You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CraftBeerPi - Raspberry Pi Software

- Thread starter chixxi

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I currently use an SSVR w/ a potentiometer (electric) to control my boil.

Is there a similar solution that can be integrated w/ CraftBeerPi?

Has anyone ran into any issues w/ boil overs due to the indirect "push button" approach of this setup (rather then a direct turn dial to decrease power to the heating element)?

Is there a similar solution that can be integrated w/ CraftBeerPi?

Has anyone ran into any issues w/ boil overs due to the indirect "push button" approach of this setup (rather then a direct turn dial to decrease power to the heating element)?

hairybiker

Member

- Joined

- Feb 17, 2017

- Messages

- 8

- Reaction score

- 5

Quick Q on setup, when using a 3.1(nope 4.2) board what setup option (GPIO etc) do you choose, it wasn't clear on the setup screens.

Finally got round to assembling the board and plugging in my new pi zero w on to it (was swearing when I powered up and no led on the zero, needed a newer raspberrian image)

Finally got round to assembling the board and plugging in my new pi zero w on to it (was swearing when I powered up and no led on the zero, needed a newer raspberrian image)

Last edited:

toadyus

Well-Known Member

Quick Q on setup, when using a 3.1 board what setup option (GPIO etc) do you choose, it wasn't clear on the setup screens.

Finally got round to assembling the board and plugging in my new pi zero w on to it (was swearing when I powered up and no led on the zero, needed a newer raspberrian image)

You answered your own question, you want to select GPIO.

hairybiker

Member

- Joined

- Feb 17, 2017

- Messages

- 8

- Reaction score

- 5

There was several options for GPIO that was what confused me.

toadyus

Well-Known Member

Sorry but how many types of boards do we have here?

There are many different types of boards available, you just need to pick one that is going to suit your needs.

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

So what is the difference between the 3 versions of your boards?There are many different types of boards available, you just need to pick one that is going to suit your needs.

hairybiker

Member

- Joined

- Feb 17, 2017

- Messages

- 8

- Reaction score

- 5

The number of outputs really. If you only need 2 (heat/pump) then the smallest board will work fine, whereas it you need multiple pumps/heaters then get one of the bigger boards.

I got the 4.1 but the 5 (not available when I got the other one) would have been better for my Grainfather setup. But the pi-zero sits nicely on top of the board.

I got the 4.1 but the 5 (not available when I got the other one) would have been better for my Grainfather setup. But the pi-zero sits nicely on top of the board.

Bigdaddyale

Well-Known Member

Did you have any problems setting up the temp. sensors with 4.1? I thnk you had to change the gpio around.The number of outputs really. If you only need 2 (heat/pump) then the smallest board will work fine, whereas it you need multiple pumps/heaters then get one of the bigger boards.

I got the 4.1 but the 5 (not available when I got the other one) would have been better for my Grainfather setup. But the pi-zero sits nicely on top of the board.

Terragady didn't release the Gerber files on 5.

toadyus

Well-Known Member

The number of outputs really. If you only need 2 (heat/pump) then the smallest board will work fine, whereas it you need multiple pumps/heaters then get one of the bigger boards.

I got the 4.1 but the 5 (not available when I got the other one) would have been better for my Grainfather setup. But the pi-zero sits nicely on top of the board.

If I'm not mistaken you have a 4.2 board not a 4.1...I never had any 4.1 boards made and yes you're correct each board has a set # of outputs.

3.1 has 5 outputs

4.2 has 6 outputs

5.0 has 8 outputs

For more information on each board you can check out our website. Thanks

hairybiker

Member

- Joined

- Feb 17, 2017

- Messages

- 8

- Reaction score

- 5

I haven't got around to actually connecting anything to the pcb yet  Just assembled and put the zero on top to test it.

Just assembled and put the zero on top to test it.

Yet it is 4.2 my mistake memory not what it was.

More outputs than I need but room for expansion.

Yet it is 4.2 my mistake memory not what it was.

More outputs than I need but room for expansion.

Having a problem with my 5.0 terragady board. It causes my RPi 3 to go into a boot cycle loop. I get the Pixel screen, the rainbow screen, the 5 raspberries and then it cycles through that over and over. If I unhook the board, the Pi boots up fine.

Anyone have any ideas??

Dave

Anyone have any ideas??

Dave

toadyus

Well-Known Member

Having a problem with my 5.0 terragady board. It causes my RPi 3 to go into a boot cycle loop. I get the Pixel screen, the rainbow screen, the 5 raspberries and then it cycles through that over and over. If I unhook the board, the Pi boots up fine.

Anyone have any ideas??

Dave

Are you trying to power both at the same time?

Are you trying to power both at the same time?

Nope. Only 12v power into terragady board.

I currently use an SSVR w/ a potentiometer (electric) to control my boil.

Is there a similar solution that can be integrated w/ CraftBeerPi?

Has anyone ran into any issues w/ boil overs due to the indirect "push button" approach of this setup (rather then a direct turn dial to decrease power to the heating element)?

Has no one had this issue?

mwawrzyniec

Active Member

- Joined

- Oct 8, 2015

- Messages

- 32

- Reaction score

- 2

What's the web address for the information on the different boards?

And has anyone done any work on connecting the sensors/SSR wirelessly?

And has anyone done any work on connecting the sensors/SSR wirelessly?

toadyus

Well-Known Member

What's the web address for the information on the different boards?

And has anyone done any work on connecting the sensors/SSR wirelessly?

The website is in my signature below, any questions please pm me.

Only thing that I've used wireless is to connect the pi to my network...sorry.

adrianoftyriel

Active Member

- Joined

- Jan 23, 2016

- Messages

- 34

- Reaction score

- 6

Trying to install on a freshly flashed chip, and I get this error right before gembird support:

Any ideas?

Command "/usr/bin/python -u -c "import setuptools, tokenize;__file__='/tmp/pip-build-Ax5KCY/greenlet/setup.py';f=getattr(tokenize, 'open', open)(__file__);code=f.read().replace('\r\n', '\n');f.close();exec(compile(code, __file__, 'exec'))" install --record /tmp/pip-LTDCnA-record/install-record.txt --single-version-externally-managed --compile" failed with error code 1 in /tmp/pip-build-Ax5KCY/greenlet/

Any ideas?

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

I have the official craftbeerpi board. I am trying to set up the built-in buzzer. Does anyone know what gpio the software needs to be set to?

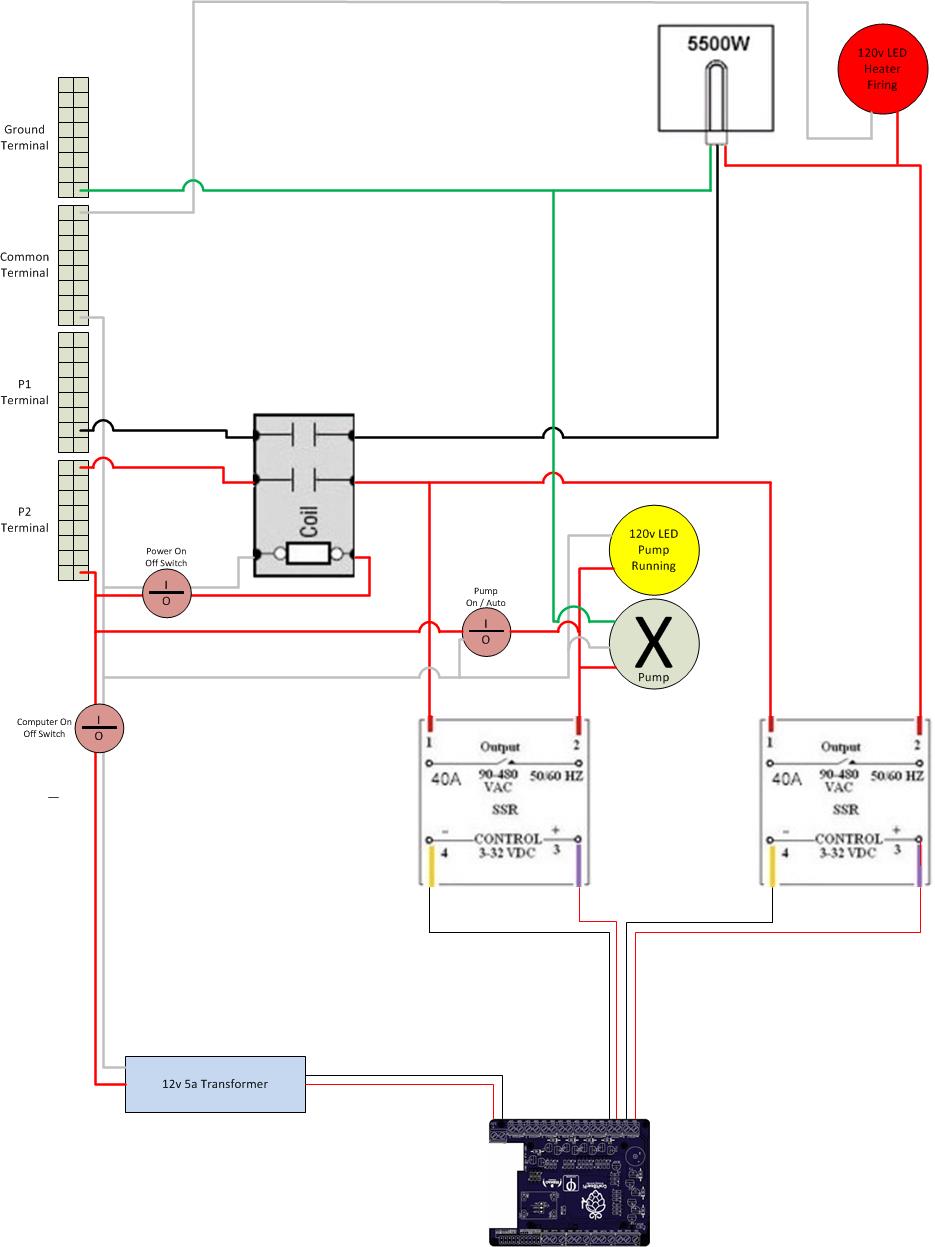

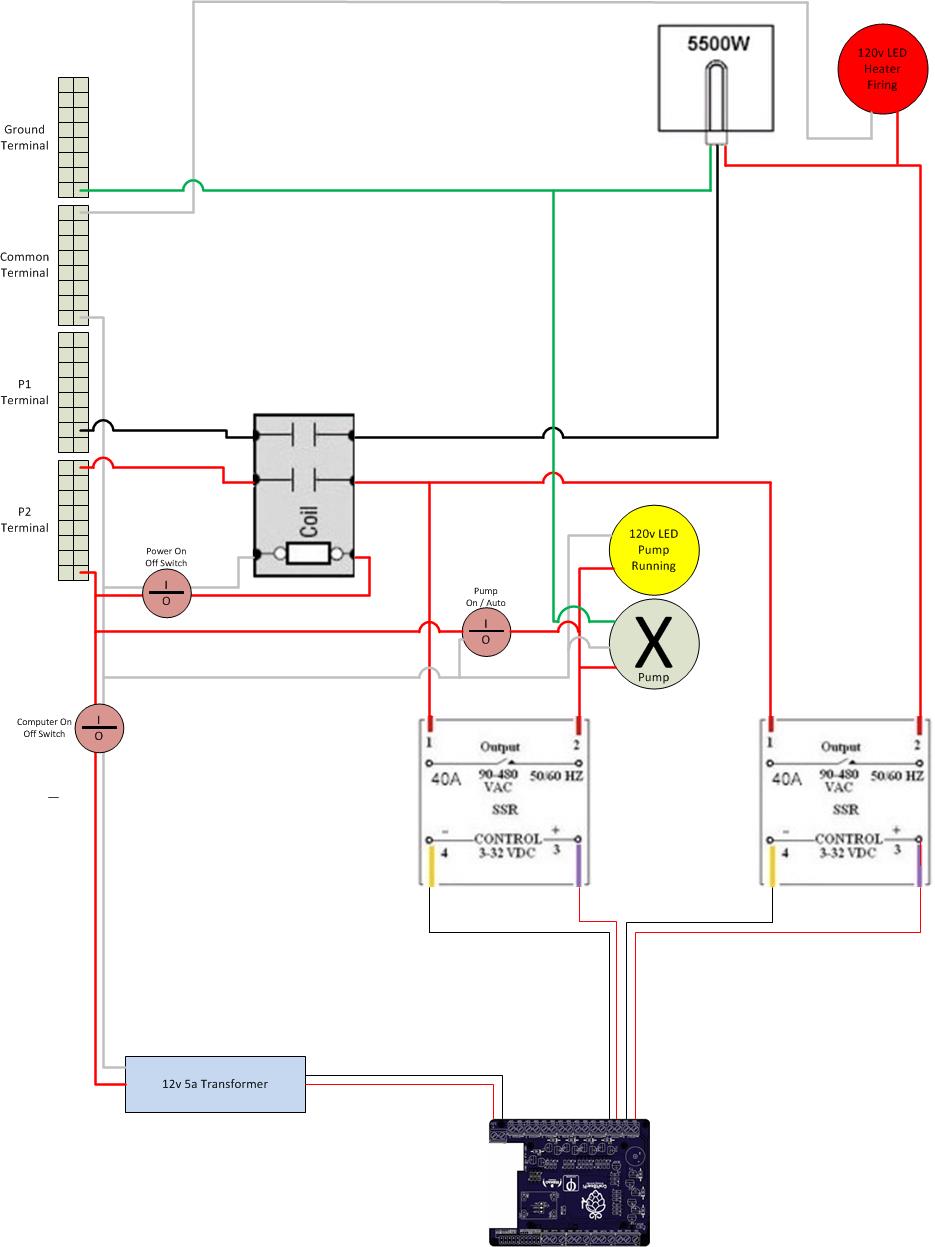

I'm a newbie to brewing beer so i figured I might as well jump in the deep end and create a all grain ebiab system. The first part I wanted to create a brew controller. I have a CraftBeerPi Extension Board and was wondering if anyone could provide some feedback on what I am planning on building. Diagram is attached, thank you for any input you may have.

I have the official craftbeerpi board. I am trying to set up the built-in buzzer. Does anyone know what gpio the software needs to be set to?

Try gpio25; that's what he used on earlier designs. I'm not at home right now, so can't check my board. Just received mine and haven't had a chance to fire it up yet, so don't know for sure.

I'm a newbie to brewing beer so i figured I might as well jump in the deep end and create a all grain ebiab system. The first part I wanted to create a brew controller. I have a CraftBeerPi Extension Board and was wondering if anyone could provide some feedback on what I am planning on building. Diagram is attached, thank you for any input you may have.

Will your power input be hard wired or pluggable? If hard wired, I'd consider a keyed or some sort of latching switch feeding the 12v power supply. This might help prevent cutting power to the Raspi through an inadvertent flip of the switch, which could lead to data corruption of the SD card. If you are running the OS off a USB drive, then that is less of a concern. Another optional item, which some may consider overkill, would be to put a LED across the outputs of the contactor. That way you have a clear indication of power to the SSR. That might be helpful when trouble shooting if the element does not fire.

Also, I think you have a drawing error in how you present the wiring to/from the pump switch. Although, being 120v you are probably OK switching just the hot leg. But you are showing 2 inputs and 1 output for that switch, which doesn't make sense. Again, suspect it is just an issue with the drawing.

Last edited:

Will your power input be hard wired or pluggable? If hard wired, I'd consider a keyed or some sort of latching switch feeding the 12v power supply. This might help prevent cutting power to the Raspi through an inadvertent flip of the switch, which could lead to data corruption of the SD card. If you are running the OS off a USB drive, then that is less of a concern. Another optional item, which some may consider overkill, would be to put a LED across the outputs of the contactor. That way you have a clear indication of power to the SSR. That might be helpful when trouble shooting if the element does not fire.

Also, I think you have a drawing error in how you present the wiring to/from the pump switch. Although, being 120v you are probably OK switching just the hot leg. But you are showing 2 inputs and 1 output for that switch, which doesn't make sense. Again, suspect it is just an issue with the drawing.

Thanks so much for the feedback. It will be pluggable to a 240v 30am gfci spa panel. I guess I need to do a little more research but i assumed supplying 12v to the craftbeerpi board would also power the raspberryPi. I guess i could also run usb power to the raspberryPi board if it makes sense.

All of the switches are illuminated so i should have a good idea if the contractor is activated.

On the pump wiring diagram I'm not sure if I have it correct but the idea was to be able to manually turn it on event of the pi was not on... maybe for cleaning or something.

Thanks again

Thanks so much for the feedback. It will be pluggable to a 240v 30am gfci spa panel. I guess I need to do a little more research but i assumed supplying 12v to the craftbeerpi board would also power the raspberryPi. I guess i could also run usb power to the raspberryPi board if it makes sense.

All of the switches are illuminated so i should have a good idea if the contractor is activated.

On the pump wiring diagram I'm not sure if I have it correct but the idea was to be able to manually turn it on event of the pi was not on... maybe for cleaning or something.

Thanks again

You are correct, the CBP board back feeds power to the Raspi through the GPIO pins. Do NOT power the Raspi through the USB power socket at the same time!

The point I was trying to make is that it is not a good practice to kill power to a Raspi if you run the full OS from a SD card. Yo'll want to shut it down from the program or shell command. Because of that, you don't really need the switch. I guess it gives you a convenient way to restart the Raspi without pulling and replugging the main power cord after you've shut it down from the program or shell. If your setup is permanent or semi-permanent , that could be advantageous by Triggering the Raspi to restart by cycling power. A momentary switch would be good for that purpose. Just don't use that switch to normally power down the Raspi or you will eventually corrupt the OS.

Last edited:

zombieyeast

New Member

- Joined

- Apr 13, 2017

- Messages

- 1

- Reaction score

- 0

Hi! Are there any issues with mounting 2 x 3ohm speakers in the control panel? using a 300x200mm metal rittal enclousure with 7inch touchscreen

I just purchased a hosehead uno and am trying to run cbpi. I have followed Corey's instructions and have been back and forth trying to trouble shoot and issue. My hosehead uno will not connect to cbpi and I get an error saying refusal to connect. It was mentioned to me that cbpi servers may be down and I was curious if anyone here had any answers to that being the case or any help trouble shooting.

Any help would be greatly appreciated.

Any help would be greatly appreciated.

You are correct, the CBP board back feeds power to the Raspi through the GPIO pins. Do NOT power the Raspi through the USB power socket at the same time!

The point I was trying to make is that it is not a good practice to kill power to a Raspi if you run the full OS from a SD card. Yo'll want to shut it down from the program or shell command. Because of that, you don't really need the switch. I guess it gives you a convenient way to restart the Raspi without pulling and replugging the main power cord after you've shut it down from the program or shell. If your setup is permanent or semi-permanent , that could be advantageous by Triggering the Raspi to restart by cycling power. A momentary switch would be good for that purpose. Just don't use that switch to normally power down the Raspi or you will eventually corrupt the OS.

Thanks you again for the feedback, This is great info for me that i did not consider. I think i will look into the momentary switches to shutdown and restart the raspberry pi.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Sorry if this has been answered before:

I have the official craftbeerpi board. I was hoping to either hook up two ssr's to the boards ssr/relay outputs or use a relay board hooked up to the ssr/relay outputs. I like the second option because the relay boards are small. Would I need a 12v relay board in this case? How would I wire it?

I am aware I can use a 5v relay board on the expansion slot instead but I was wanting to save those for later.

I have the official craftbeerpi board. I was hoping to either hook up two ssr's to the boards ssr/relay outputs or use a relay board hooked up to the ssr/relay outputs. I like the second option because the relay boards are small. Would I need a 12v relay board in this case? How would I wire it?

I am aware I can use a 5v relay board on the expansion slot instead but I was wanting to save those for later.

boomerbrian

Member

- Joined

- Dec 13, 2016

- Messages

- 24

- Reaction score

- 9

I am wanting to add an led that comes on when the element is on. I tried connecting an led to the DC side of my solid state relay but when I do I guess it drags the voltage down enough because the led comes on but the relay doesn't fire.

Anybody have any suggestions to how to do this?

Anybody have any suggestions to how to do this?

My personal belief is you should add a high voltage LED across the element power. This way you know when the element is actually powered. SSR's can fail closed, so the element could be on even though the SSR is not powered. This is rare, but does happen on occasion.

I have my chest freezer connected to Craftbeerpi. It's an elegantly simple setup, but I havent been able to get good temp regulation. I don't want to short cycle the compressor, obviously, so i haven't been brave enough to tighten down on and off triggers. Does anyone have on off fermentation trigger settings that work for them? I'm not using a heater, just the freezer. In addition to measuring the air temp, i also have a DS18B20 in fermenter thermowell. It is not used for control, just monitoring. Thanks.....

boomerbrian

Member

- Joined

- Dec 13, 2016

- Messages

- 24

- Reaction score

- 9

My personal belief is you should add a high voltage LED across the element power. This way you know when the element is actually powered. SSR's can fail closed, so the element could be on even though the SSR is not powered. This is rare, but does happen on occasion.

Good idea. Thanks.

I suggest you add as much thermal mass as possible - an empty freezer will need more compressor cycles. Jugs of water or more beer are a great way to do it. You can then shorten your hysteresis windows and/or have the compressor cycle less frequently.

That is true, I was just trying to get in the ballpark before I put beer in it.... Even with +2 on, 0 off I'm getting 10 deg swings every hour. My graph looks like an EKG. I suppose that may not be a problem as the liquid will not change temp as fast as the ambient but figured I'd check first.

How can you have a +2 hysteresis yet have 10 degree swings? Are you talking about different probes?

I'm exagerating a little, perhaps, but it's close to 10. A +2 on with 0 off at 55 deg lets it get up to 57. But even shutting off at zero (55) there is huge latency and it keeps cooling down to around 48 or 49. It stands to reason from what I've seen screwing with it the last couple days that the off setting is going to need to be really close to the on to account for the lag. I didn't want to experiment myself into a fried compressor.

Gotcha. I have same with my fermenter. More mass fixes it. Ultimately, I think the detecting volume needs to match the volume that matters.

I'm exagerating a little, perhaps, but it's close to 10. A +2 on with 0 off at 55 deg lets it get up to 57. But even shutting off at zero (55) there is huge latency and it keeps cooling down to around 48 or 49. It stands to reason from what I've seen screwing with it the last couple days that the off setting is going to need to be really close to the on to account for the lag. I didn't want to experiment myself into a fried compressor.

Is the temp probe sitting in liquid or air? One trick to keep the cycles down is have the temp probe sitting in a growler (or similar container) of water.

Then the water imitates the temp swing of the beer rather than the ambient environment in the freezer.

Hope this helps! [emoji482]

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 6

- Views

- 2K

- Replies

- 15

- Views

- 2K

- Replies

- 9

- Views

- 4K

Latest posts

-

Barleywine natural conditioning failed, switched to force carb, but now what? 😆

- Latest: BrewnWKopperKat

-

-

-

-

-

-

-