aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

Does the interface (esp32??) mount to the lid? 6 x 6 x 2 enclosure?clearwaterbrewer said:

Last edited:

Does the interface (esp32??) mount to the lid? 6 x 6 x 2 enclosure?clearwaterbrewer said:

What solder terminals are used on the RP-3? Need to replace a stripped out terminal

I have something similar going on with my esp32s, haven't gotten around to chasing up a fix myself or details to pass onto you yet though. It first started six months ago when I was testing, so probably an earlier firmware than 45N at the time, but that's what it's on now. I'll try to chase up some details over the next few days when I can spend some time in the shed.This is something new? Or after an upgrade?

This is something new? Or after an upgrade?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Ok so to clarify, The ESP32 can power the RP-3 directly using one of the 3.3V pins?If you connect the RP-3 to an ESP32, you need to use 3.3V, as that is the max voltage any of it's pins can accept.

I have 2 RP-3 connected to a single ESP32 this way, and sometimes on power-up I have to disconnect one before the ESP becomes reachable, then connect it and all works fine... the ESP32 is powered via USB, and I need to ensure I am using the 3.3v pin... multiple other ESP32 variants with single RP-3 are working fine...Ok so to clarify, The ESP32 can power the RP-3 directly using one of the 3.3V pins?

Could you post a Part's List and where you got them?

LAN Port?Pretty nice mini-PC. Should run BC well (and other apps) for $179 to your door (not an affiliate link): https://www.amazon.com/dp/B08KCZPQ3P.

Do you mean Ethernet? That’s a good point and I had to look. You are right... no built in port. Easily fixed with a USB dongle though.

What do you think of this for running BruControl?

https://www.amazon.com/CHUWI-Gemini...c_13896591011_t1_B07THWPRS1?tag=forumyield-20

Not sure if this is the place for this, but I just recently bought a copy of BC. I was a former Craftbeerpi user. My 3 bbl setup has just basic PID control and I'd like to add more user friendly options. I have the basics/ manual portion of BC down. I think it may take me some time to get the scripting down. If i could just get an example of attaching a switch and LED to say a pump using PWM or to a PID this would help a lot. I need something practical that I can use and branch off of. ANY help would be greatly appreciated. I'm assuming said script is fairly short and sweet??

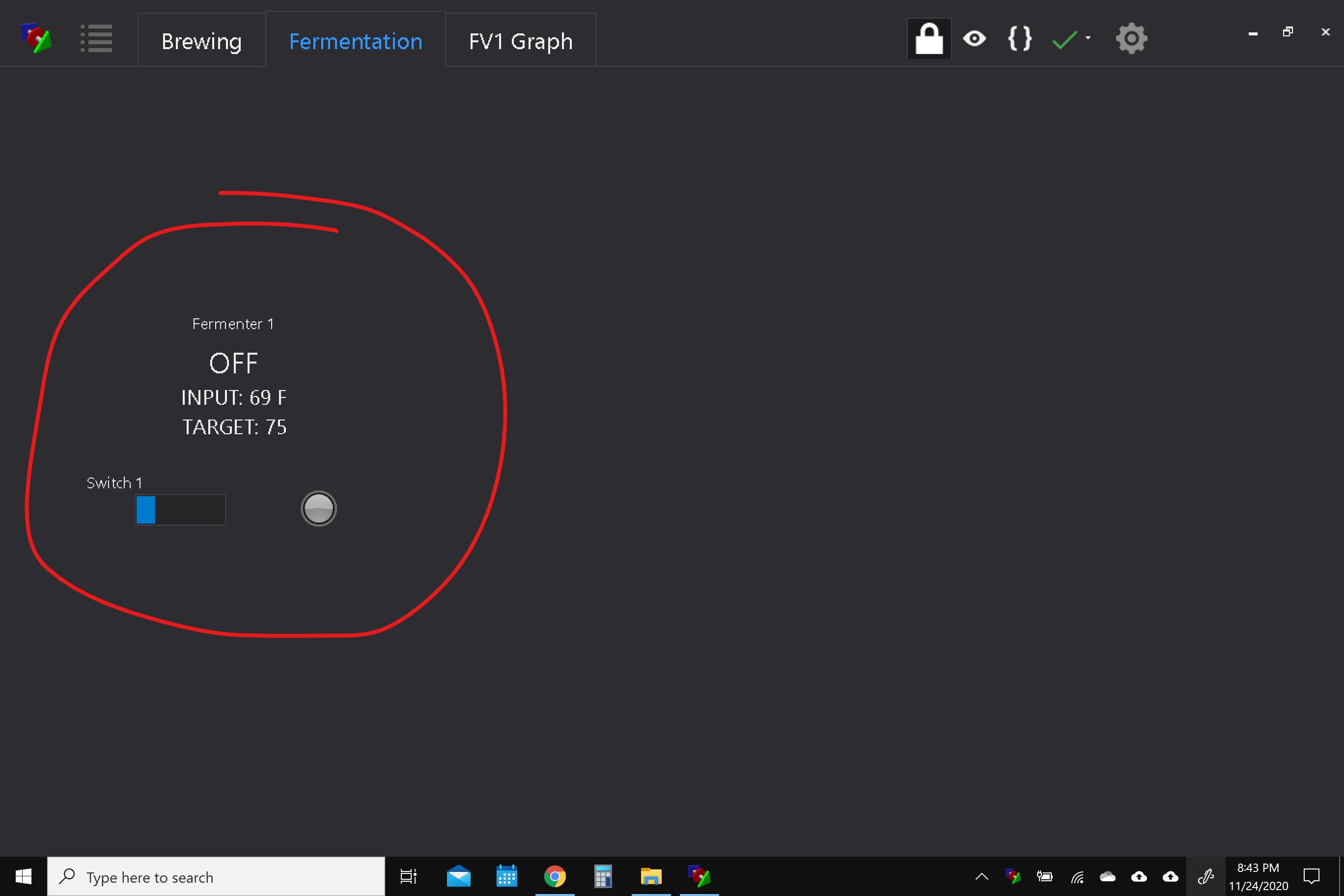

So I have created a PID to operate elements, Hysteresis for my fermentation and a 0 to 100 PWM for pumps. I know I can Enable and turn them off/down from the control, but I really like having an "on/off" switch with LED indicator for my elements and pumps. I like to set my pumps to say 25% and just turn an and off at that percent and then adjust as needed. Plus it's a faster way to disable the element or pump if needed. For fermentation id like the switch to turn off the Hysteresis so that my solenoid doesn't kick on say when I'm running CIP. This way I wouldn't have to turn the temp up or disable the PID it's self (which is totally doable, but I like the simplicity of "on/off" switch). So I am hoping with one script example I can modify it to do these similar things and get my feet wet a bit on this whole scripting thing. Let me know if this makes sense? I've added an example of the fermentation setup up and how I would like to link the switch to the temp control with an LED indicator. It would then be similar to that of the pump control and element PID.I can try help, but I'm not clear on what you have so far and what you are looking to do. Did you create a PID Device Element to control your device? Is that working manually?

Now, what do you want to do? You don't need a switch to control it, because you can control it directly in the workspace. Perhaps more details and/or pics could give us some direction. Thanks!

I have a Digital Input Element on a Mega that is not wired yet to any equipment. It is cycling "On" and "Off". There are no scripts running. Is this because I do not have anything wired to the Port?

So I have created a PID to operate elements, Hysteresis for my fermentation and a 0 to 100 PWM for pumps. I know I can Enable and turn them off/down from the control, but I really like having an "on/off" switch with LED indicator for my elements and pumps. I like to set my pumps to say 25% and just turn an and off at that percent and then adjust as needed. Plus it's a faster way to disable the element or pump if needed. For fermentation id like the switch to turn off the Hysteresis so that my solenoid doesn't kick on say when I'm running CIP. This way I wouldn't have to turn the temp up or disable the PID it's self (which is totally doable, but I like the simplicity of "on/off" switch). So I am hoping with one script example I can modify it to do these similar things and get my feet wet a bit on this whole scripting thing. Let me know if this makes sense? I've added an example of the fermentation setup up and how I would like to link the switch to the temp control with an LED indicator. It would then be similar to that of the pump control and element PID.View attachment 707787

[setup]

new bool toggle

toggle = false

[loop]

if "Switch 1" state == true

if toggle == true

"Fermenter 1" enabled = true

toggle = false

endif

else

"Fermenter 1" enabled = false

toggle = true

endif

sleep 100

goto loop[loop]

if "Switch 1" state == true

"Fermenter 1" enabled = true

else

"Fermenter 1" enabled = false

endif

sleep 100

goto loopthat would help already a lot. thxNo, sorry. We need to make an element copy function!

Thank you that works great, I was able to apply this to all the elements that I wanted to be able to turn on and off? I did try to incorporate the LED indicator with no luck. I tried both a global and inspector. Global being boolean (true/false) and inspector having the ability to add a script to it but was not successful? Any ideas?Gotcha... that's easy. Here is a script example of the switch controlling the fermenter element:

Code:[setup] new bool toggle toggle = false [loop] if "Switch 1" state == true if toggle == true "Fermenter 1" enabled = true toggle = false endif else "Fermenter 1" enabled = false toggle = true endif sleep 100 goto loop

I used a toggle flag to limit the repeat enablement of the fermenter element, though in truth BruControl will not resend to repeat command to the device element, so it isn't really necessary.

Code:[loop] if "Switch 1" state == true "Fermenter 1" enabled = true else "Fermenter 1" enabled = false endif sleep 100 goto loop

Update: Appears I just needed another go at it! I was able to use global with led. My problem was I was not "enabling" the element rather than changing the "value" of it to true/false. Makes sense, I just couldn't find the term I needed to communicate this to the element but some digging got it done.Thank you that works great, I was able to apply this to all the elements that I wanted to be able to turn on and off? I did try to incorporate the LED indicator with no luck. I tried both a global and inspector. Global being boolean (true/false) and inspector having the ability to add a script to it but was not successful? Any ideas?

I watched a review on this and it actually wasn't bad or a basic 150 dollar laptop. The storage and Ram are also upgradable!

I did report this. PITA!Not sure if this has been mentioned yet, but I just upgraded to v1.1.0.9 and see all the new element enable switches. It doesn't look like there is an option to disable that from the default element setup. Is the only way to do this currently by disabling it in each element? I've got a lot of elements.

I have a Mega that is not wired so I can create "Elements" that act like the real thing. I can control a different real Element on a different Workspace with my "Psuedo" Element, with the exact look and feel of the real Element.Update: Appears I just needed another go at it! I was able to use global with led. My problem was I was not "enabling" the element rather than changing the "value" of it to true/false. Makes sense, I just couldn't find the term I needed to communicate this to the element but some digging got it done.

Thanks again for all the help. Feels good to figure it out on my own lol