Lalo_uy

Well-Known Member

May be the SSR is overheating.

3.5"is way to small. 10"is bare minimum for something useful.

You can control temp for as many vessels as you want, but only have one steps execution thread.

Keep in mind that craftbeer pi has a web server, so you can log in on yur home network with a phone, tablet or PC and control the process. That is how I us mine.Hi guys. So I´m new to the raspberry but I was in the mood for building a craftbeerpi system. I just have a couple questions before beginning.

Can it handle multiple systems at once? For example 2 different mashing tuns?

I was going to buy a bundle from aliexpress, should i get one with a LCD screen? or the 3.5inch screen is too small for anything?

Right now I´m brewing with a brewmaniacEX system which works great, I´ve even translated it and adapted it to use a gas burner.

But I´m curious to try the raspberry.

Keep in mind that craftbeer pi has a web server, so you can log in on yur home network with a phone, tablet or PC and control the process. That is how I us mine.

I went out and bought a Crydom SSR that I thought was correct but now I'm not sure.. The input is 3-32V DC but I believe the output is 40A 100V VDC.. Do I need a VAC SSR for this to work properly?I had a similar problem when first using my system.

On occasion my SSR would "latch" and stay on. Usually after being 100% on for a while, like when bringing mash up to temp.

I found if I killed power to the SSR for a few minutes after I noticed it had 'latched" on sometimes it would go back to working off duty cycle and would be fine for the rest of the mash.

Researching I found most SSR's on the internet are fake, I think mine was a fake Futek.

I purchased some used 40 amp Crydom SSR's on ebay and haven't had a problem since.

When you said the LED light was off on the SSR to me that sounds like the Pi is doing its job.

Cheers!

If you want to control something that runs on AC power - which is usually the case - yes.I went out and bought a Crydom SSR that I thought was correct but now I'm not sure.. The input is 3-32V DC but I believe the output is 40A 100V VDC.. Do I need a VAC SSR for this to work properly?

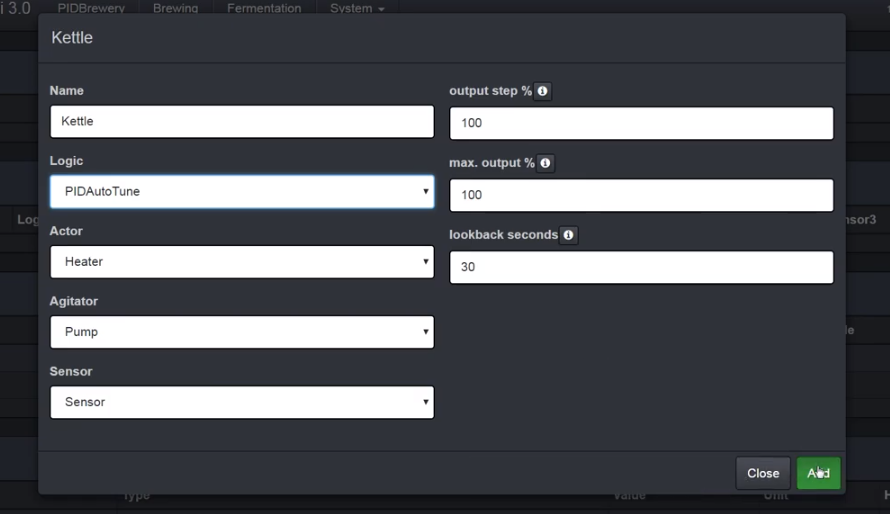

You really need to get in the habit of telling us what is happening specifically, and including logs if you are able. Otherwise "can't get it to work" could mean anything.Alright, new Crydom SSR is here. But I can't get PID Autotune to work! Everything I've tried so far and it just keeps failing. Any thoughts on what to change to help??

With the caveat that I don't run craftbeerpi - but I do understand PID loops, what it looks like is something is "oversized." What that "something" is depends on the setup. It could be the Kp is too large, the Kd not large enough, the heat source too strong, or the controlled mass too small. (Probably another 10 things it could be).Basically, I've run autotune with a couple of different settings now and it keeps failing at the end. I've done GPIO Simple & GPIO PWM, changed the lookback settings, etc. I have no problem getting to mash temp but from there it looks like it overshoots the temp by 1 or 2 degrees and holds that pretty constantly instead of the desired temperature. It'll run for about an hour or so and then eventually just fails. I've attached a log from one of my latest runs

[...]Is this SSR shot already? [...]

Since he appears to have other issues (which definitely could have resulted in the tuning failing) this may not help him but, thanks for pointing me there. I forgot all about the GitHub wikis.Descriptions of settings from the CraftBeerPi Wiki

Not to sound like a nerk, but are you sure everything is wired correctly?

I have the same wattage elements and tuned using practically the same volume of water using the default settings and came out with some very serviceable settings.

I can't help thinking something is either wired wrong or set up on the Pi incorrectly.

Is this SSR shot already?