I’m currently working on designing a custom ebiab kettle that I plan to buy from Spike and am very conflicted about how to rig up the recirculation return. Having spent a fair amount of time reading various build threads, it seems to me that the options fall into three broad categories, each having its own advantages and tradeoffs:

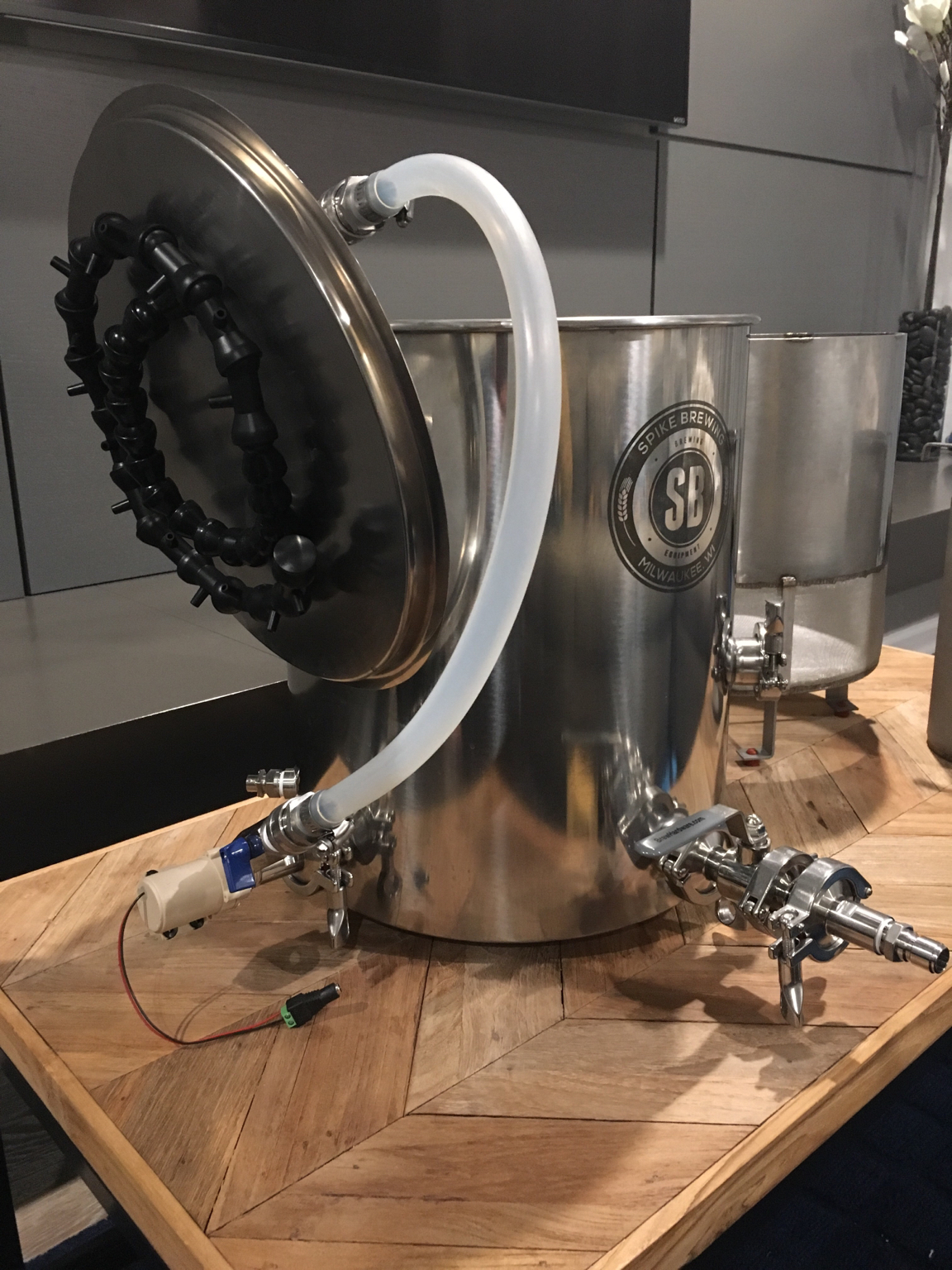

2. Recirculation port on the side toward the top of the kettle: I really like the design below from jmrybak. But I’ve read others say that recirculating through the side can interfere with the bag/basket (FWIW, I plan to start with a Wilser bag and false bottom. But I’m toying with the idea of switching to a mesh basket at some point).

3. Recirculating over the top of the kettle but not through the lid: I like this design from TexasWine.

It seems simple and effective, but you can’t fully close the lid—does this really matter, since recirculating should hold the mash temp constant anyway? I’ve also seen that some people just lay the tubing back on top of the mash, which seems by far to be the simplest option--any drawbacks of just doing that?

I’d be interested to hear others’ thoughts on the tradeoffs involved in these various design options.

(P.S., sorry for posting other people's pictures--I just really like all of your designs!)

- Recirculation port in the lid: I really like the design below from Metzen. But I’ve heard some people in other threads say that it can be annoying to have to have the lid on to recirculate/run the pump (see, e.g., here). I’d be interested to hear from others what they like/don’t like about recirculating through the lid.

2. Recirculation port on the side toward the top of the kettle: I really like the design below from jmrybak. But I’ve read others say that recirculating through the side can interfere with the bag/basket (FWIW, I plan to start with a Wilser bag and false bottom. But I’m toying with the idea of switching to a mesh basket at some point).

3. Recirculating over the top of the kettle but not through the lid: I like this design from TexasWine.

It seems simple and effective, but you can’t fully close the lid—does this really matter, since recirculating should hold the mash temp constant anyway? I’ve also seen that some people just lay the tubing back on top of the mash, which seems by far to be the simplest option--any drawbacks of just doing that?

I’d be interested to hear others’ thoughts on the tradeoffs involved in these various design options.

(P.S., sorry for posting other people's pictures--I just really like all of your designs!)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)