@BrunDog and all

During the tests today (45O version of FW + build 15), I was able to "kill" MEGA so it wouldn't respond anymore. I don't think it's EMI this time. As this was dry run.

I have a script which I start during the strike step (or mashing) which is monitoring flow rate trough RIMS. If flow is less than 2L/s I disable the heater Duty Cycle or PID which ever is currently active, and stop brewing process with a message and waiting for user interaction "wait and press button when ready"

If the flow is ok again, I enable whatever heater was active before that.

Note: elements which I am enabling are connected to the same data output (RIMS DUTY Cycle and RIMS PID) as I have one heater. If one is enabled the other one is disabled. BC is also taking care that both can't be enabled in the same time.

The reason for using both is - I use duty cycle to heat faster until 2 deg below the target, then I switch to PID to maintain.

Unsure if that's important.

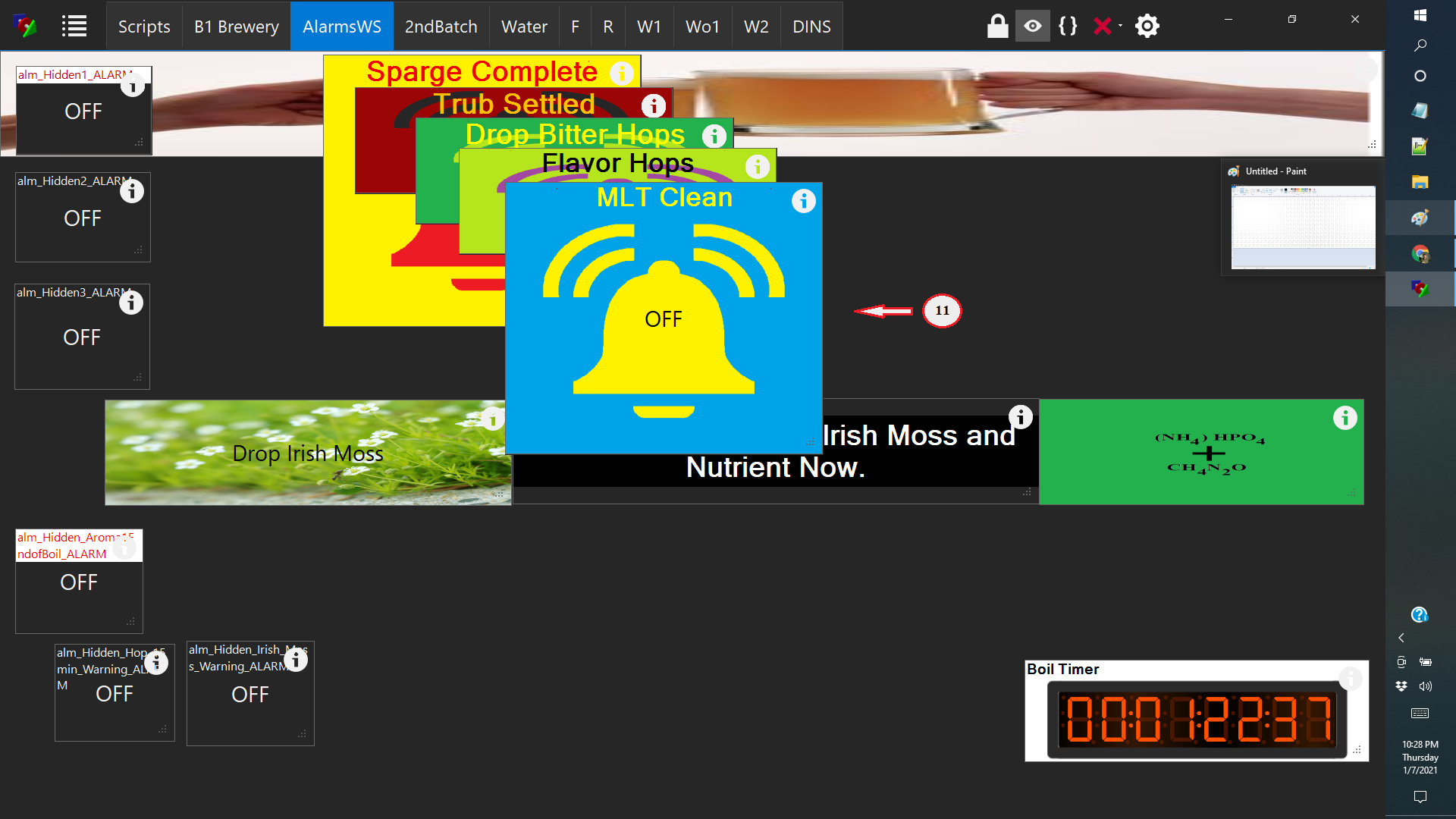

View attachment 713300

During testing, I was able to consistently to kill MEGA.

Attaching logs:

- one disconnect happened at 12:06 after:

12:06:26.657: Tx: /13!29,1,0,0,-1,0?2?100?208?209?48?49?102?103?3

-2nd disconnect happened at 12:20 after:

12:20:19.481: Tx: ?2?100?208?209?29?48?102?103?3

EDIT: -3rd disconnect at 13:18after :

13:18:39.959: Tx: !29,1,0,0,-1,0?2?100?208?209?48?49?102?103?3

Anyhow, I have no clue why how I am able to do it.

Maybe you would have idea why this happens when you look at the logs.

Thank you

Please email us a copy of the configuration file and a description of what is on each port.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)