uptheirons

Well-Known Member

First time posting here! Awesome site with tons of information, so thanks to everyone.

I used to bottle my beer but now I have a spare fridge and went and bought a 20lb C02 tank, couple of corny kegs. I am overwhelmed with all the information out there so looking for some help in getting the right equipment and parts for a dual tap system (for now, but I will upgrade to more taps later).

What I have currently?

- 2 5gallon corny kegs

- 1 20lb CO2 tank

- purchased Micro Matic 842-2-PP regulator (on the way)

Thinking of getting

- CMB barbed end ball lock disconnect for gas

- CMB 1/4" ball lock disconnect for liquid

- 1/4" to 5/16" swivel nut for the liquid QD

- brass barbed nipple 1/4" MPT X 5/16" barb

- Red gas hose 5/16 ID, 9/16 OD - 24' for two lines and some extra (is this a lot?)

- EVABarrier (Not sure what size diameter or length) - I heard 10ft per beer line is recommended. Is that right?

I want to go with Duotight fittings with the EVABarrier but I am not sure which one to get and the number considering my setup.

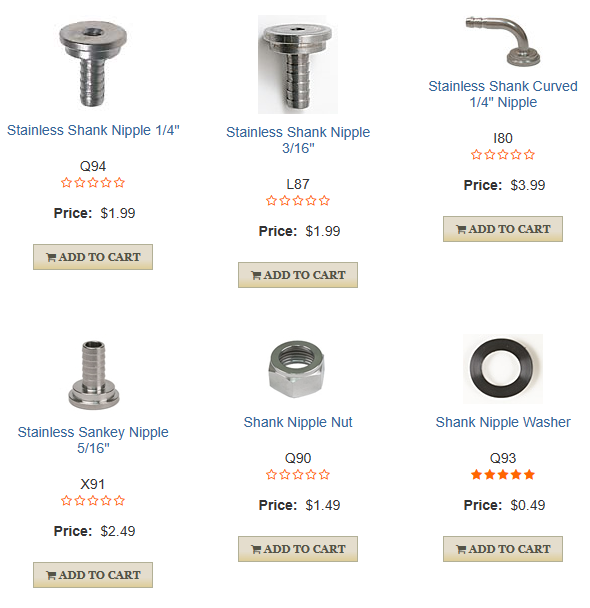

I have decided to keep my CO2 tank outside and drill two holes for the two gas lines so that I have enough room to add additional kegs in the future. I know I need the shanks, taps and handles. Any recommendations on what size to purchase? Any think else I may be missing?

Thank you!

I used to bottle my beer but now I have a spare fridge and went and bought a 20lb C02 tank, couple of corny kegs. I am overwhelmed with all the information out there so looking for some help in getting the right equipment and parts for a dual tap system (for now, but I will upgrade to more taps later).

What I have currently?

- 2 5gallon corny kegs

- 1 20lb CO2 tank

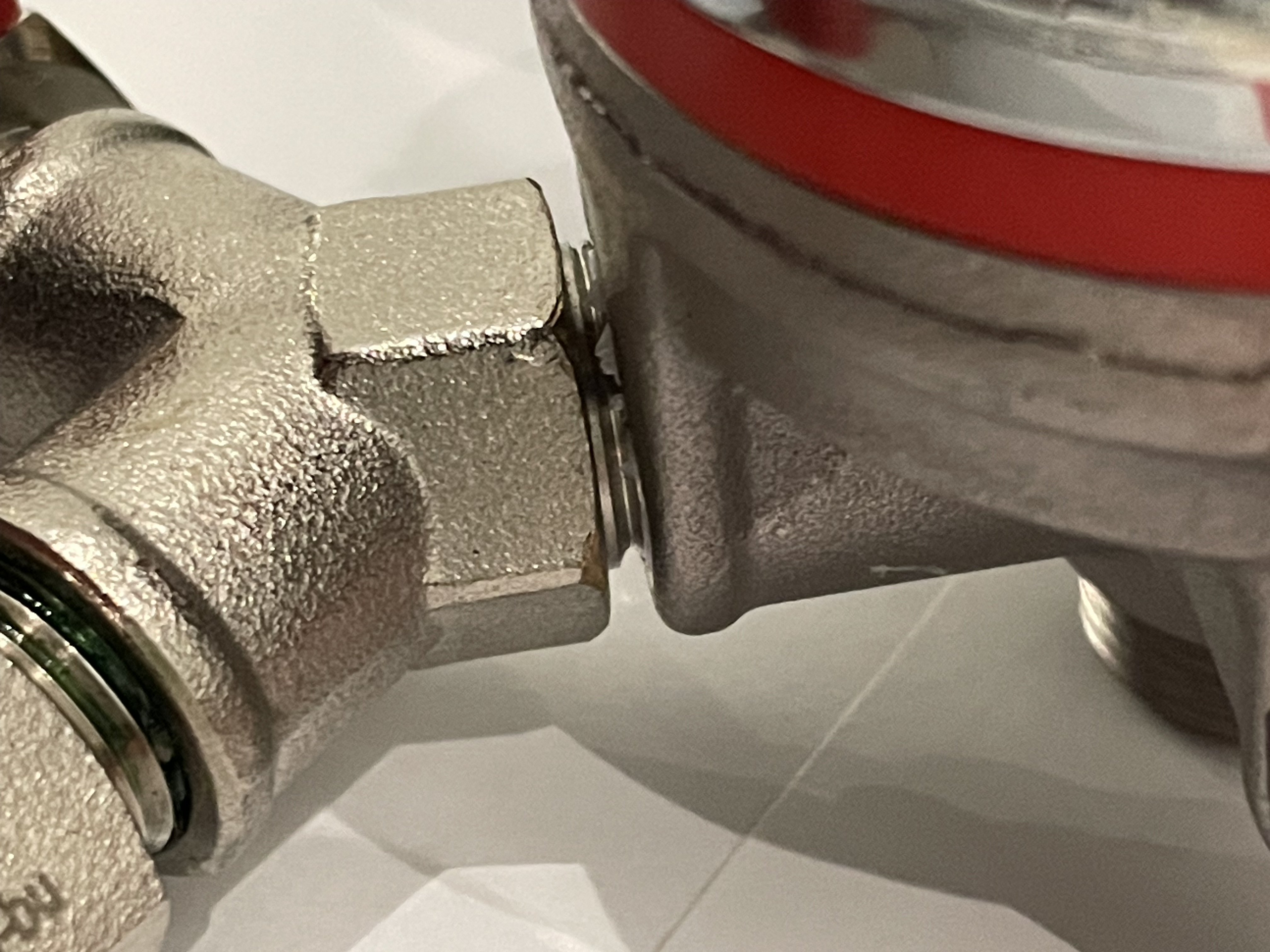

- purchased Micro Matic 842-2-PP regulator (on the way)

Thinking of getting

- CMB barbed end ball lock disconnect for gas

- CMB 1/4" ball lock disconnect for liquid

- 1/4" to 5/16" swivel nut for the liquid QD

- brass barbed nipple 1/4" MPT X 5/16" barb

- Red gas hose 5/16 ID, 9/16 OD - 24' for two lines and some extra (is this a lot?)

- EVABarrier (Not sure what size diameter or length) - I heard 10ft per beer line is recommended. Is that right?

I want to go with Duotight fittings with the EVABarrier but I am not sure which one to get and the number considering my setup.

I have decided to keep my CO2 tank outside and drill two holes for the two gas lines so that I have enough room to add additional kegs in the future. I know I need the shanks, taps and handles. Any recommendations on what size to purchase? Any think else I may be missing?

Thank you!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)