Mtrhdltd

Well-Known Member

- Joined

- Aug 16, 2020

- Messages

- 191

- Reaction score

- 137

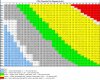

No experience myself, so I was just guessing.In my opinion, his 1800 psi is still too high even if it’s beer gas. Here is a picture of my 75/25 nitrogen/CO2 blend sitting at 66°. This tank is nearly new and reading 1400 psi (bottom gauge)... I don’t think it was ever much above 1500 when it was new.

View attachment 708379

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)