arfenarf

Member

- Joined

- Feb 2, 2016

- Messages

- 13

- Reaction score

- 8

So, the fridge was just down the street, and we could have it for free! DH and I wandered down to get it and pushed this 1989 side-by-side Frigidaire back up the road. Michigan potholes and little fridge wheels don't get on so well: we broke or lost three of four axles before we got it home. Good thing bolts swap in just fine.

Then we had a good look. Oh, yikes. Mold, rust, food residue, and mouse droppings. Euuch. It also had an Interesting Feature - the freezer side had two small doors. A bonus was its lack of icemaker and primitive electronics. But, thanks to all of you, I just blindly started taking it apart.

And ordered a couple of STC-1000s, computer fans, a little heater, a pair of duct dampers, some insulating foam, wire, and new fittings for my Dremel tool. Good thing the fridge was free.

I learned lots of stuff. I learned that 14-gauge wire is overkill. And I learned that fridge walls are made of tough stuff. I learned that no matter how carefully you think you're masking, if you rush the rustoleum job, you're going to have to clean up a mess. And after hours of chipping away at the stoopid thing, I learned to check in the cupboard to see if I might have forgotten that I own a jigsaw.

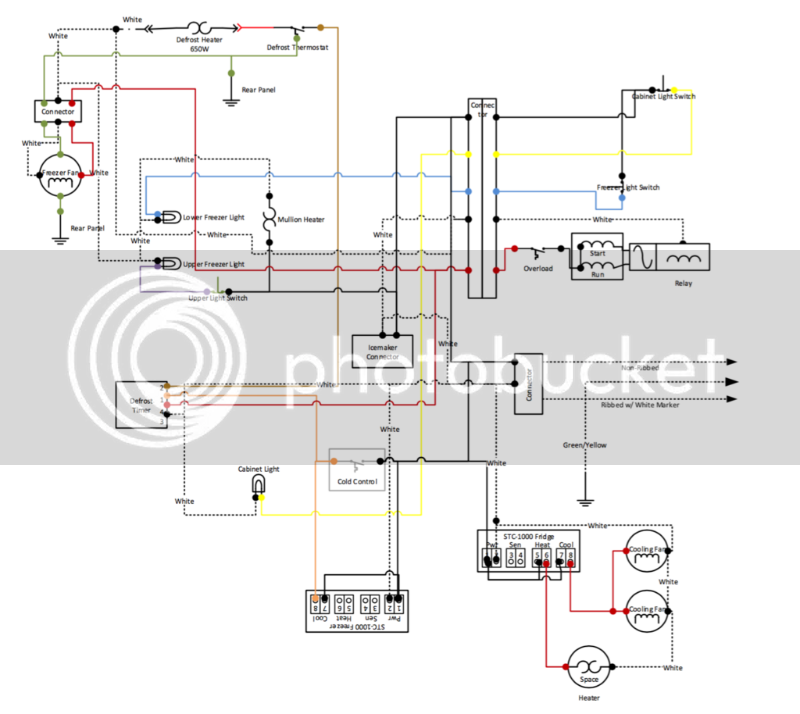

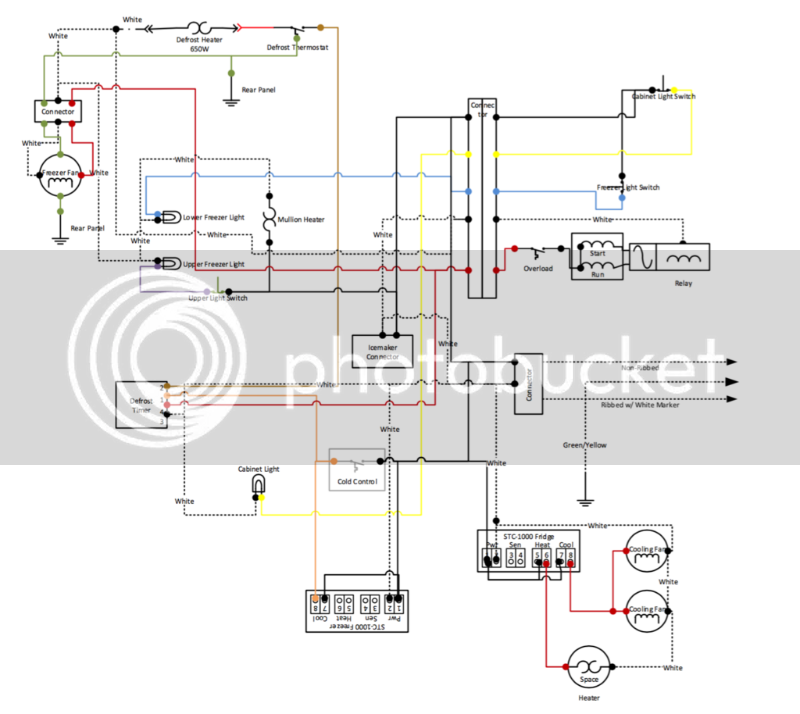

I pulled the thermostat out and started wiring. The wiring wasn't that hard after I figured out how to parse the ancient, stained diagram on the back of the fridge. At the moment, it's a bit of a rat's nest with screw-on connectors, because I wanted to be able to troubleshoot easily. Now that it's running well and proven, I'll redo some of the wiring with tidier, more permanent junctions, particularly on the neutral wire.

Many of you built outlets into your fridge: I chose to hardwire. I also opted to mount the controllers inside the fridge for now, because I think they'll be swapped for a brewpi or the like before too long, and I didn't want to make more holes in the doors than I needed to.

The upper damper was replaced with a fan blowing into the fridge compartment. The lower hole by the crisper drawer was replaced with a fan blowing into the freezer compartment. Both were wired into the fridge-side STC-1000's cooling circuit. The little space heater went into its heating circuit. Each fan has a one-way damper (like the ones on dryer ducts) to try to keep the sides a little separated. On the freezer side, I just moved the fridge's thermostat circuit onto the cold side of the second STC-1000.

This photo was taken at what was probably the low point from the refrigerator's point of view. Wires all ahoo, shrouding off, doors off, and no end in sight. DH really loves me and said not one single word about the ongoing state of our garage.

Then we had a good look. Oh, yikes. Mold, rust, food residue, and mouse droppings. Euuch. It also had an Interesting Feature - the freezer side had two small doors. A bonus was its lack of icemaker and primitive electronics. But, thanks to all of you, I just blindly started taking it apart.

And ordered a couple of STC-1000s, computer fans, a little heater, a pair of duct dampers, some insulating foam, wire, and new fittings for my Dremel tool. Good thing the fridge was free.

I learned lots of stuff. I learned that 14-gauge wire is overkill. And I learned that fridge walls are made of tough stuff. I learned that no matter how carefully you think you're masking, if you rush the rustoleum job, you're going to have to clean up a mess. And after hours of chipping away at the stoopid thing, I learned to check in the cupboard to see if I might have forgotten that I own a jigsaw.

I pulled the thermostat out and started wiring. The wiring wasn't that hard after I figured out how to parse the ancient, stained diagram on the back of the fridge. At the moment, it's a bit of a rat's nest with screw-on connectors, because I wanted to be able to troubleshoot easily. Now that it's running well and proven, I'll redo some of the wiring with tidier, more permanent junctions, particularly on the neutral wire.

Many of you built outlets into your fridge: I chose to hardwire. I also opted to mount the controllers inside the fridge for now, because I think they'll be swapped for a brewpi or the like before too long, and I didn't want to make more holes in the doors than I needed to.

The upper damper was replaced with a fan blowing into the fridge compartment. The lower hole by the crisper drawer was replaced with a fan blowing into the freezer compartment. Both were wired into the fridge-side STC-1000's cooling circuit. The little space heater went into its heating circuit. Each fan has a one-way damper (like the ones on dryer ducts) to try to keep the sides a little separated. On the freezer side, I just moved the fridge's thermostat circuit onto the cold side of the second STC-1000.

This photo was taken at what was probably the low point from the refrigerator's point of view. Wires all ahoo, shrouding off, doors off, and no end in sight. DH really loves me and said not one single word about the ongoing state of our garage.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)