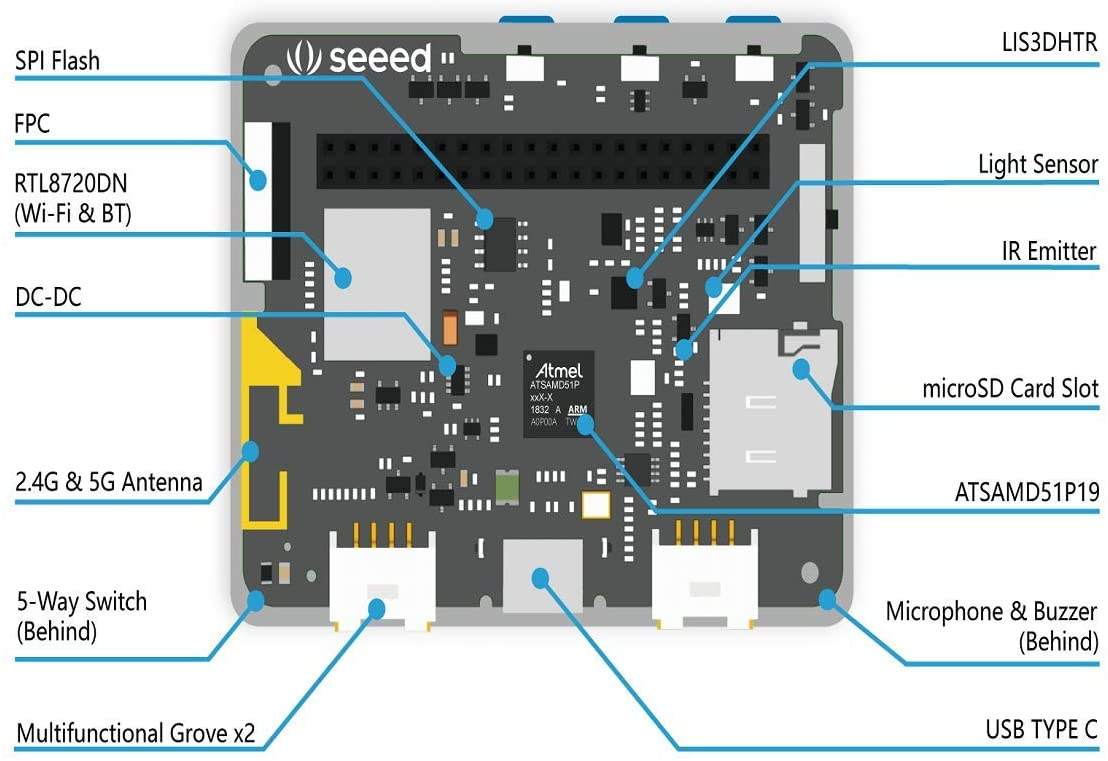

interesting, just saw this seeed studio Wio Terminal: ATSAMD51 Core with BLE 5.0 & Wi-Fi 2.4G/5G Dev Board on amazon for $38.99

shorter link to device mentioned, https://www.amazon.com/dp/B077WTTTFH/Would I be able to use something like this with Brucontrol to drive a servo motor? I have a HopsBoss that I haven’t been able to get up and running with a NodeMCU and the Data Exchange framework. I’m curious about other options to try.

Esp8266 motor driver shield

I think either will 'run a motor' from control in BruControl, but you will be in charge of positioning accuracy...

I think either will 'run a motor' from control in BruControl, but you will be in charge of positioning accuracy...

Hi all - I’ve been reading through the thread and while I’m interested in moving platforms, it is a bit overwhelming for me. I’m wondering if anyone has replaced a Pi 3b+ running CBPI 3 in a Hosehead 5 BC to an ESP 32 running brucontrol. It seems like a fairly easy switch, but I don’t know what I don’t know. I’m fed up w cbpi, but the other components in the hosehead are solid and seems like they could be repurposed.

I moved from a BCS to BruControl with no hiccups other than the learning curve for BruControl. l am not familiar with the Hosehead box, but since it probably uses SSR or Proportional Controllers to activate the Elements, it would likely be fairly straight forward to convert. You may have to replace some of the control wiring and possibly the SSR to Proportional Controllers if you need true PWM or True PID, although for Brewing Beer Hysteresis or Duty Cycle are good enough.Hi all - I’ve been reading through the thread and while I’m interested in moving platforms, it is a bit overwhelming for me. I’m wondering if anyone has replaced a Pi 3b+ running CBPI 3 in a Hosehead 5 BC to an ESP 32 running brucontrol. It seems like a fairly easy switch, but I don’t know what I don’t know. I’m fed up w cbpi, but the other components in the hosehead are solid and seems like they could be repurposed.

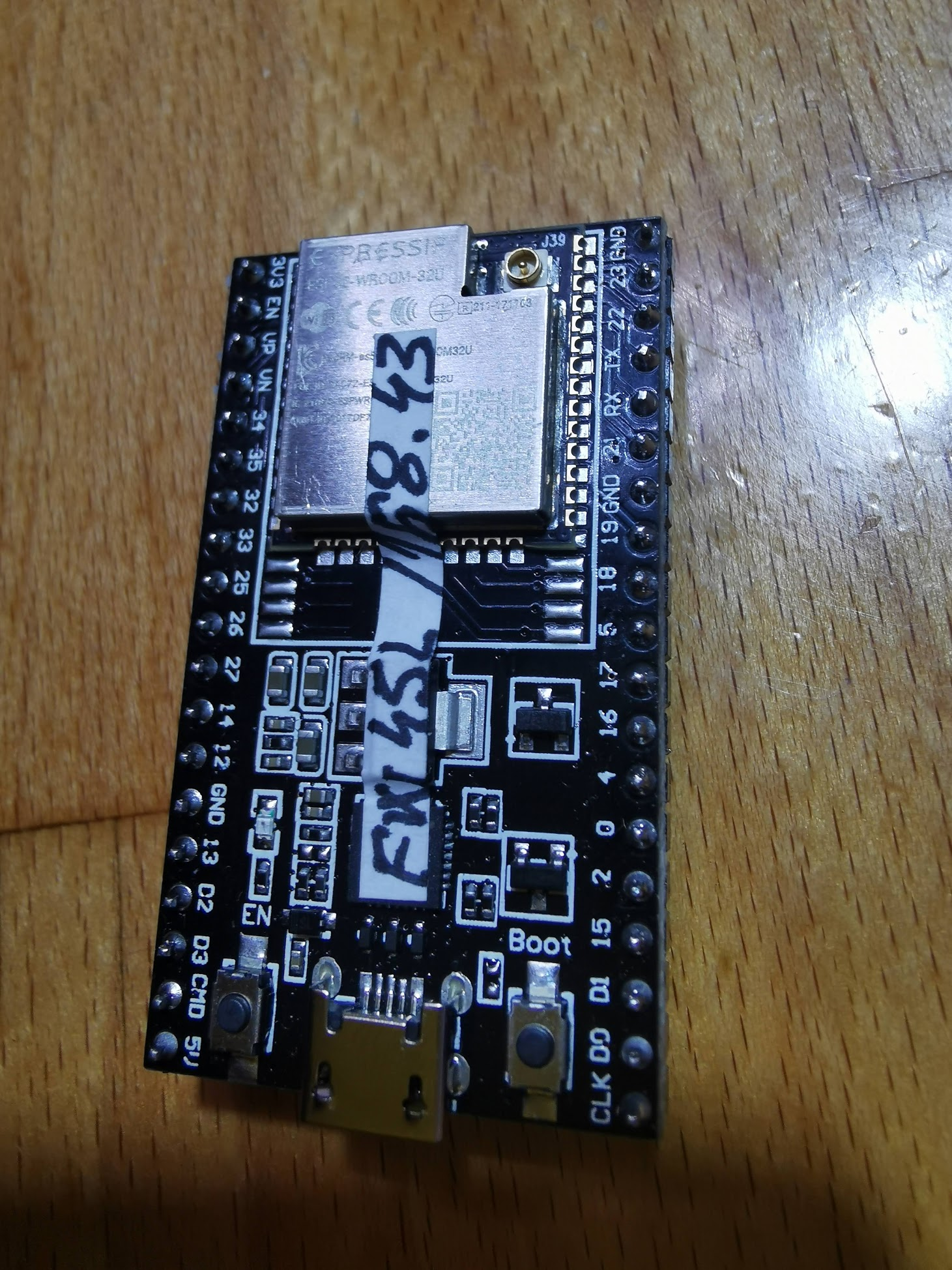

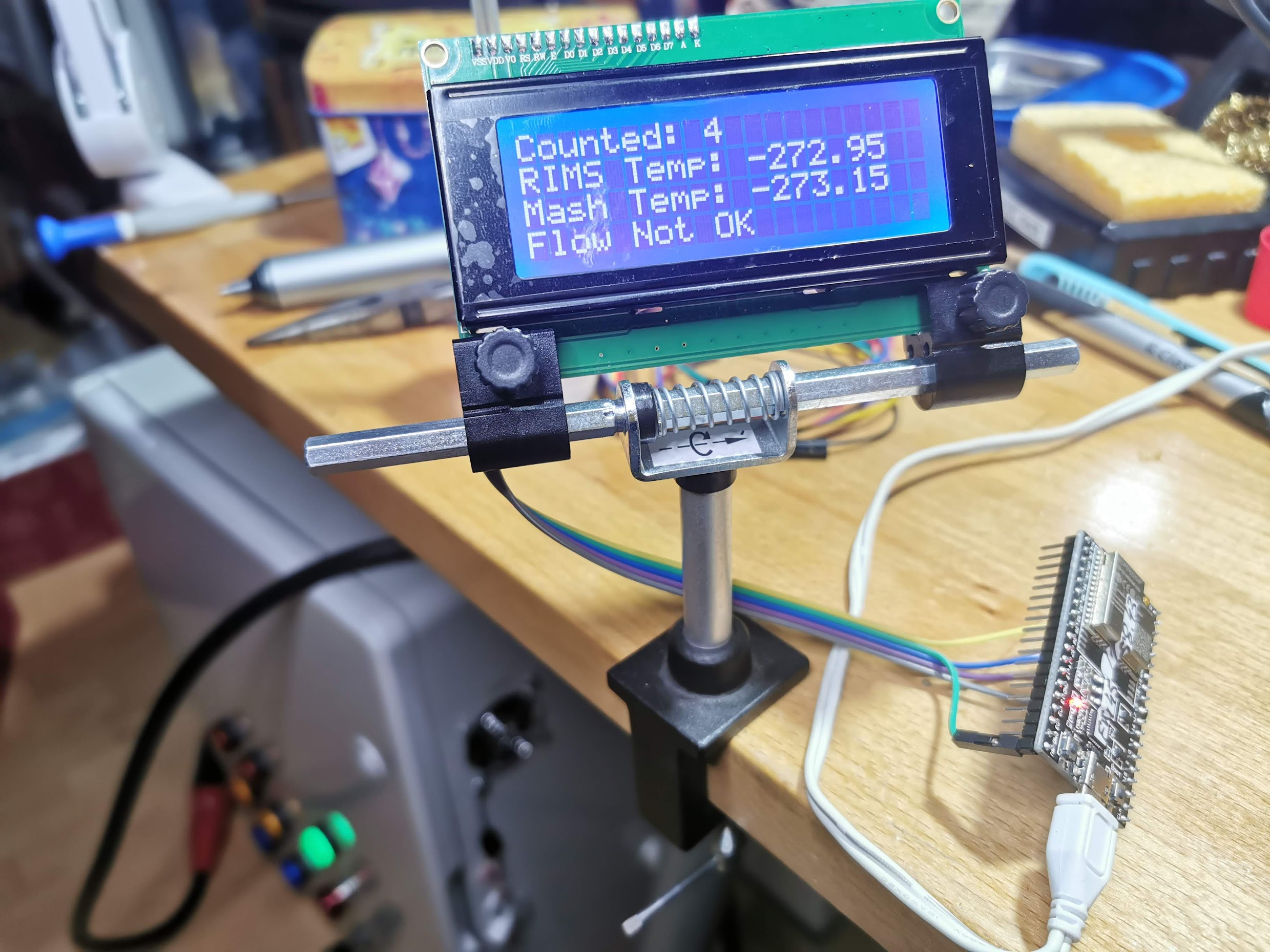

Is it possible to connect Adafruit #292 LCD backpack / 20x4 character LCD to esp32-WROOM-32U (38 pin) module ?

Noob question where are SDA and SCL ?

This is what I found on the net.

SDA default is GPIO 21 SCL default is GPIO 22

View attachment 709509

thanks will give it a tryI don’t think we tested it with ESP32, but those pins are correct and it *should* work. If you test it please report back. We can test if needed but I need to check to see if we have the LCD on hand.

I don’t think we tested it with ESP32, but those pins are correct and it *should* work. If you test it please report back. We can test if needed but I need to check to see if we have the LCD on hand.

Coming from CBPI3 world here, so what comes to my mind as inexpensive and simple:Hi all. Hoping to get the next beta update, including the new profile element uploaded at the end of this week.

in the meantime, I was exchanging ideas for a inexpensive / universal interface board with another user and thought I’d open up up for feedback and requests. Current thinking:

Thoughts? Ideas? Desires? Stretch goals?

- Headers to plug in a micro... could be Feather format or ESP32 development board

- 4x RTD amplifiers. Thinking on-board but could be headers for swaps and $ reductions

- Screw terminals for I/O connectivity

- Jumpers for pull-ups for I2C and 1-wire

- High current drivers to drive DC devices / relays / valves / solenoids / pumps. Maybe 4 or 8 channels

- Power supply? Could be DC-DC or if we wanna get crazy 120/240 VAC universal input

- Mount. Could be DIN rail carrier or other mini-enclosure.

I would suggest dip switches over jumpers. Most people don't have a supply of jumpers and they can get lost.

When I had the BCS, I wrote some HTML to display something like this data on a large screen (40 inch). That way, I could see it from across the room. Hopefully with Node Red, I will try it again once I get my Brewery up again.Nice! Thanks for testing and reporting back. I personally prefer the info on the workspace but these are great when you need quick data available elsewhere.

Hi all. Hoping to get the next beta update, including the new profile element uploaded at the end of this week.

in the meantime, I was exchanging ideas for a inexpensive / universal interface board with another user and thought I’d open up up for feedback and requests. Current thinking:

Thoughts? Ideas? Desires? Stretch goals?

- Headers to plug in a micro... could be Feather format or ESP32 development board

- 4x RTD amplifiers. Thinking on-board but could be headers for swaps and $ reductions

- Screw terminals for I/O connectivity

- Jumpers for pull-ups for I2C and 1-wire

- High current drivers to drive DC devices / relays / valves / solenoids / pumps. Maybe 4 or 8 channels

- Power supply? Could be DC-DC or if we wanna get crazy 120/240 VAC universal input

- Mount. Could be DIN rail carrier or other mini-enclosure.

When I had the BCS, I wrote some HTML to display something like this data on a large screen (40 inch). That way, I could see it from across the room. Hopefully with Node Red, I will try it again once I get my Brewery up again.

What about an add-on onewire shield?Good point - 1-wire is kinda a PITA to terminate multiple probes. Twisting copper to jam into one block isn’t a good approach. Perhaps we use a three-tiered block set, though they tend to be pricy for what you get.

Possible. Would be a lot of empty copper though since 1W only needs a resistor and some terminals.What about an add-on onewire shield?

You who can solder can worry about copper. Ease of connection for me! I have stayed away from 0ne Wire due to the "numbering" in replacing a probe. The are certainly accurate enough for most hot side processes and very little $.Possible. Would be a lot of empty copper though since 1W only needs a resistor and some terminals.

Current thinking:

Thoughts? Ideas? Desires? Stretch goals?

- Headers to plug in a micro... could be Feather format or ESP32 development board

- 4x RTD amplifiers. Thinking on-board but could be headers for swaps and $ reductions

- Screw terminals for I/O connectivity

- Jumpers for pull-ups for I2C and 1-wire

- High current drivers to drive DC devices / relays / valves / solenoids / pumps. Maybe 4 or 8 channels

- Power supply? Could be DC-DC or if we wanna get crazy 120/240 VAC universal input

- Mount. Could be DIN rail carrier or other mini-enclosure.

You says it better than me. Good points made!

- ESP is super inexpensive and ubiquitous (I love the Wemos D32pro with tft port, but they could stop making it tomorrow...)

- RTD amp boards are kinda bulky, and require mods, on-board wired for 3-wire is my preference. 4 needed, 8 is overkill

- Screw terminals for rtd and 1-wire should be tiny, not the ginormous ones on the RP-3

- jumpers are great, anyone that has a sunfounder relay board or worked on x86 PC's likely has dozens if not, you can make one with a chunk of stacking header, or visit a grey-haired neighbor

- 4 channels if hi-power seems fine, buy more units if you need more...

- powering:

- on-board ESP32 usb if no hi-power

- USB on-board with ample power supply if using hi-power

- if 120/240VAC is wanted, maybe leave the open holes for the possibility of the user adding a Hi-link HLK-PM03 AC-DC 220V to 3.3V Step Down Buck Isolated Power Supply Module and some screw headers for AC?

- Mounting - din rail joles liek RP-3, and add hole pattern matching the sonoff TH/Dual PCB dimesnions to mount in their inexpensive, $4 IP66 waterproof case

other comments...

- yes, ESP has lower number of GPIO, but BruControl can have dozens of these, unlike CBP3

- 1-wire should not have multiple connections at the interface, that is star pattern and is not what 1-wire is best at, let the user do that with terminal blocks or solder... try to get 1-wire users to make a chain, not a star....

I have 3 wire and 4 wire RTD Probes, so any RTD would need a jumper or DIP. I think screw shields are great but on your UNI interfaces, they are not open enough in my mind. Any screw shields should be easy to access when installed in an enclosure. While smaller boards are better, RTDs integrated with an Interface would be great. My issue with the ESP-32 is the number of GPIO and lack of Ethernet.

what is the accuracy drop of using a 4-wire as a three wire? 3 to 2 is pretty big, but 4-3 is not that big right? 4-wire seem to be very uncommon now as far as what I see out there... and the wiring change is not really like one jumper, it is like three per RTD. I think 4-wire are more used in Laboratory and NIST-calibration type environments here is a doc: https://reotemp.com/wp-content/uploads/2015/11/TB3-4WIRE-06143-Wirevs4-WireRTD.pdf

The UniShields ... Hear you on access, and we had to make trade-offs, but honestly once you have it set up, you shouldn't need to access anything underneath the shield or on the base.

Edit: I wish we could see a micro with a common form factor that supports that many I/O!

I am pouring concrete this next week and have added a large floor drain with a sloped floor under the Brewery. To me "Brewing is a wet process!"

I agree, unfortunately it’s not that easy. Another challenge beyond what I noted above is the mega has headers that run the perimeter of the board. This is highly inefficient use of space, and requires that anything stacked on top has to hold the circuits inside or outside that perimeter. For the driver board, to accommodate the number of I/O wanted, we needed the blank space.I am surprised no one has made a screw shield for a mega where it is easy to stack rather than the riser headers.