BroccoliMangoAle

Member

- Joined

- Apr 15, 2018

- Messages

- 6

- Reaction score

- 11

Okay this is the first time I couldn't google a homebrewing question.

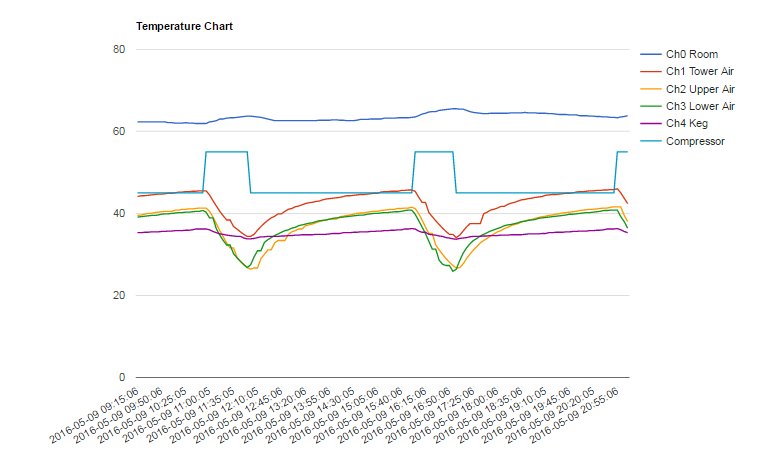

I got a chest freezer and a hot/cold power controller with a no-light heat lamp for heat and I'm trying to run some tests to see how it does keeping a fermenter full of liquid at 67 degrees. It seems to work pretty well mostly. I've got two waterproof sensors hanging in the water, one for the controller and the other for a Raspberry Pi that's graphing the temps on a web server I can hit on my home network to keep an eye on it. The temps are staying nice and tight since I started using water to test instead of just hanging the probes in the air inside the freezer.

The problem is that the water in the bottom of the fermenter is like 25 degrees cooler than the water at the top, regardless of where the probes are. So if the probes are in the bottom, the temps at the bottom stay right near 67, but the top is in the 90's.

I imagine with yeast activity swirling around in a wort the temps will be a little more uniform, but how do I get a uniform temperature throughout the fermenter after active fermentation is over? Big-ass stir plate?

All I can think to try is put some kind of insulation under the fermenter so it isn't sitting right on the freezer bottom, and making sure the heat lamp isn't pointing directly at the fermenter itself.

I got a chest freezer and a hot/cold power controller with a no-light heat lamp for heat and I'm trying to run some tests to see how it does keeping a fermenter full of liquid at 67 degrees. It seems to work pretty well mostly. I've got two waterproof sensors hanging in the water, one for the controller and the other for a Raspberry Pi that's graphing the temps on a web server I can hit on my home network to keep an eye on it. The temps are staying nice and tight since I started using water to test instead of just hanging the probes in the air inside the freezer.

The problem is that the water in the bottom of the fermenter is like 25 degrees cooler than the water at the top, regardless of where the probes are. So if the probes are in the bottom, the temps at the bottom stay right near 67, but the top is in the 90's.

I imagine with yeast activity swirling around in a wort the temps will be a little more uniform, but how do I get a uniform temperature throughout the fermenter after active fermentation is over? Big-ass stir plate?

All I can think to try is put some kind of insulation under the fermenter so it isn't sitting right on the freezer bottom, and making sure the heat lamp isn't pointing directly at the fermenter itself.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)