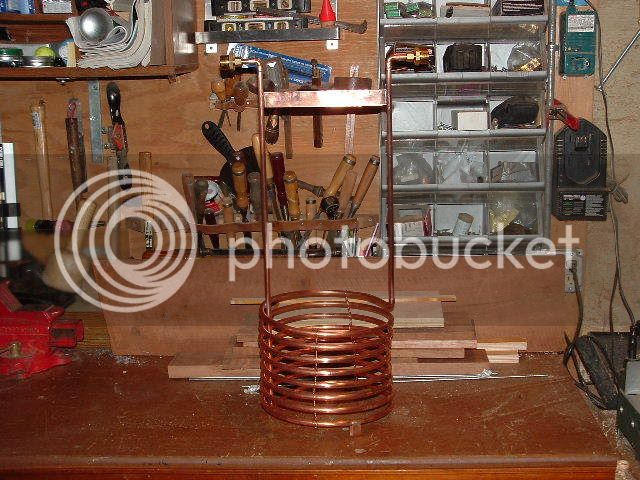

I got a coil of copper from our shop, I'm going to clean it up and make a wort chiller out of it. But I don't want to kink the copper trying to bend one end through the middle to get both ends on one side.

Is it ok to solder or braise a 90 on the bottom to get both ends on top or will the solder effect my wort?

Is it ok to solder or braise a 90 on the bottom to get both ends on top or will the solder effect my wort?