I linked those pumps a few times before hoping someone would try them... The 3.5a motor would simply be a more powerful motor as far as I can tell unless its actually the 36v version (they do make a 36v version according to the manufacturer) and the white box is a step up transformer/ boost as mentioned those take the additional amperage and convert it to higher voltage. someone with one would need to test the incoming voltage.

I upgraded my 3 12v pumps to the cheaper $18 24v ones and it was a worthwhile upgrade... close to a gallon more per minute.

I sent a message to the eBay seller asking how this pump managed 5.2 GPM. My question and the seller's response is below...

I've asked him for a picture of the inside of the white box. I'll post it here if they send one.

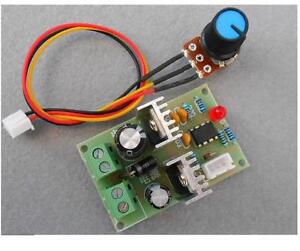

Boost converter to the higher voltage would be the logical answer. The next question is: Is it fixed voltage input or does it have the smarts built-in to accept PWM or variable input voltage to adjust RPM?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)