So…I have a keggle and I want to convert it from using a propane burner to an electric heating element.

BUT, I also want to just use the keggle and my grain basket and turn the whole setup into an “all-in-one” mash and boil.

Is this possible?

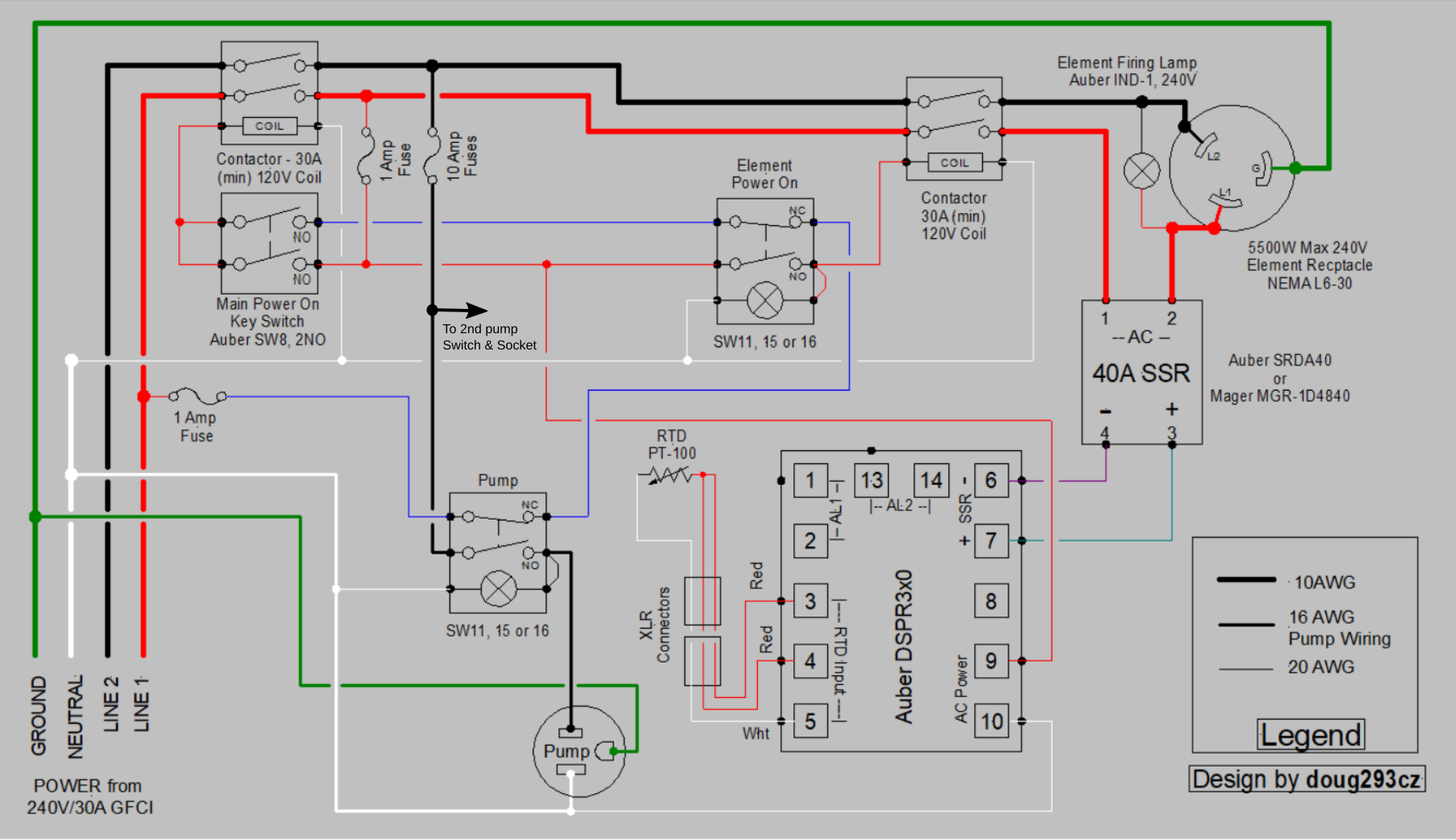

What can I use to control the heating element?

There is SO much info on here that I have literally spent DAYS searching for some kind of build that I could copy or modify but the more I searched the more confused I got. I have easy access to a 220v 50amp circuit, so a power source isn’t an issue…

PLEASE HELP!!

BUT, I also want to just use the keggle and my grain basket and turn the whole setup into an “all-in-one” mash and boil.

Is this possible?

What can I use to control the heating element?

There is SO much info on here that I have literally spent DAYS searching for some kind of build that I could copy or modify but the more I searched the more confused I got. I have easy access to a 220v 50amp circuit, so a power source isn’t an issue…

PLEASE HELP!!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)