Garnet Heart

Member

- Joined

- Mar 7, 2018

- Messages

- 14

- Reaction score

- 2

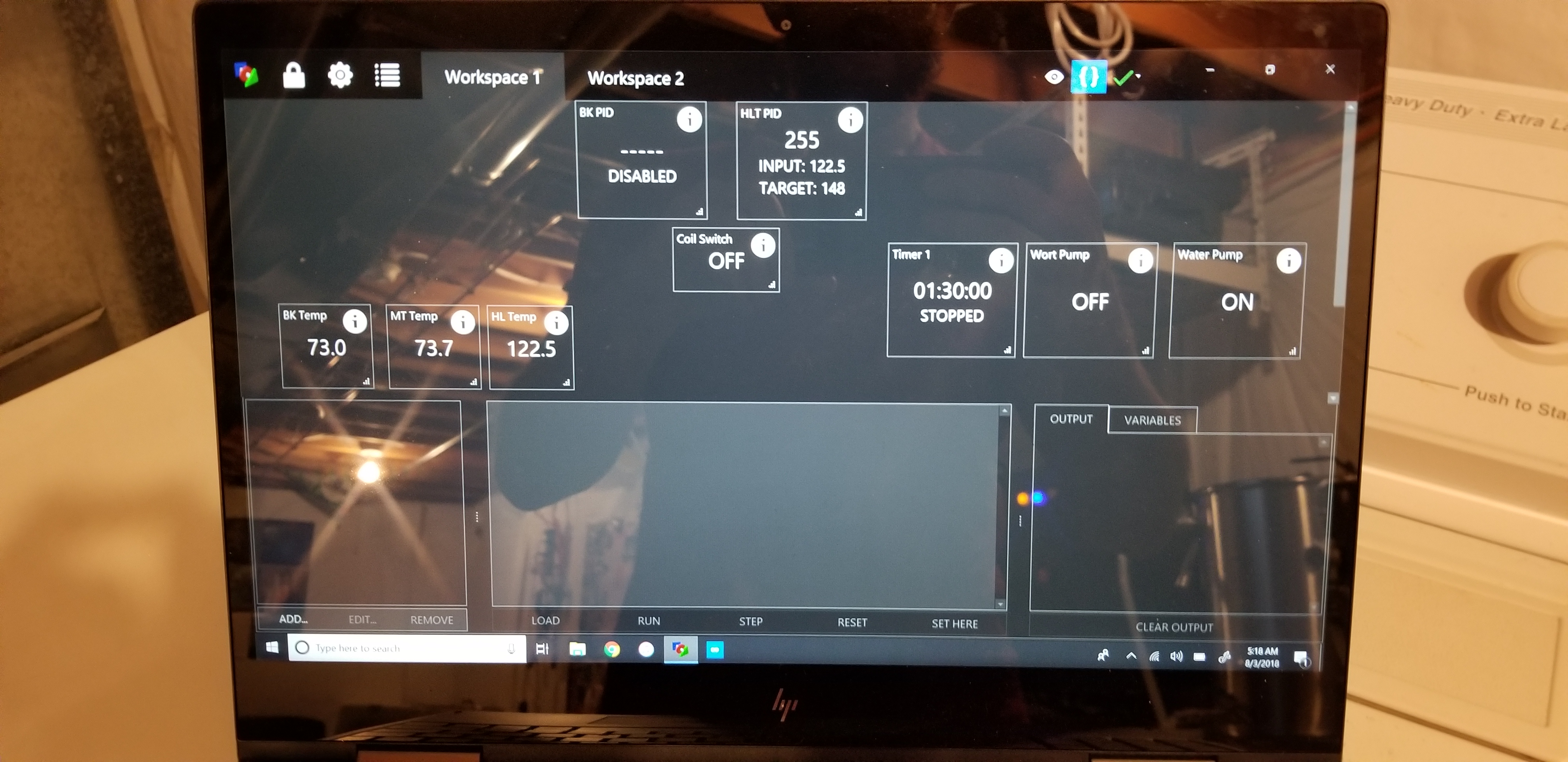

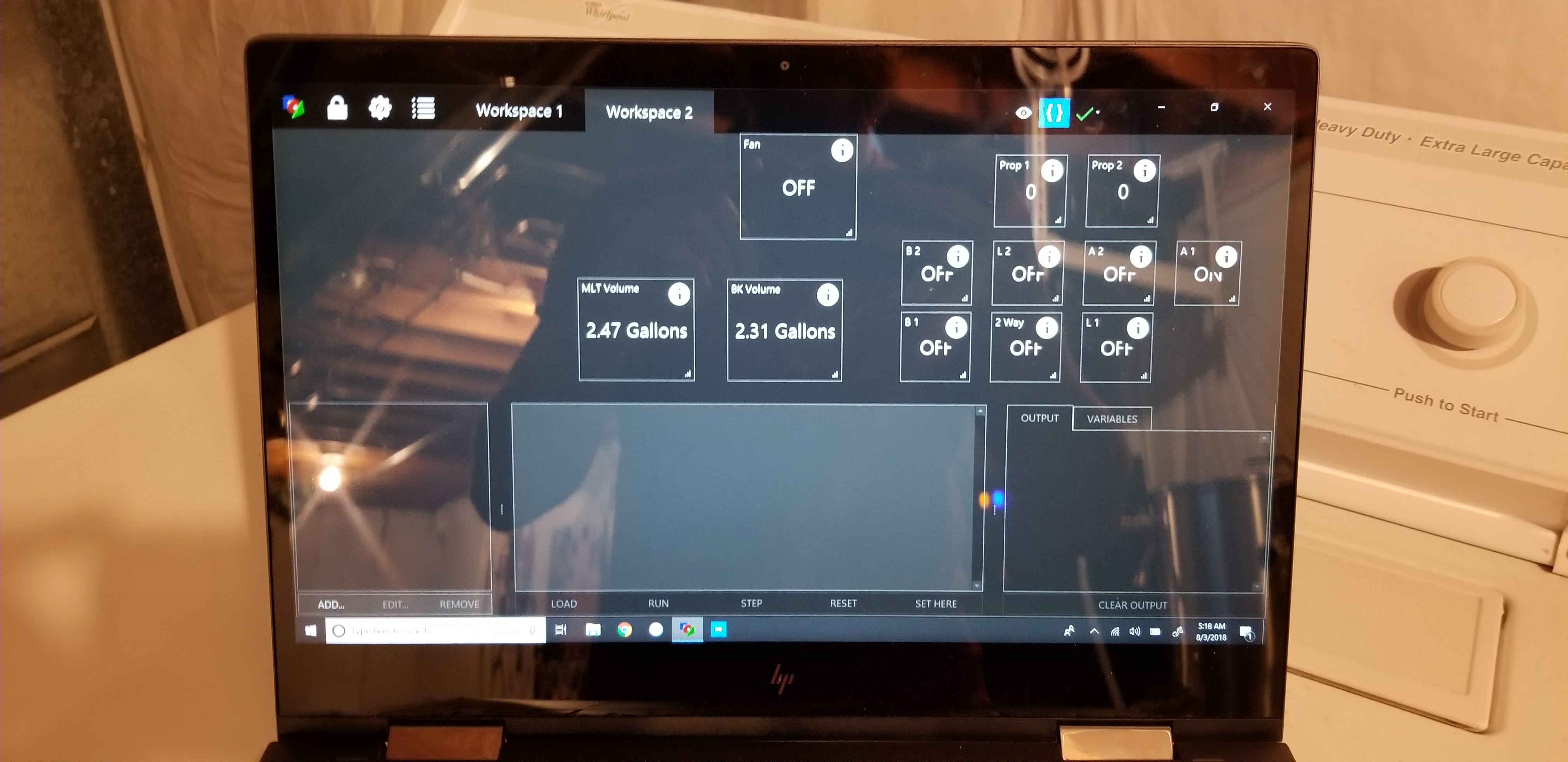

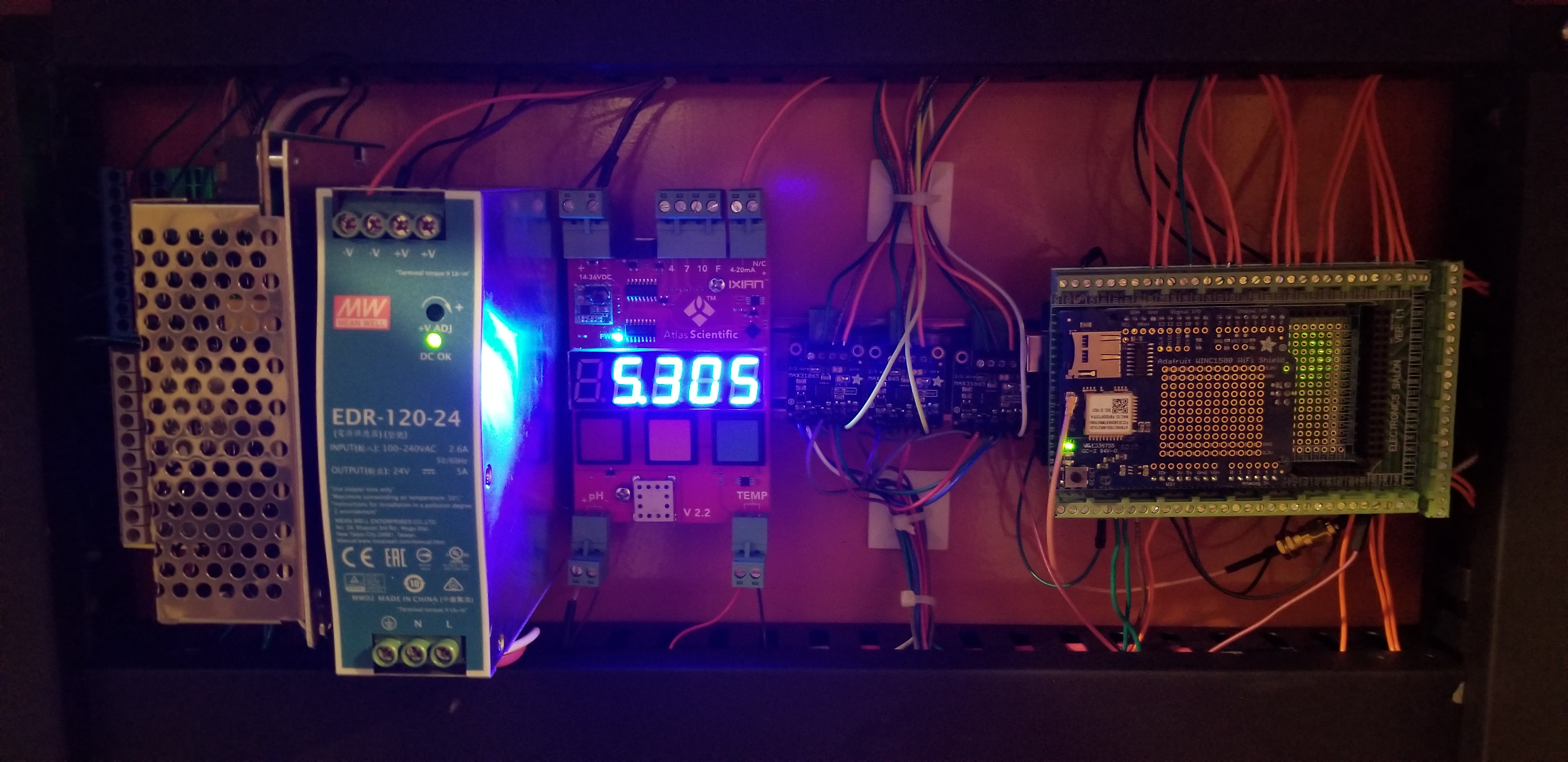

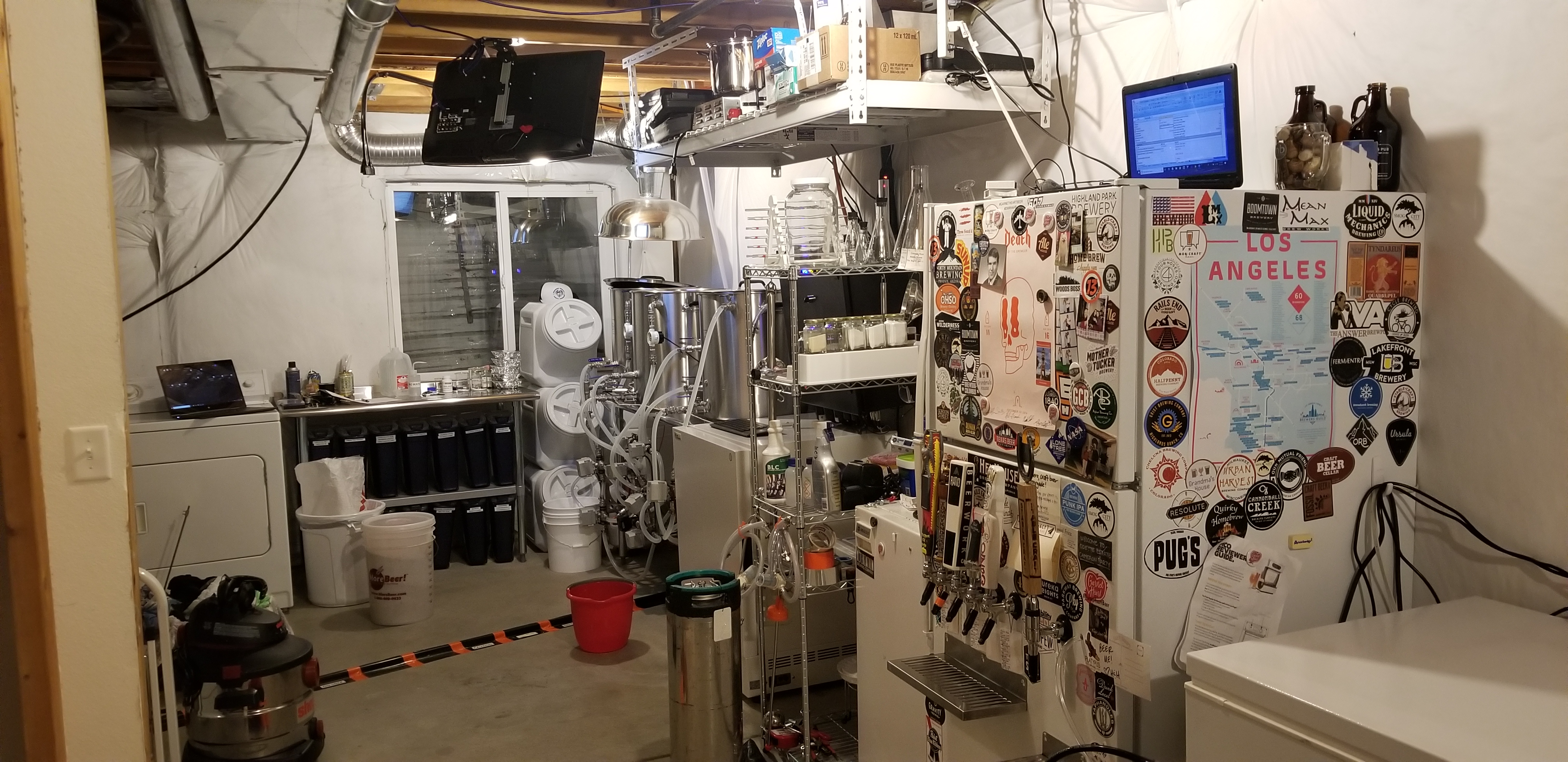

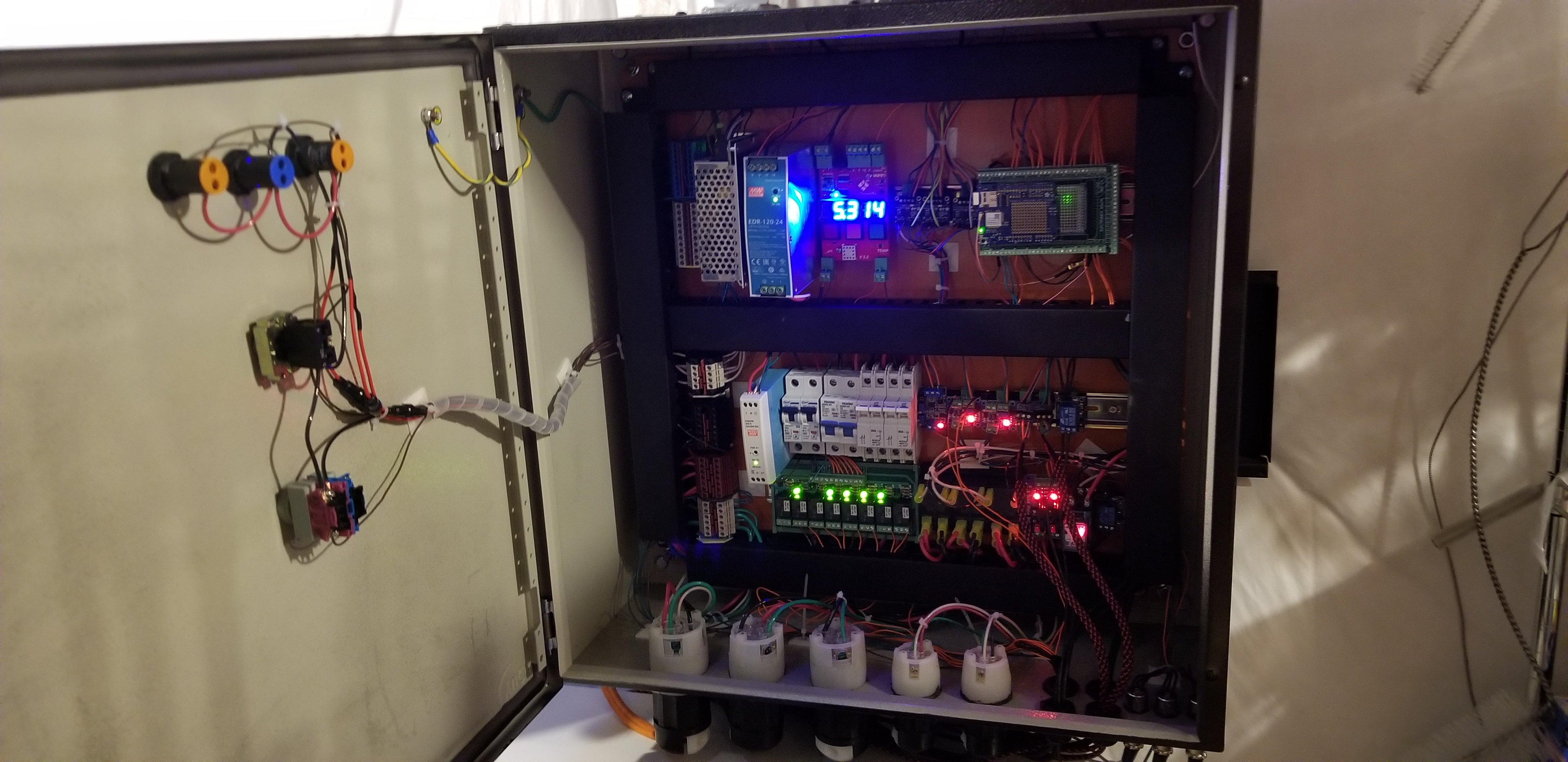

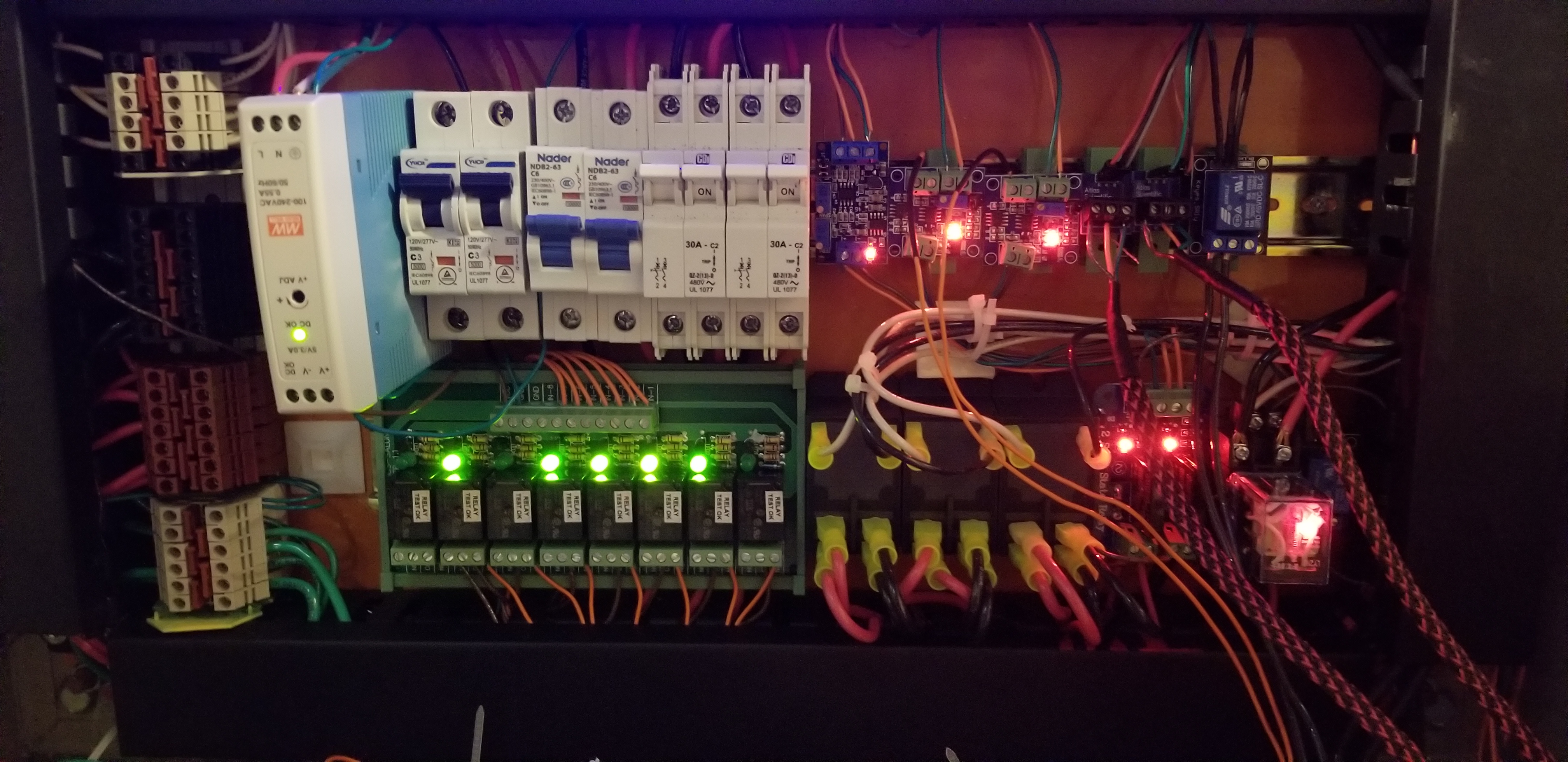

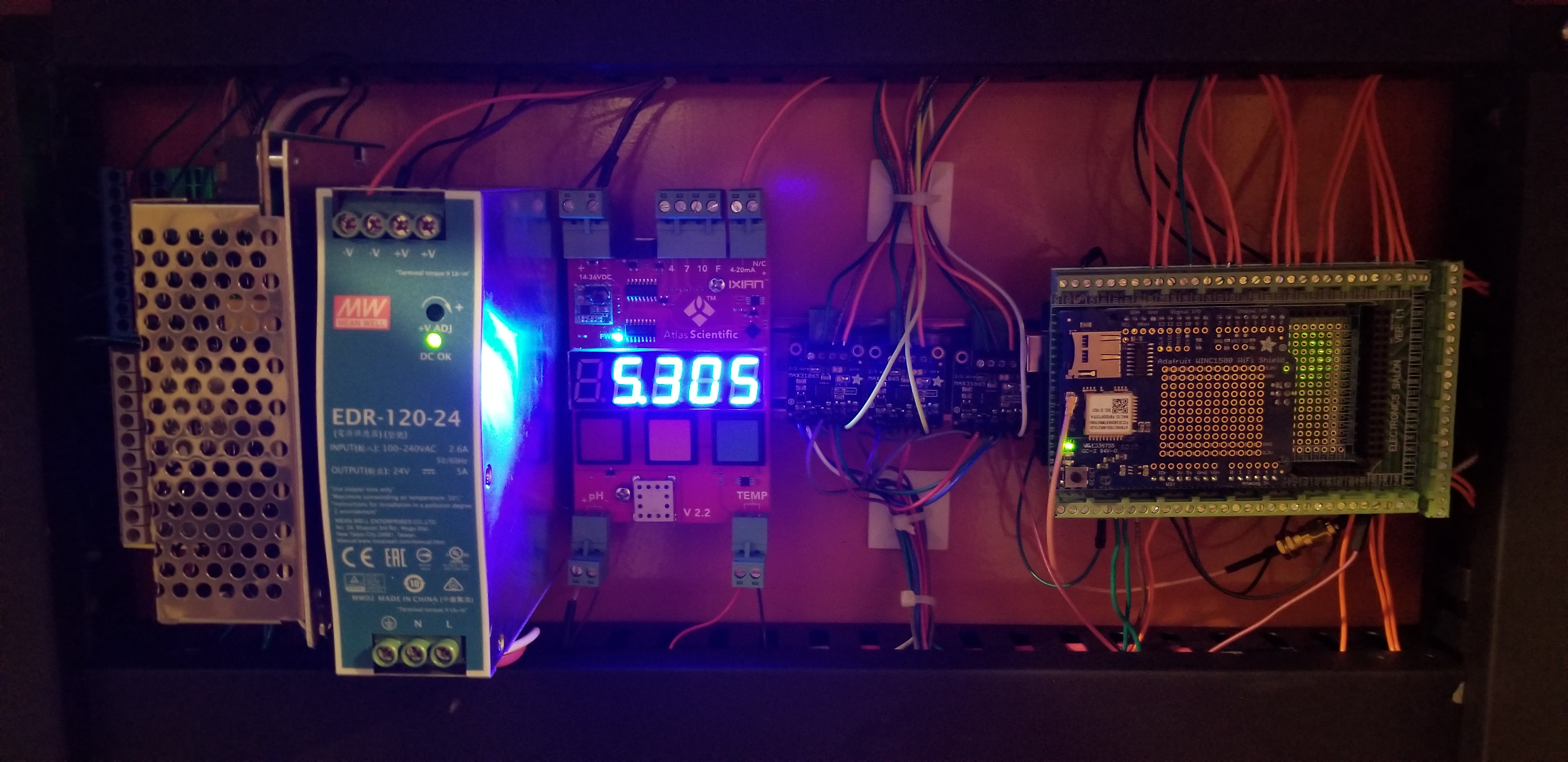

So I have been meaning to write this up for a while as I just finished my Brucontrol build. First off, I need to say how great BrunDog was when helping with the questions I had. Especially when it came to sourcing the diaphragm pressure sensors I am using. (i had some in hindsight really dumb questions as well)

Still currently in development is my scripting, as life seems to get in the way of me actually sitting down and prototyping the script i want to use.

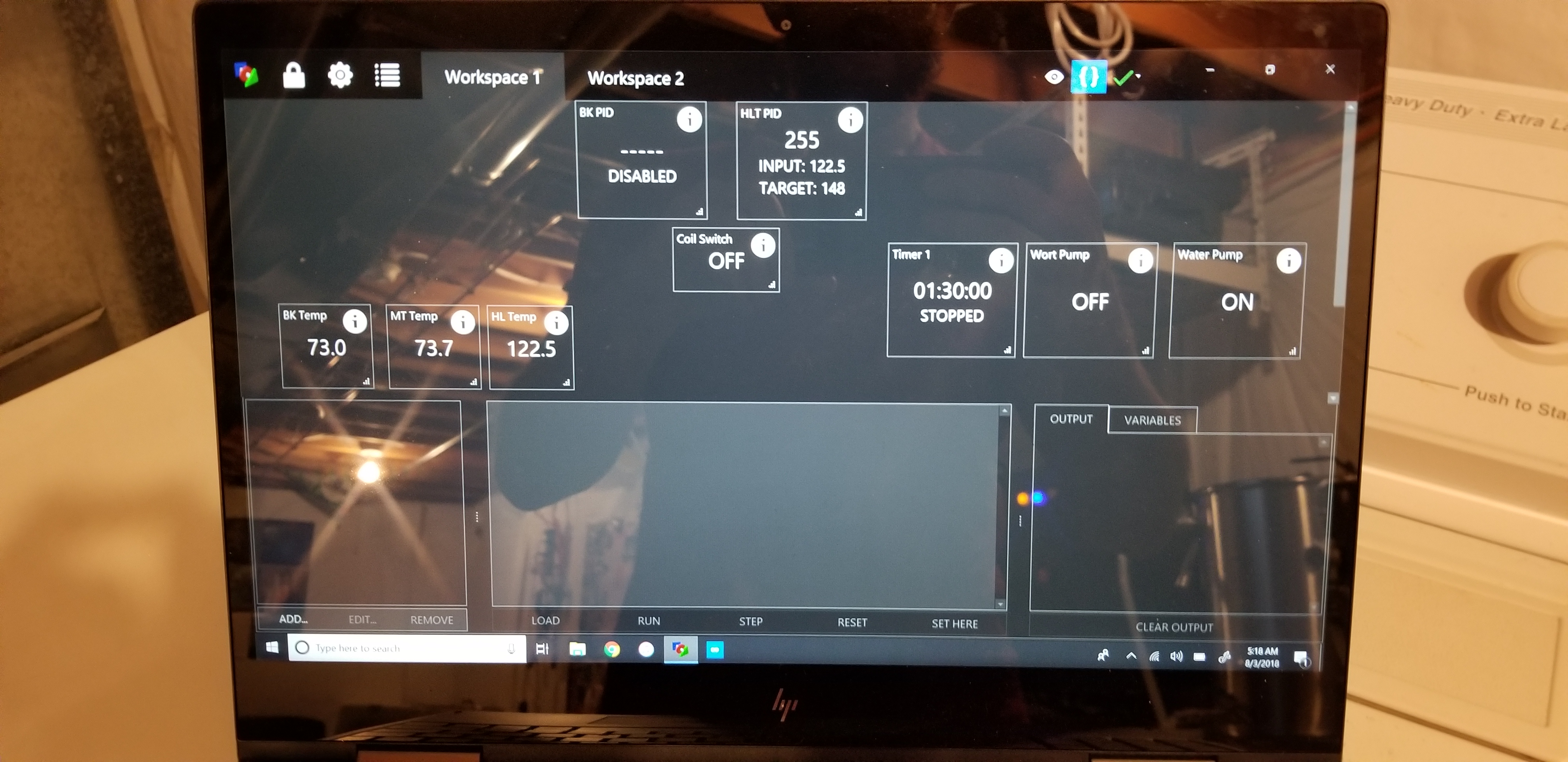

So far, I have put 2 x 12 gallon batches through the new panel. A Gose and a Bo Pils and as far as I can tell the software does its job incredibly well.

I have a few more kinks to work out here and there as my process improves due to the addition of new valves and electrical wires, but overall I am extremely happy.

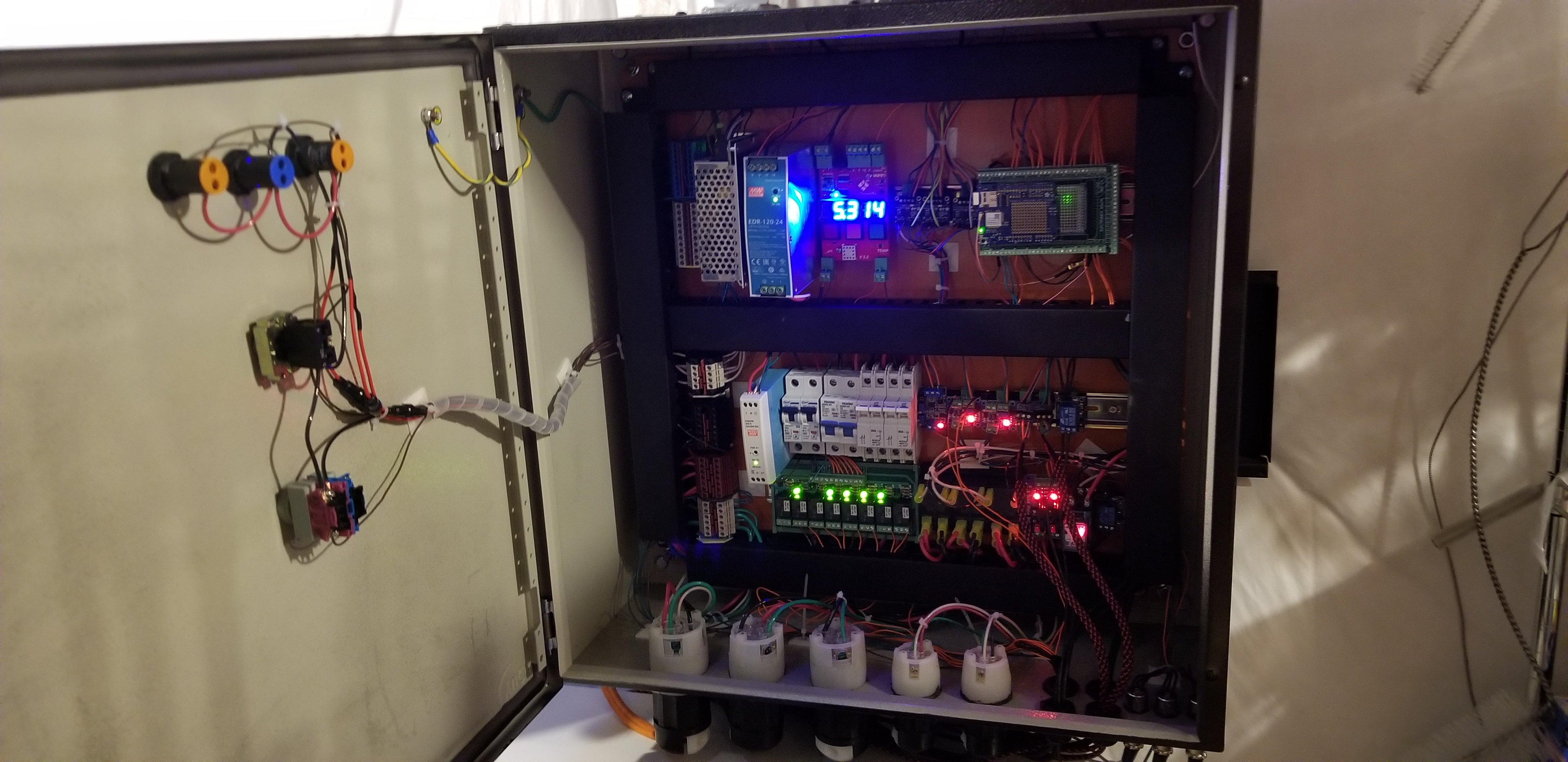

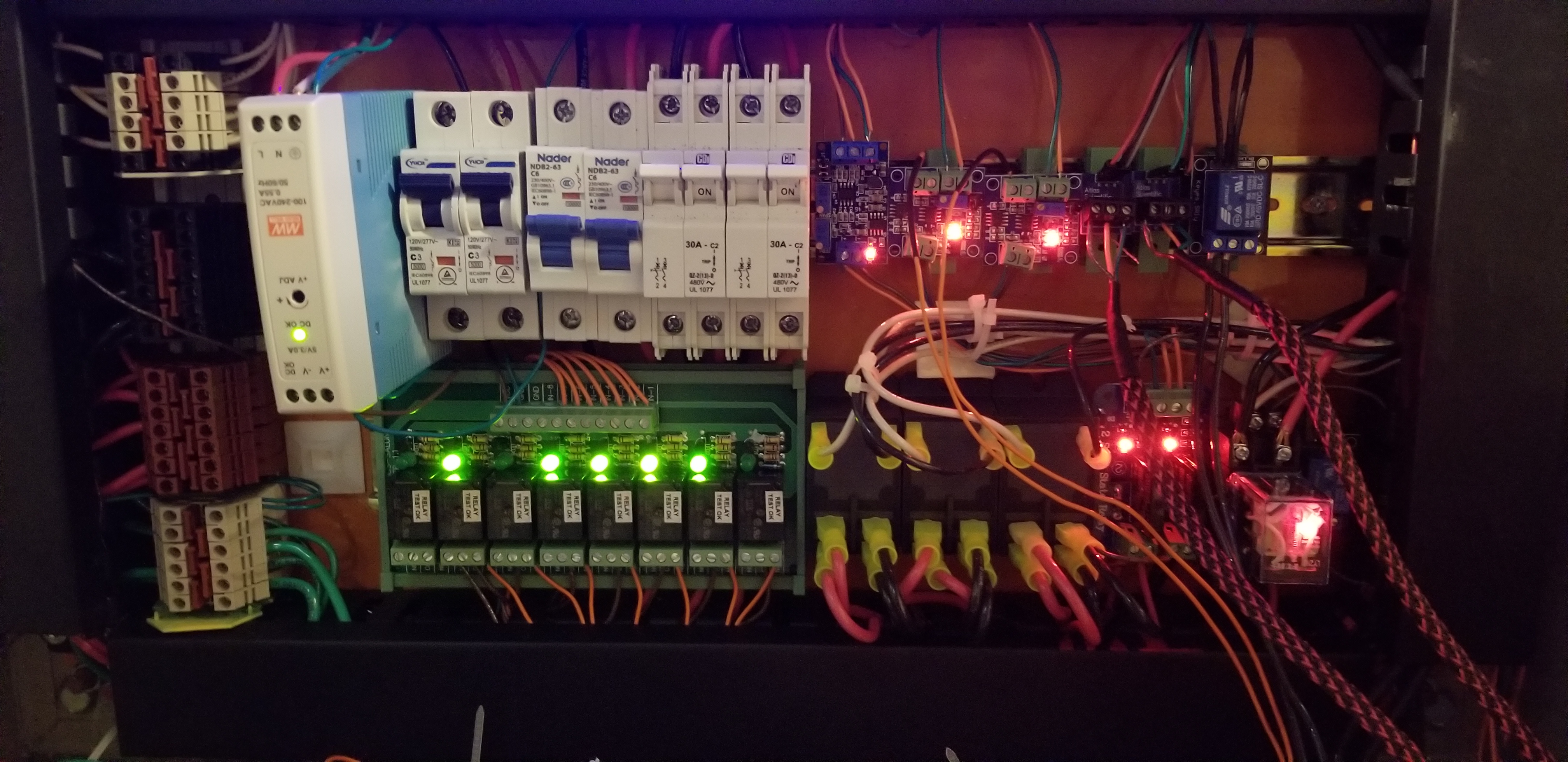

Otherwise, this build was based off of the 30amp 240v schematic off of brucontrol.com, but the more and more i read, researched, and understood about the hardware side of the build. The more I deviated from the schematic.

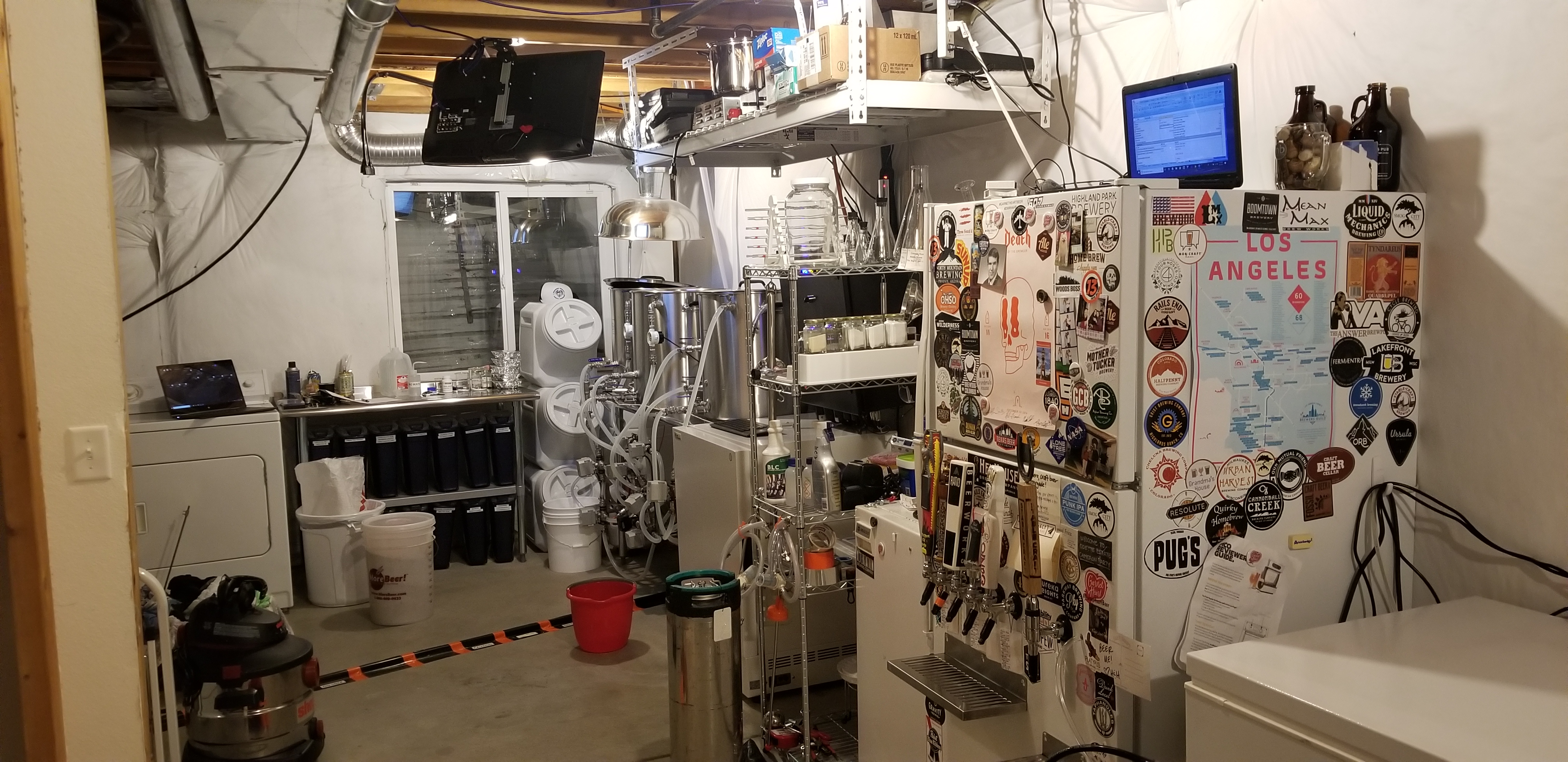

I have in the past build a Kal Clone and can say the best part about Brucontrol is its ability to expand functions.

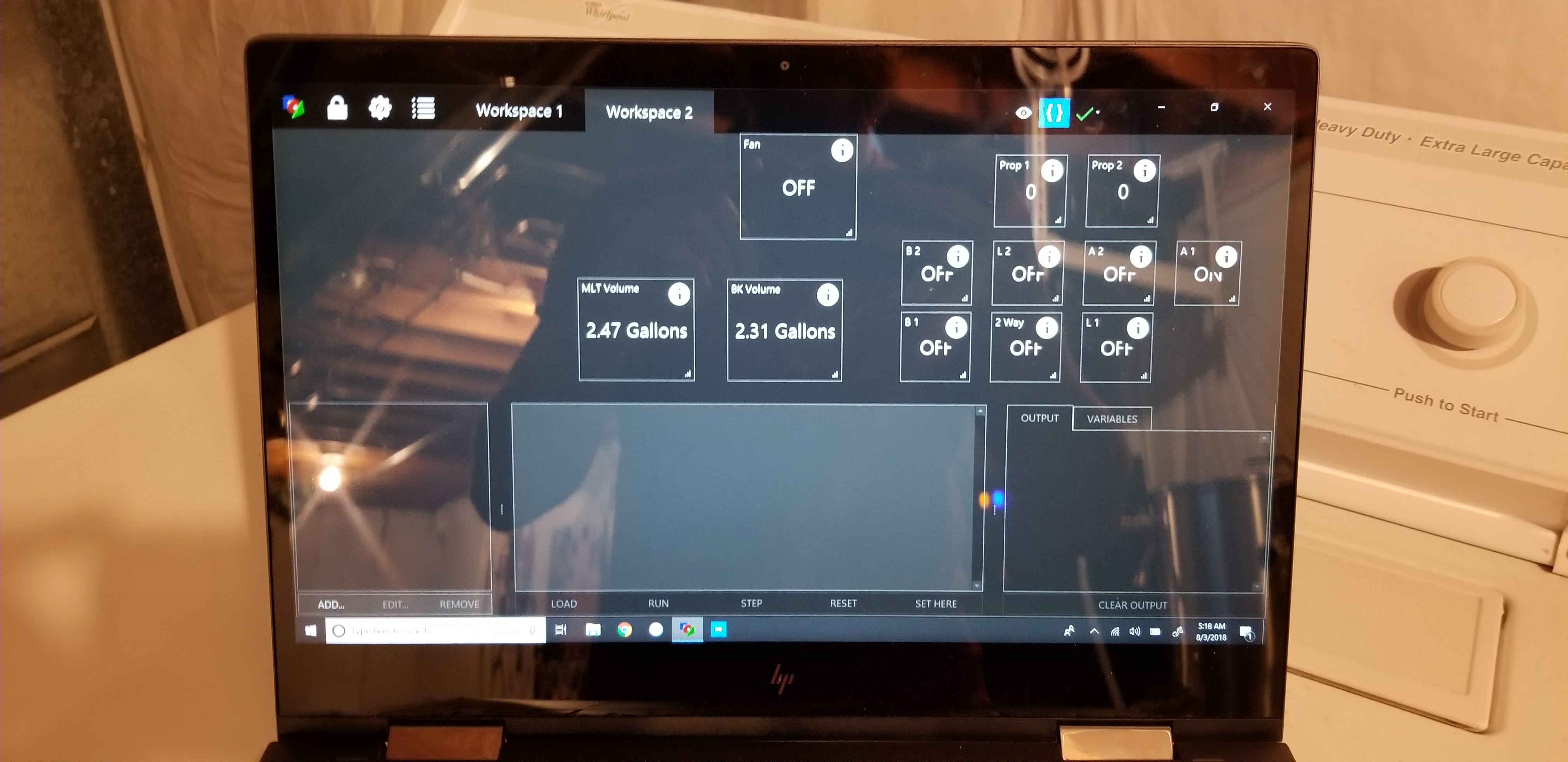

Still some improvements to be made in my system. I want to expand to some sort of auto grain in. (i am currently working on a rotating mash arm). Need to add a dosing pump for lactic acid additions. Need to work on a way to auto Hop the boil. lastly I am going to rethink how my valve are laid out and redesign it.

Pros:

Cons:

Still currently in development is my scripting, as life seems to get in the way of me actually sitting down and prototyping the script i want to use.

So far, I have put 2 x 12 gallon batches through the new panel. A Gose and a Bo Pils and as far as I can tell the software does its job incredibly well.

I have a few more kinks to work out here and there as my process improves due to the addition of new valves and electrical wires, but overall I am extremely happy.

Otherwise, this build was based off of the 30amp 240v schematic off of brucontrol.com, but the more and more i read, researched, and understood about the hardware side of the build. The more I deviated from the schematic.

I have in the past build a Kal Clone and can say the best part about Brucontrol is its ability to expand functions.

Still some improvements to be made in my system. I want to expand to some sort of auto grain in. (i am currently working on a rotating mash arm). Need to add a dosing pump for lactic acid additions. Need to work on a way to auto Hop the boil. lastly I am going to rethink how my valve are laid out and redesign it.

Pros:

- I no long have to be in my basement to monitor my brew day

- I actually have time to sit down and eat breakfast while brewing

- I learned a lot about the world of arduino and electronics in general

- I can concentrate more on wort quality now than the brewing process

- BruControl is way less expensive than buying PIDs

- BrunDogs customer support is out of this world good. (response within an hour or less)

- Interface is sleek, I havent felt the need to change any of the default look

Cons:

- The upgrade to a brewery build to make the full use of Brucontrol is quite expensive. This is not a con of the program, but a barrier to enter.

- I wish there was a reset button on the flow meter totalizer (kind of like how there is one on the timers), but its easy to script a button on the program to reset it that way.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)