Squeezer01

Member

- Joined

- Nov 25, 2008

- Messages

- 10

- Reaction score

- 0

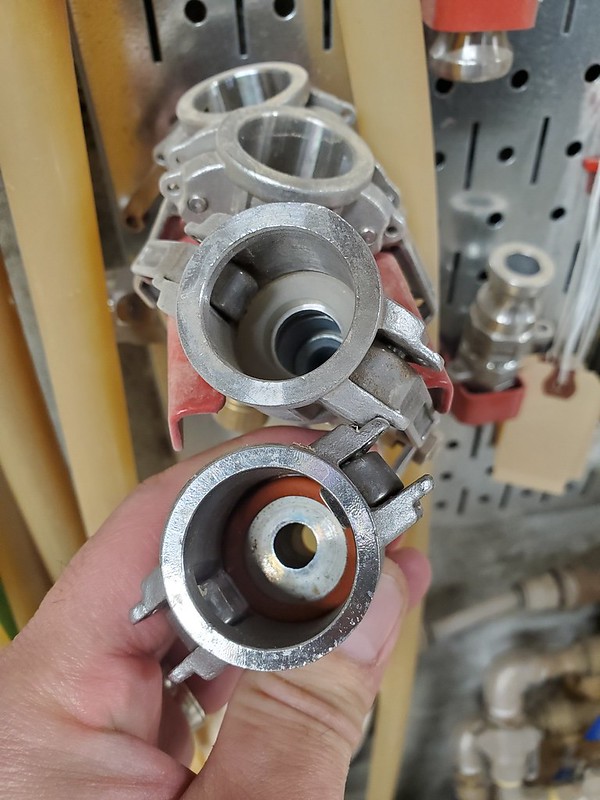

I am having difficulty closing the camlock fittings I recently purchased online. I seem to recall a thread that mentioned a supplier has thinner silicone gaskets but can’t locate the thread.

A couple of my fittings close without a whole lot of effort but some just won’t close at all, so I’d think thinner gaskets may solve the problem.

thank you for any suggestions ...

A couple of my fittings close without a whole lot of effort but some just won’t close at all, so I’d think thinner gaskets may solve the problem.

thank you for any suggestions ...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)