Do you have any DO data to back this up?

Can you be more specific as to the information you are looking for?

Do you have any DO data to back this up?

Can you be more specific as to the information you are looking for?

I'm wondering if you're having the same problem, i.e., you're stirring stuff up by putting it under pressure. Just a thought.

Any hard info on the difference between the dissolved oxygen in a closed transfer and a siphon transfer? You seem pretty passionate about it, just wondered if it was based on actual experimentation/data or just anecdotal experience.

It's kind of shocking to me that you could get that much o2 pickup from a still surface over a short period of time. Some the wort aeration experiments show folks that have a hard time getting over 4ppm when they shake the hell out of the carboy for 45 seconds. I don't doubt that your product might be a bit more shelf stable than someone that siphons, but I'd love to see brulosopher or someone do some DO and triangle tests. My hunch is that the difference is negligible for homebrew consumption. Now if your beer was sitting on a warm shelf in a beer store for 6-8 weeks, that might be a different story.

By the way, just to clarify, I'm genuinely curious, not trying to call anyone out.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I fill the keg from a faucet until it spills over, then i cap and connect the water supply to the OUT disconnect with the PRV open and a gas QD on until it spills out of both. I then take the gas QD off, and then very quickly close the PRV and shut the water off. I then use CO2 to push the keg empty. When I rack i connect the racking cane to the pressuzed keg and use the CO2 in the keg to purge the racking cane. I then pressurize the keg, open the PRV, and go.

When you do this. Are you adding star San to the keg? Or just assuming the tap water is clean enough to not cause any problems

At first I thought... "but I like to sanitize my kegs". But I guess it'd be easy enough to add an oz of star San before you started filling the keg with water.

Sometimes i'll do a rinse with a strong star san solution before the water purge. I don't waste 1oz of starsan per keg. Much of this depends on what the keg was doing previously. If it was holding beer and has been kept cold and unopened i'll do a mimimal cleaning.

Anecdotally, I've noticed an enormous difference in the flavor of ALL of my beers (hoppy and otherwise) when I started water purging my kegs. I fill the keg from a faucet until it spills over, then i cap and connect the water supply to the OUT disconnect with the PRV open and a gas QD on until it spills out of both. I then take the gas QD off, and then very quickly close the PRV and shut the water off. I then use CO2 to push the keg empty. When I rack i connect the racking cane to the pressuzed keg and use the CO2 in the keg to purge the racking cane. I then pressurize the keg, open the PRV, and go.

This is an impossibility for me due to my liquid-out tubes being cut about an inch above the bottom of the keg. I fear that I'd leave too much sanitizer at the bottom of my keg and it would water-down or create a strange flavor within my beer.

Today I kegged 5 gallons from my ssBrewTech Chronical. I did a closed-circuit transfer from the sample port and put the conical under CO2 pressure. Since I've had issues with hop trub getting stuck within the QD OUT and the OUTpost, I removed the internal components of both QD and OUTpost and the beer flowed quickly and seamlessly. Sure, once I filled the keg I had to unscrew the OUTpost to reassemble the internal components, but I'm assuming that there was minimal oxygen exposure from that space during the reassemble. Furthermore, the only volume of the beer exposed to oxygen was maintained within liquid-out tube. I can't see that oxygen-exposed volume escaping to oxygenate the rest of the beer. I'll let you know how the beer turns out. Does anyone see any issues/flaws with this method???

I destroyed a March Pump by not using bags.

"A volume of air smaller than would fill a shot glass, if

trapped in the keg, contains enough oxygen to raise the dissolved oxygen level

of a 20 liter batch of beer by more than 0.2 ppm. With a dissolved oxygen

level of 0.8 ppm, the fresh flavor of the beer fades within a week, even at cold

temperatures." -- http://www.germanbrewing.net/docs/Brewing-Bavarian-Helles.pdf

When I use my Torpedo kegs, a cup or thereabouts of Star-San is left in the keg after I've driven out the Star-San with CO2 in order to clear the keg of O2. I don't want that in my beer either, so I pop the lid, turn the keg upside down over the sink, and let that liquid out. There must be a little air replacing that Star-San, but it's minimal--just about, I imagine, what what you get when you reassemble your out posts.

I have very little Star-San left in my soda kegs by comparison, but I usually invert them to dump out whatever is in there anyway.

With a little purging after the beer is transferred, I just can't imagine I'm getting much if any noticeable oxidation. I don't taste it in my kegged beers, which tells me what I'm doing is sufficient.

How do you like those Torpedo kegs? Can you tell me more about them?

In addition to the fill with water/sanitizer-then force it out with CO2 method, this obviously won't work if I'm dry-hopping in the keg. Also, maybe another way to get the residual Star-San from the keg would be to just open the PRV and let it out from there? Obviously that would let in air too.

I'm thinking that replacing the components of my OUTpost would let in much less air then opening the top due to the small amount of surface area exposed to the air when the OUTpost is removed. Additionally, the volume exposed to oxygen is contained within the dip tube. Again, if anyone sees flaws with that, LMK!

I think they're great.

They work the same as a normal corny keg. They have no rubber on the base or comprising the handles, so I'm not getting black marks all over whatever. I also like that the kegs weigh less than the corny kegs which is helpful when hefting one over the collar of the keezer.

They have two versions--a shorter fatter version, and a taller, skinnier version. They also come in small, medium and large capacities. I have the large and small ones. Taking the small one (filled of course) to a party this weekend.

As far as the displace star-san w/ CO2 thing, why wouldn't it work with dry hopping? Isn't your keg empty regardless how you do it?

Will the posts for the torpedo work with standard CO2/Liquid QDs?

Regarding Dry-Hopping: You'll displace all that liquid with CO2, but you're going to have to open the top to pour hops in regardless - exposing the inside to air. I think the process of replacing liquid volume with CO2 volume is a solid procedure to assure that most oxygen is out of the keg, and potentially would work for me if a) my liquid dip tubes reached the bottom of my keg and could take out all of the sanitizer and b) if I wasn't dry-hopping my beer.

...

But think about this: as you pour *anything* into the keg, it's displacing the CO2 left behind. Maybe some O2 comes in with whatever you're pouring in, but you're pushing C)2 out as you pour anything in--which creates a positive OUT pressure.

...

Also, if your CO2 supply has more than 0.1 - 0.2 ppm O2, then you can't get enough O2 out, no mater what you do.

Brew on

In a confined space, you can create a Blanket of CO2. As far as air mixing when you open the lid, that is true but the bottom of the keg is still full of CO2. 0.1 to 0.2 PPM is an insignificant amount of O2 compared to the 99.9 to 99.8 PPM of CO2. Grain Silos where there is a natural CO2 "blanket", require breathing equipment to enter. You can create a visual blanket with some Dry Ice and water. The CO2 will evaporate and cover the water in a fog. Sure, it goes away, but if you did it in an enclosed contained, it would take a long time.As soon as you open the keg lid after a liquid purge, air starts mixing with the CO2 in the keg (CO2 "blankets" are a myth.) Whatever you add next won't come near to displacing enough gas to get out all the O2 you let in. You can still get the O2 out by doing multiple purges after filling the keg, but there no way to know how many purges you need without an O2 meter. So, you have to do extra purges just to be safe. Also, if your CO2 supply has more than 0.1 - 0.2 ppm O2, then you can't get enough O2 out, no mater what you do.

Brew on

In a confined space, you can create a Blanket of CO2. As far as air mixing when you open the lid, that is true but the bottom of the keg is still full of CO2. 0.1 to 0.2 PPM is an insignificant amount of O2 compared to the 99.9 to 99.8 PPM of CO2. Grain Silos where there is a natural CO2 "blanket", require breathing equipment to enter. You can create a visual blanket with some Dry Ice and water. The CO2 will evaporate and cover the water in a fog. Sure, it goes away, but if you did it in an enclosed contained, it would take a long time.

When I use my Torpedo kegs, a cup or thereabouts of Star-San is left in the keg after I've driven out the Star-San with CO2 in order to clear the keg of O2. I don't want that in my beer either, so I pop the lid, turn the keg upside down over the sink, and let that liquid out.

Even if you do that, you still have about 3 fl oz of liquid trapped because of the lid design.

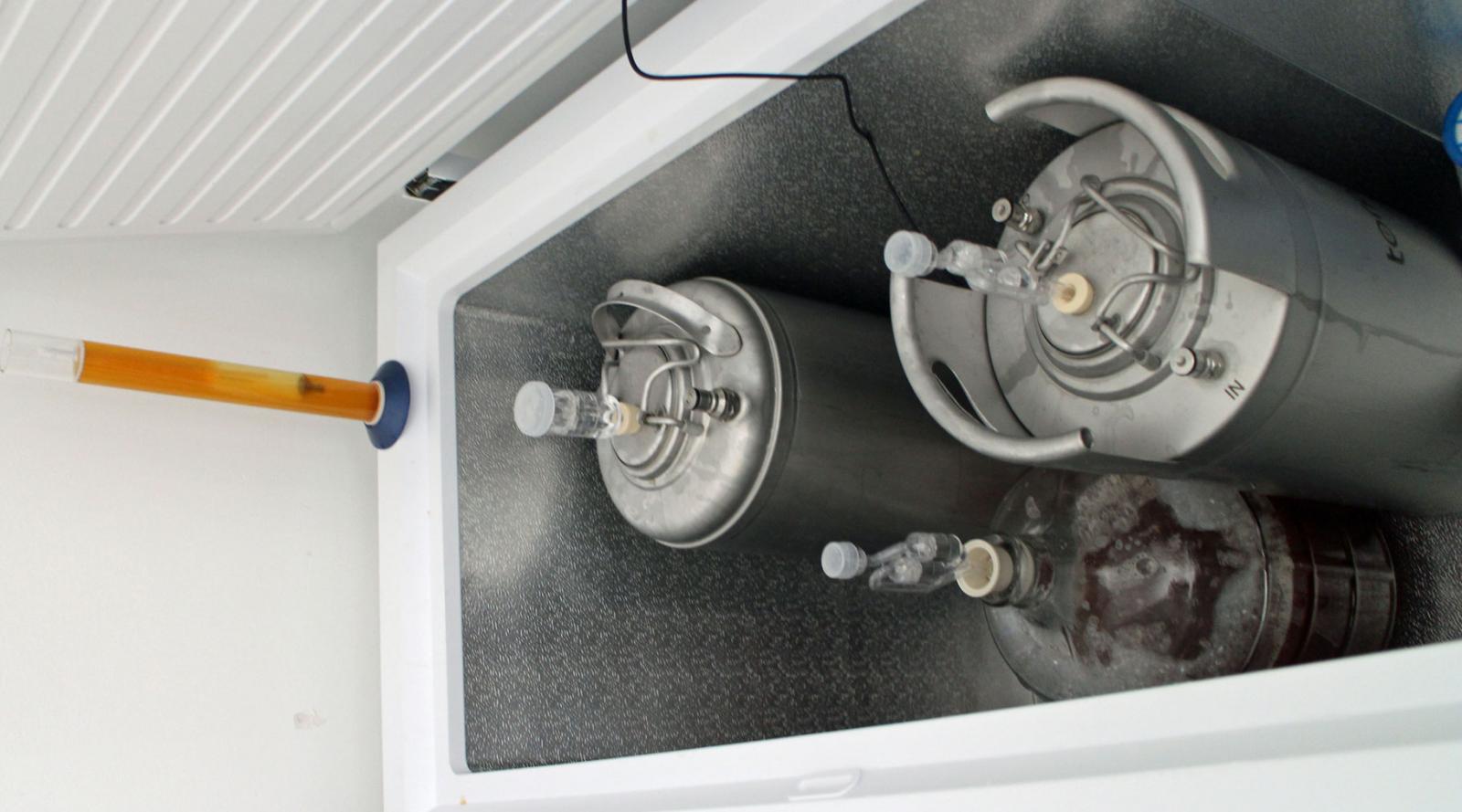

View attachment 360548

View attachment 360549

Brew on