Ok, that didn't really work for me. To be honest, much of the discussion in this thread is a bit beyond me but I am trying to learn. So...here is what I have be able to do so far...

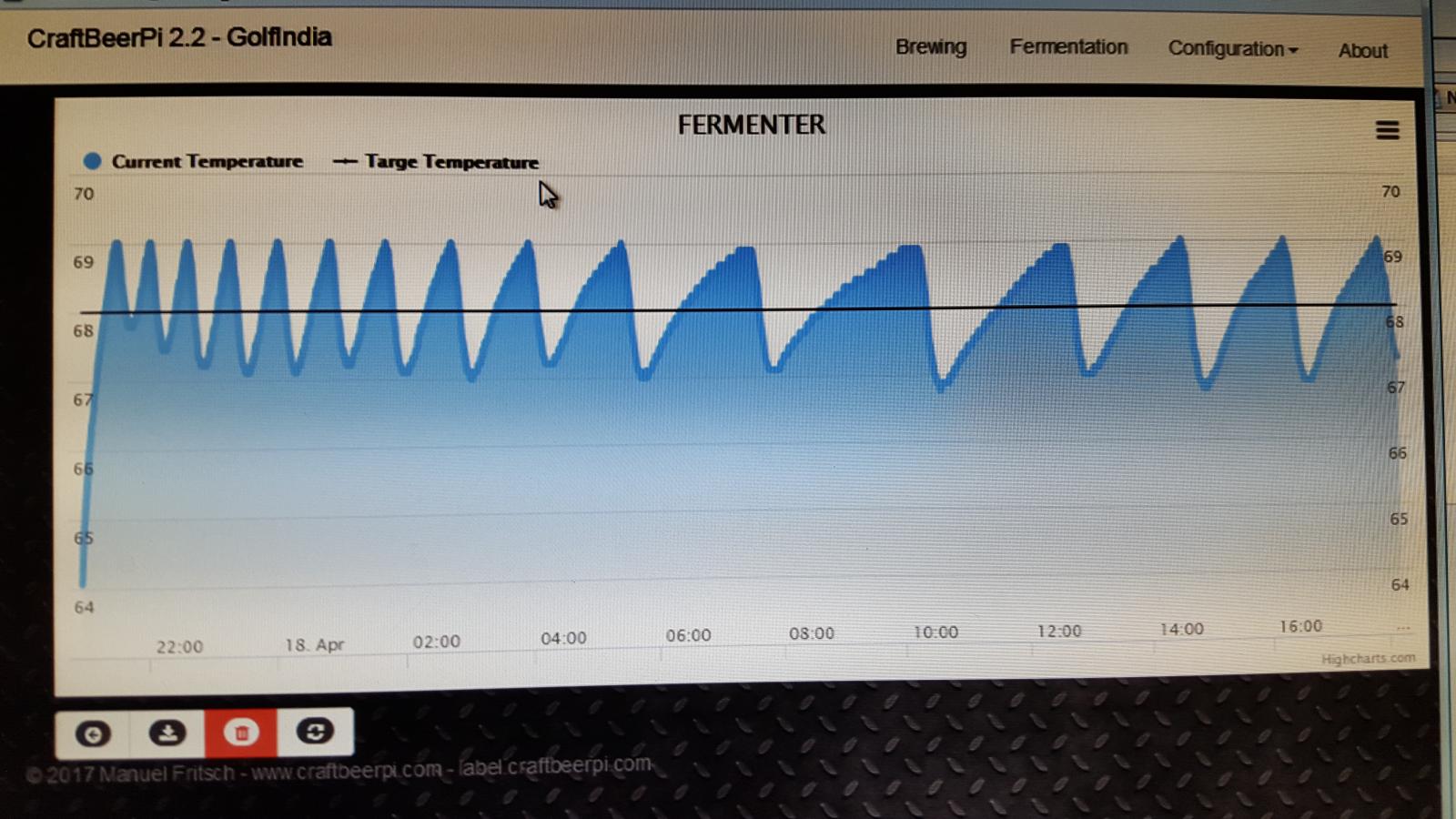

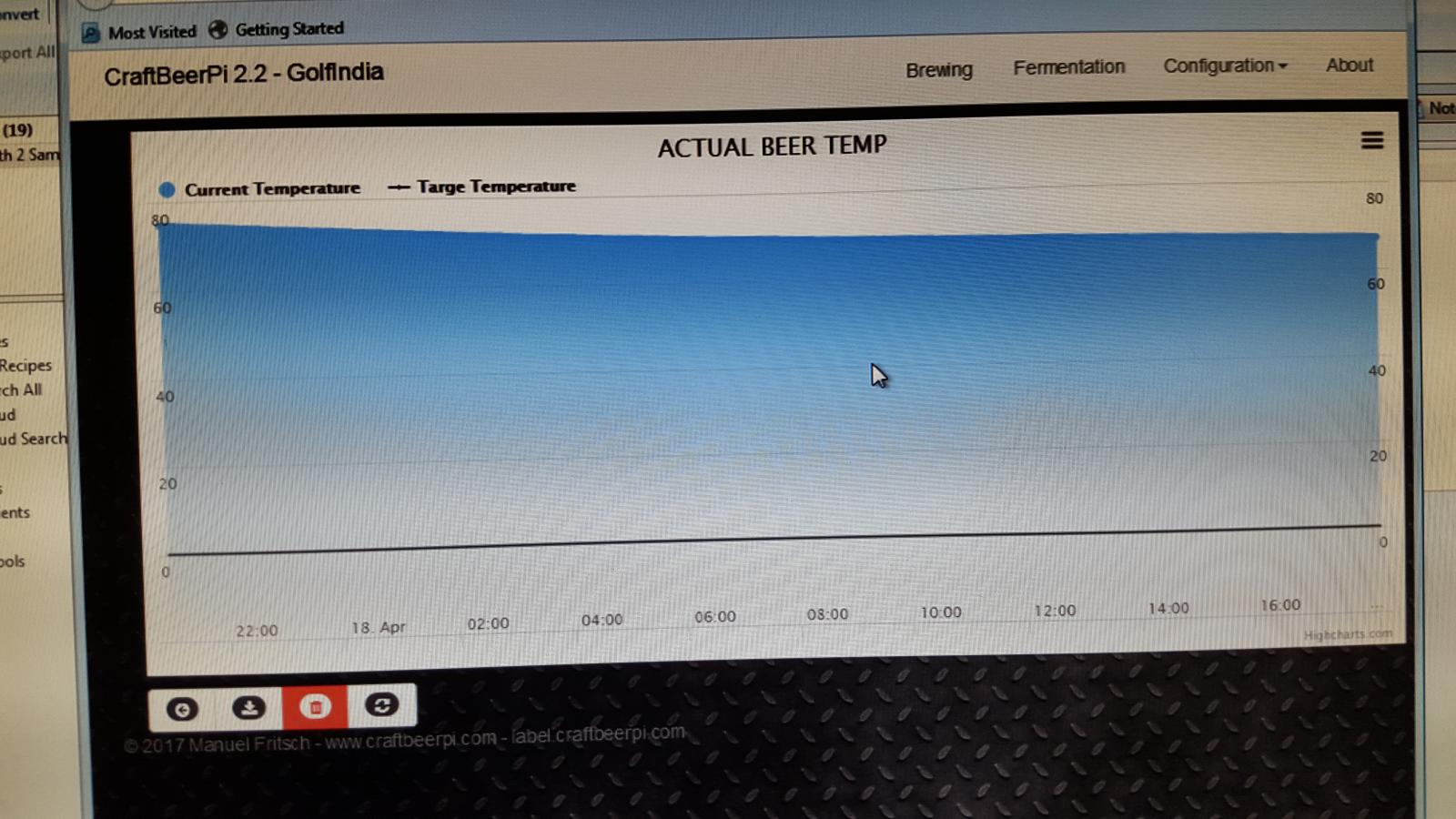

Install CarftbeerPi on RaspPi, no problem. Hooked up 3 DS18B20 sensons to the pi using a breadboard and 4k7 resistor and got CBP to read them, no problem. Hooked up a 5v relay board to the RaspPi and was able to trigger the relays after setting them up in CBP, no problem.

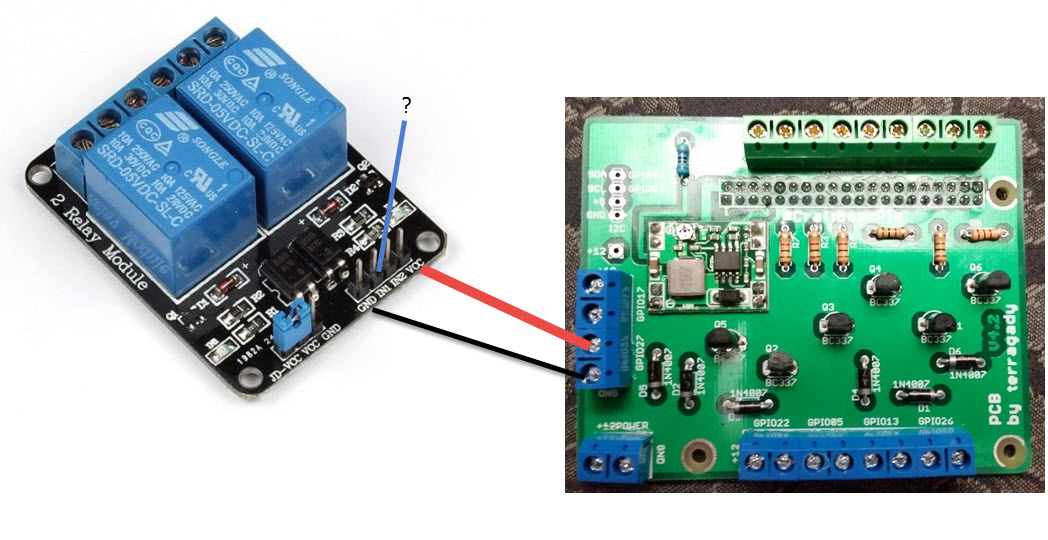

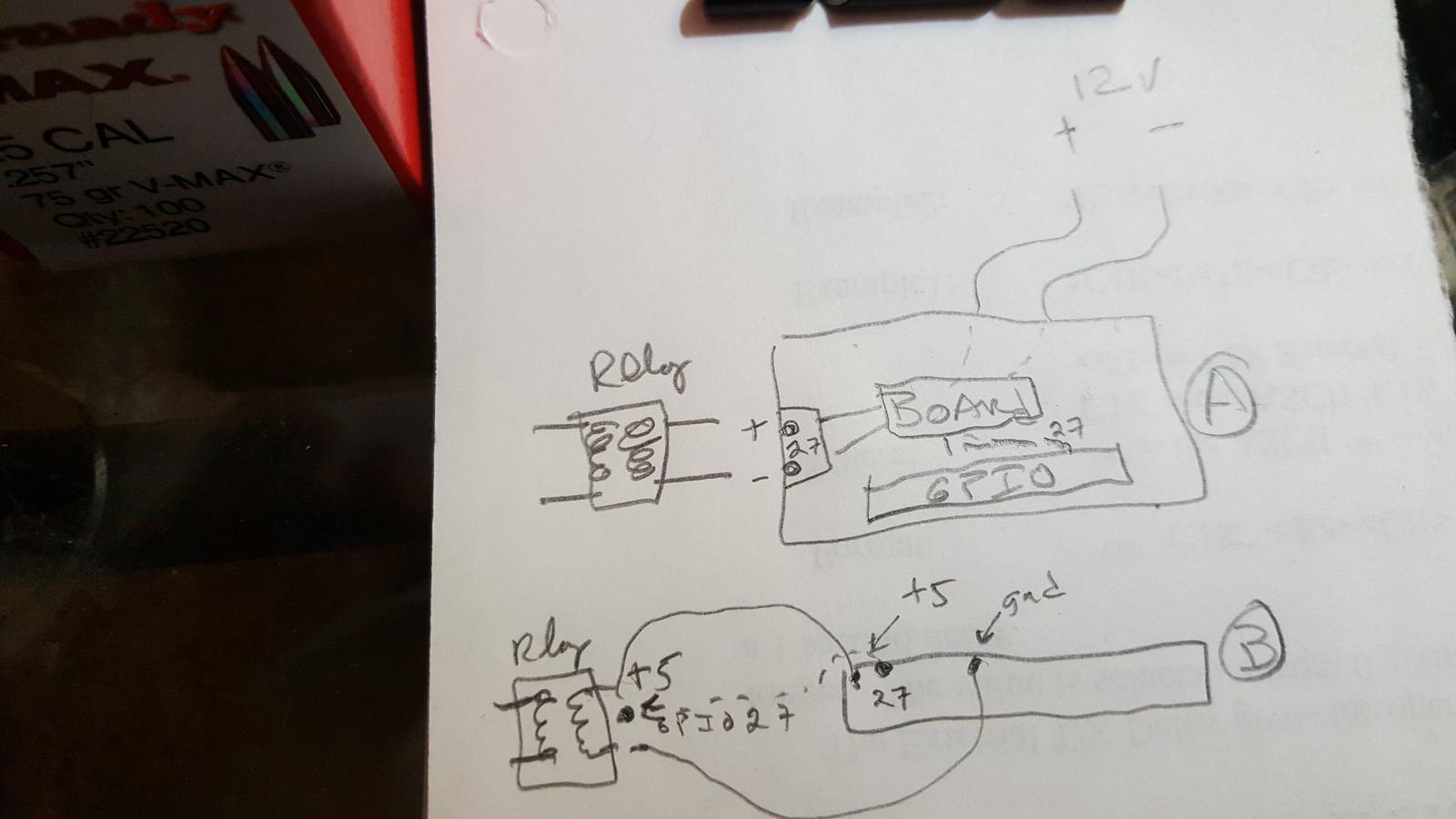

Then, read about the terragady board and thought it would be awesome to have screw in terminals and a built in resistor for the DS18B20's so bought the board. Terragady board works and no problem with the DS18B20's, CBP reads them just fine. My problem is getting a relay board to work using the terragady. Each output (GPIO) on the terragady is +12 and gnd. GPIO's on the RaspPI are 3.3v and if I understand correctly, all the grounds on the RaspPi are common so not sure why there is a ground for each output (GPIO) on the trerragady.

Also, since the outputs are 12v, I assumed that the 5v relay board would not work so I bought a 12v relay board. Can't seem to get that to work. I have powered the realy board with +12 but all my reading has suggested that the logic pin voltage on either board needs to be 5v. If that is true, then I guess I can't use the boards? I realize that I could by SSR's (Need at least one for RIMS tube element anyway) to run the pumps but that seems overkill and I already have the two relay boards.

Any thoughts/help?

Thanks

Dave

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)