I totally agree with this... once primed

I have 3 brew sessions now using these pumps and have had the worst brew days in decades.

I ordered new stainless valves with updating various parts and quick disconnects for the pumps. I built a temporary control box to house the power supply, PWMs, and switches. (sloooow boat from China)

1st - I was excited about the entire redesign of my 3 tier gravity system. I installed a nylon false bottom into my mash tun I've had for many years and haven't really used. (I challenge anyone to find one now) I wanted to recirculate my mash for clarity then use the pump to circulate the wort through my counter flow and reduce to lower temps for hop adds. No fault of the pump the false bottom immediately clogged and I have a stuck mash. Getting a prime on the pump was 1/2 hour chore. It was connected straight to the valve in the correct fashion with a 1/2" silicone tube running back up into the mash tun. I finally got a runoff into a bucket and poured the grain into another so I could replace the false bottom with my very successful copper manifold. I re-added the grain and added the batch sparge water with no luck on priming again. I took off the pump and gravity fed to boil kettle as usual.

Same thing and the boil kettle. No prime, direct connect to valve. 1/2" tubing from outlet in the Upright position. Tubing hanging to the floor into a bucket to start a flow (normally). Open boil valve and nothing. I literally sucked on the end of the tubing to start a siphon. With all of this the boil continued well into an additional 45 minutes and all my numbers were off because of evaporation. 105 minute boil makes IBU's and volume F'd Up

2nd - I reduced the length of tubing thinking it was too long at 5' causing a challenge for a siphon. Same issues. Did get a siphon on the chiller with less length after a lot of playing around. Then I experienced the late add hop clogging issue and the pump stopped mid run. I gravity fed my fermenter, as usual. (and proven method)

3rd - Hot water only for testing.

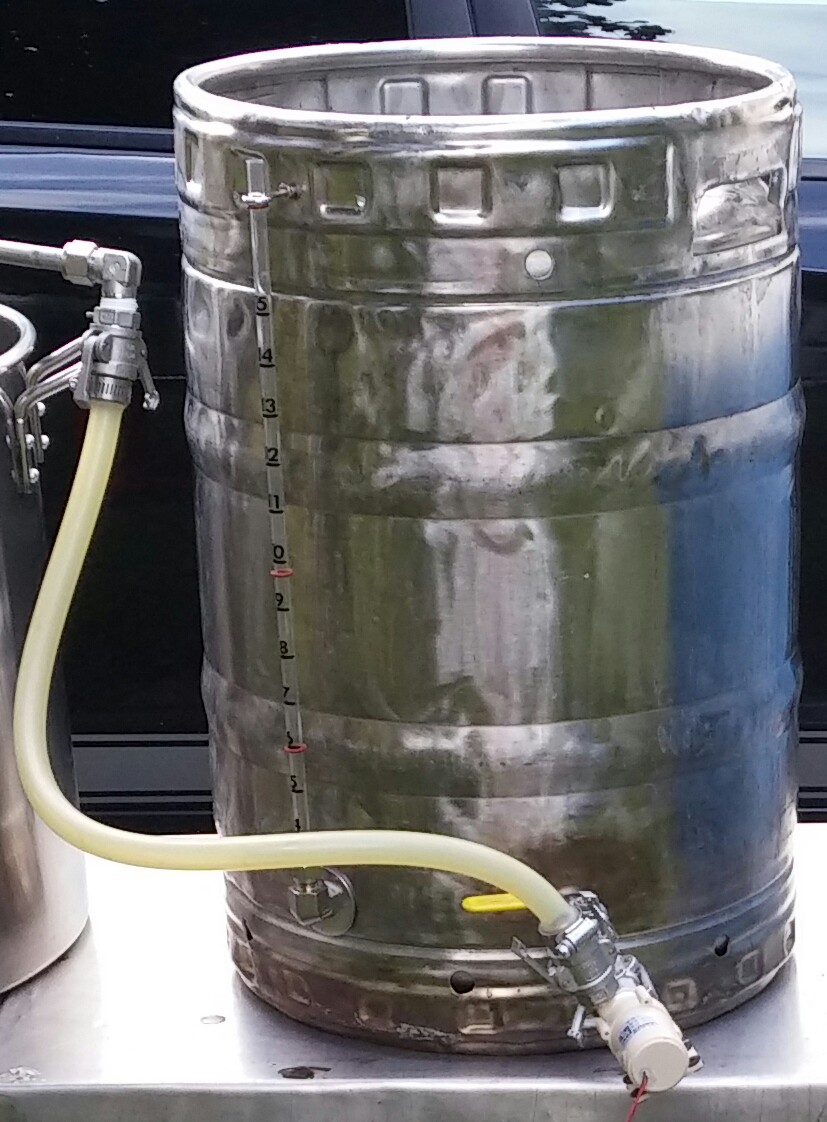

Had all my vessels close to the same level and mounted the pump temporarily with 2 screws to my bench BELOW about 6-10 inches. I installed barbs to everything and was going to try moving the tubing from one vessel to another as needed for the pump.

Heated water in my HLT and opened the valve placing the outlet tubing in a bucket to start siphon and NO flow. I played with the height of the outlet tubing and managed to fill the pump after playing with it for several minutes, so i turn on the pump. I filled the mash tun with 3 gallons and removed the HLT tubing by pinching the tube hard so as to not loose much level in the tube. I placed it on the Mash valve and outlet side to the kettle. I opened the valve and again Not A Damn thing.

I am SO done with these pumps. I can't tell you how I really feel here on this post after the money, time, redesigning, and excitement all wasted.

If there are any suggestions I'll appreciate it. I might give it one more shot but it WON'T be brewing. Maybe another water test.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)