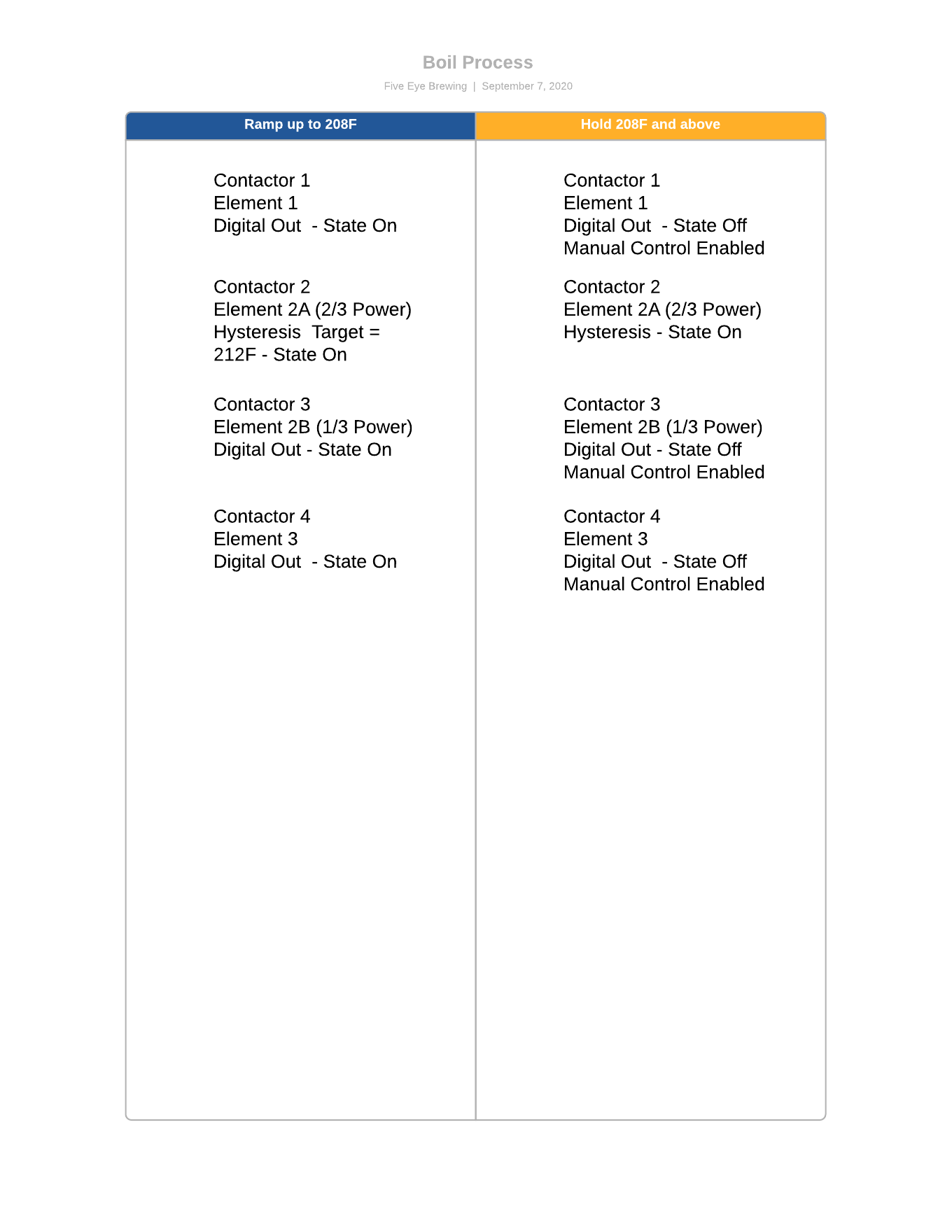

I currently have (4) 50a contactors controlling (3) 12kW heat elements, all in kettle.

Contactor 1 controls Element 1 via digital out

Contactor 2 controls Element 2 (1/3 Power) via digital out

Contactor 3 controls Element 2 (2/3 Power) via hysteresis

Contactor 4 controls Element 3 via digital out

If Contactor 2 and 3 are energized I get full power to Element 2.

During ramp phase, all elements will be 100% power. When I near boil over temps (208F or so), I plan to have BC automatically shutoff Element 1 and 3 and allow manual control of Element 2. Either 4kw, 8kw or 12kw (via Element 2), 16kw (adding Element 1 or 3).

I plan to have Contactor 3 controlled via hysteresis with a set point of 213. In script, I reference a boil offset global which defines a value of 208F. So if measured value is less than 208F, all contactors are live. If 208F is achieved, all Contactors are off except for Contactor 3 since 213 cannot be achieved. At a reduced power and no chance of boil over I want the operator to take over and begin turning on elements manually to achieve desired boil. This will likely be Contactor 2 for a total of 12kW. I thought a Low/High switch would be neat for Element 2. Need to actually boil our first batch to see if manual control of Element 1 or 3 is needed.

Looking for some improvements/ideas to the above.. I'm sure most of you are using SSRS at 5kW or so. Wanted to keep heat and component pricing down. I understand how much easier this would be with them!

View attachment 697295

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)