Lol... I already got the SS wire brush for my angle grinder, so I'll use that instead of a scrubber. It is funny, but it's better to work smart, not hard. Also, I just like to experiment. If I didn't want to experiment, I would've used the SS wire brush right off the bat and not wasted my time. It would've been done in a couple minutes. However, I could only find speculation on this topic, so I figured it was time to dick around with some chemicals and document the results. I'll be done experimenting tonight, and I'll post the results soon after.

Earthbound,

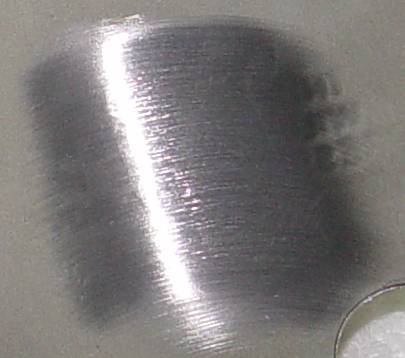

You really don't want to use a stainless wire wheel.

It will create deep scratches that may make it harder to clean in the future.

The stainless scrubby would be much gentler. If that doesn't work, then resort to the wire wheel.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)