Anyone know a good place to buy one of these pumps now?

Not a fan of eBay for the most part, so I bought here:

https://www.amazon.com/gp/product/B00DWORE6E/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

-sc

Last edited by a moderator:

Anyone know a good place to buy one of these pumps now?

The 24khz pwm controllers should work better for these pumps than the 16khz ones that have the readout on them from what I've read the higher frequency is better for driving motors reliably. I just marked reference points around the knob to function. As the readout.

Not a fan of eBay for the most part, so I bought here:

https://www.amazon.com/gp/product/B00DWORE6E/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

-sc

That's a fine power supply but for the same price or a few dollars more you can step up to a 10 amp. You might as well. The only down side is a larger footprint in your pump box or power distribution box.

http://www.ebay.com/itm/311614981831

That's a fine power supply but for the same price or a few dollars more you can step up to a 10 amp. You might as well. The only down side is a larger footprint in your pump box or power distribution box.

http://www.ebay.com/itm/311614981831

For anyone that comes across this link I rate that power supply 1 star.

Plugged it in, fuse popped, no load. It was delivered with a broken 'seal' on the casing. That ebay seller hasn't responded to me in over 24 hours now.

I give it 1 star because it was delivered faster than a Jimmy Johns sandwich.

This is the one I used, from Amazon:

https://www.amazon.com/gp/product/B0131Q3FU6/?tag=skimlinks_replacement-20

Just pointing it out AGAIN just as you mentioned the controller AGAIN for the other people who might care about the functionality aspect more than the "cool readouts" I'm sure they both work but since you gave your point of view I'll share mine. IMHO these pumps arent all that big and dont have tons of extra power why give more up just for extra bling on the panel? If you want to thats cool, its your choice.. but I dont see why your getting upset when I point out w the reasons one might not want to do it as well. And yeah since a lot of people on forums are notorious for not going back and reading previous pages I felt mentioning the frequency thing again since you were also mentioning the controllers again was pertinent to the conversation. If you actually read this whole thread you will find the same questions asked and answered dozens of times in it over and over.So you keep saying. And the hum is a factor for you. And you don't like boxes because losing the prime and or springing a leak is "scary".

Quite frankly a DC motor of this (im)precision isn't really gonna notice the difference. All motors are going to have a stall point at the low end that's above 0% duty cycle.

The controller with integrated digital readout has worked just fine. And who doesn't like cool LED readouts!?!

For anyone that comes across this link I rate that power supply 1 star.

Plugged it in, fuse popped, no load. It was delivered with a broken 'seal' on the casing. That ebay seller hasn't responded to me in over 24 hours now.

I give it 1 star because it was delivered faster than a Jimmy Johns sandwich.

Sorry to hear that. I know eBay can be a crap shoot.

I've generally had good luck with UXCELL stuff.

I hope your situation gets resolved quickly!

They really are small but they pump a lot for thier size! You can use a ball valve too but I just feel the pwm puts less strain on them by not using resistance against them to throttle them down.Just ordered this Lil fella http://m.ebay.com/itm/152060108309?_mwBanner=1

Also bought a 24V 3 amp power supply to run it. Thinking about getting a pwm too to throttle it down if need be.

I'd definitely recommend the second unit...

Thanks to this thread (all 1373 posts!!) I've pulled the trigger on the first steps to reducing my some 16 year old 3 tier system down to a weldless brew style single tier. I was on the 3rd step of my ladder asking myself, 'self... aren't you too old to be lugging 40 pound buckets of water up here?'

Special thanks to augiedoggy for his Parts List.

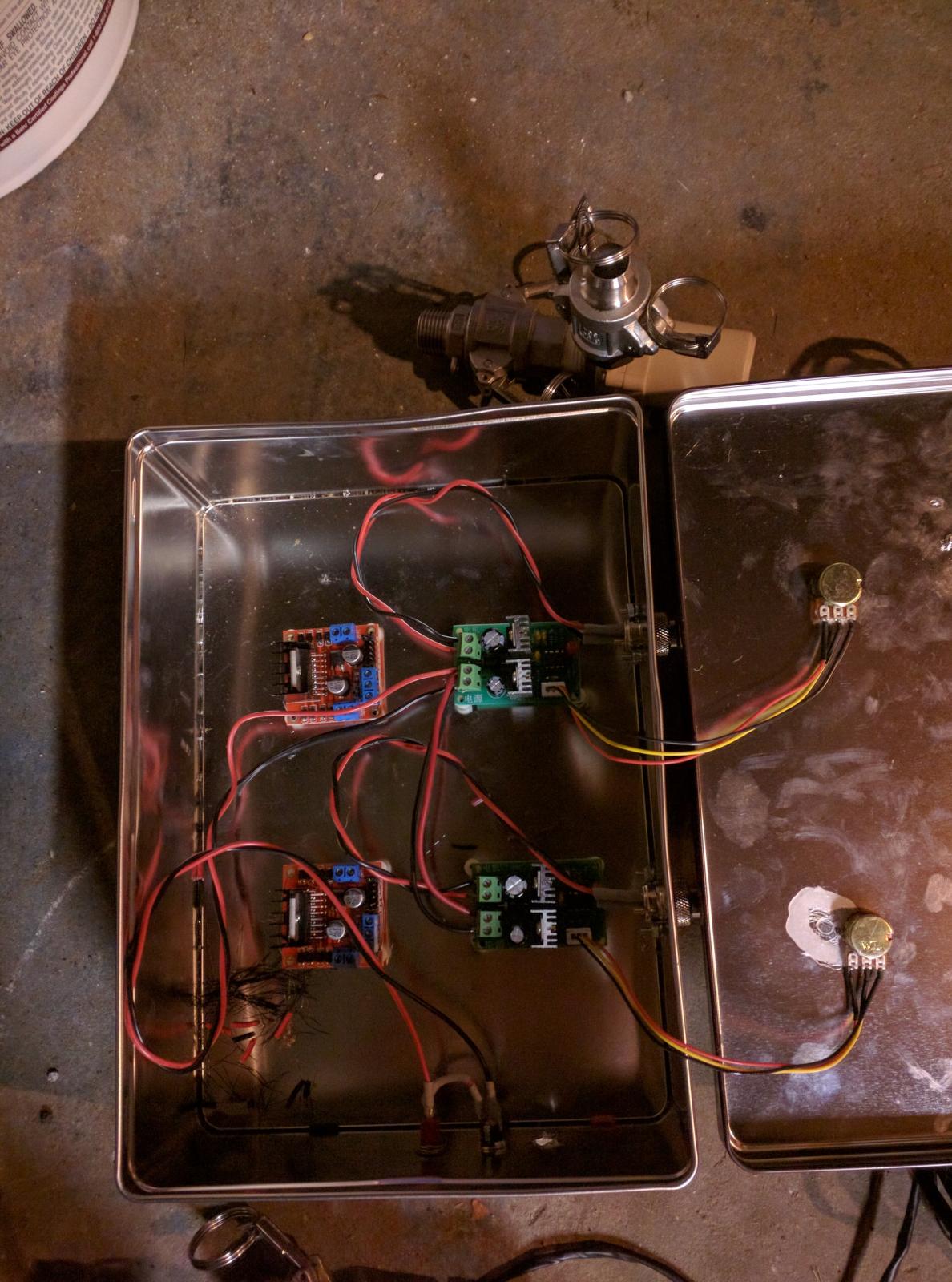

I planning on going with...

12v-3a Power Supply to a

Toggle Switch breaking the current to a

PWM Controler All enclosed in a

Project Box

Butt Spliced into

12v 3a Pumps.

The pumps (2) and controllers (2) should be here next week.

My questions are:

1. How hot will these switches and power supply get inside the project box?

2. What gauge wire to do all the connections?

3. If I like the setup I may add the second pump. Do I wire it along with the same posts on the toggle switch as the 1st controller?

I'm sure there will be more questions when I get to putting this together. I certainly appreciate any input and advice.

At 24v, how far/high can these pumps pump? I.e. the vertical distance from the outlet, while still running efficiently and not damaging the pump?

my chiller is mounted about 5 ft lower than the top of my conical and it has no issues pumping through the chiller and up to the top of the conical- even when turned way down in power.At 24v, how far/high can these pumps pump? I.e. the vertical distance from the outlet, while still running efficiently and not damaging the pump?