OldSkrecz1

Member

- Joined

- May 26, 2020

- Messages

- 24

- Reaction score

- 5

Hello Everyone,

I was hoping that someone could help me out. I've been brewing for 15+ years now. I would consider myself an advanced brewer. But I am stumped right now. My last (4X) batches, have been stuck at 1.020.

current batch

10 Gallon

My current batch: Hazy IPA

25lbs of Briess 2row

1lbs of flaked oats

.5 40L

1lbs of sugar

Water was 50% RO and 50% filtered house water. added 2 teaspoons of Gypsum. Used 2 tbls of 5.2 PH stabilizer

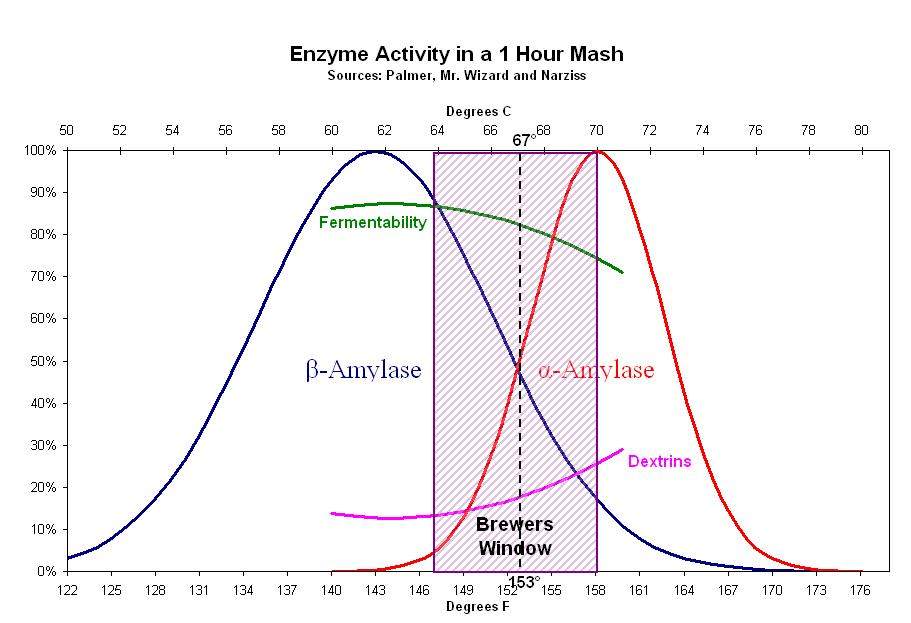

Mashed at 152 for 45 mins, then 149 15 mins.. then mashed out @168.

Hops

2 oz of Apollo 20Min

1oz each Cryo Citra/Simcoe/Mosaic at whirlpool (30Mins)

2 teaspoons of yeast nutrient @15mins

Yeast - 1056 (2 packs) 4000ml starter on Stir plate. Also, yeast was 1 month old.

Aerated for 45 seconds, with a beer stone and O2 tank.

ended up getting 1.063 SG

right now it at 1.020 after a week.

I have a morebeer 12 gallon temp controlled conical fermenter. it was set to 68F the whole time.

Other things I did before this brew.

Calibrated my hydrometer and all kettle thermometers.

What do you guys think? What am I doing wrong? In the past I could get to 1.012, with no problem.

I was hoping that someone could help me out. I've been brewing for 15+ years now. I would consider myself an advanced brewer. But I am stumped right now. My last (4X) batches, have been stuck at 1.020.

current batch

10 Gallon

My current batch: Hazy IPA

25lbs of Briess 2row

1lbs of flaked oats

.5 40L

1lbs of sugar

Water was 50% RO and 50% filtered house water. added 2 teaspoons of Gypsum. Used 2 tbls of 5.2 PH stabilizer

Mashed at 152 for 45 mins, then 149 15 mins.. then mashed out @168.

Hops

2 oz of Apollo 20Min

1oz each Cryo Citra/Simcoe/Mosaic at whirlpool (30Mins)

2 teaspoons of yeast nutrient @15mins

Yeast - 1056 (2 packs) 4000ml starter on Stir plate. Also, yeast was 1 month old.

Aerated for 45 seconds, with a beer stone and O2 tank.

ended up getting 1.063 SG

right now it at 1.020 after a week.

I have a morebeer 12 gallon temp controlled conical fermenter. it was set to 68F the whole time.

Other things I did before this brew.

Calibrated my hydrometer and all kettle thermometers.

What do you guys think? What am I doing wrong? In the past I could get to 1.012, with no problem.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)