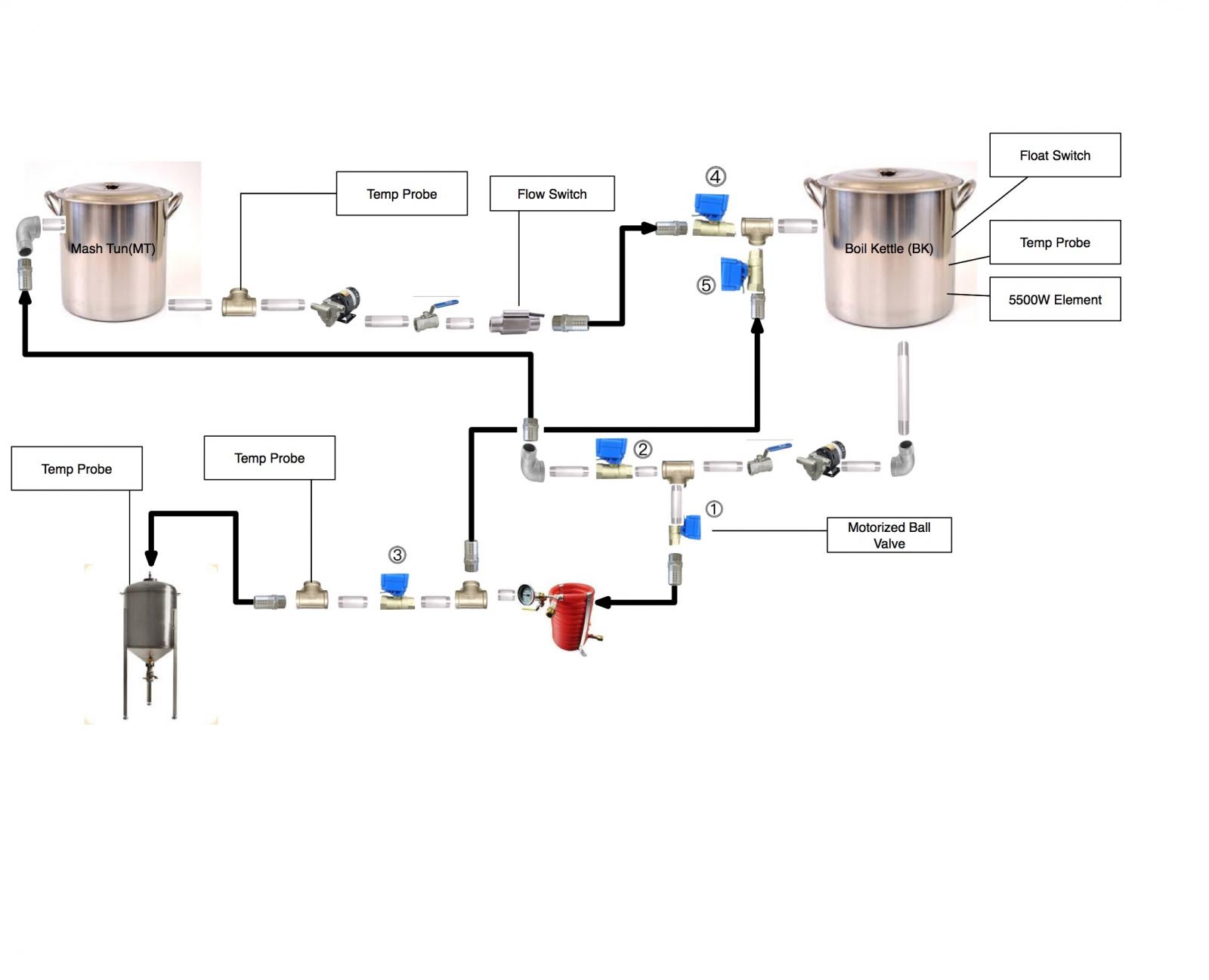

I have outlined the process flows here:

Heat Strike Water

1. All Automatic valves are closed

2. Strike water heated in BK to correct temp

3. Open Automatic valve 2

4. Pump by BK is turned on

a. Water is pumped to Mash Tun where grains are placed in COFI Filter

b. Brew kettle contains a float to control automatic valve 1 (open/close) and heating element to ensure the water level stays above the heating element

c. (Manual Process) adjust the manual valve behind the pumps to control flow

5. Wait for Mash Tun to partially fill

6. Once Mash Tun is partially filled

a. Automatic Valve 4 is opened on sufficient level in Mash Tun

b. Pump on Mash Tun output is turned on

c. Wort is pumped back into BK

d. Monitor and adjust the manual valves to ensure correct flow of wort back into BK

7. Once mash time has elapsed

a. Close automatic valve 2

b. Turn off pump on output side of BK

c. Pump wort in Mash Tun back into BK using pump on output of Mash Tun

d. Flow switch monitors wort from Mash Tun and shuts off pump as needed, once flow stops shut off pump on output of Mash Tun

e. Continue to monitor flow from flow switch and turn back on pump by Mash Tun as needed

f. Close automatic valve 4

g. Turn of pump by Mash Tun

8. Bring BK to boil and add hops as required

9. 10 minutes prior to end of boil

a. Open automatic valves 1 and 5

b. Turn on pump by BK

c. Pump wort through counter flow chiller to sanitize and pump back into BK

d. Once boil time has elapsed turn off BK pump and close automatic valve 5 and open automatic valve 3

e. Adjust flow on manual valve on Chiller to hit ferment temperature

f. Monitor temp probe behind Chiller for the ferment temp (68-72F)

i. Open automatic valve 3 and close automatic valve 5

g. Pump wort into Fermenter

h. Once BK is empty shut off pump behind BK and close all valves

Think I covered all the bases. I do see a challenge though:

1) Ensuring element remains submerge, have been doing 5 gallon batches in 15 gallon kettles, so about 7 gallons water initially. I am not sure if thats enough water to cover the element and ensure enough for the hoses and MT.