Piggles22

Active Member

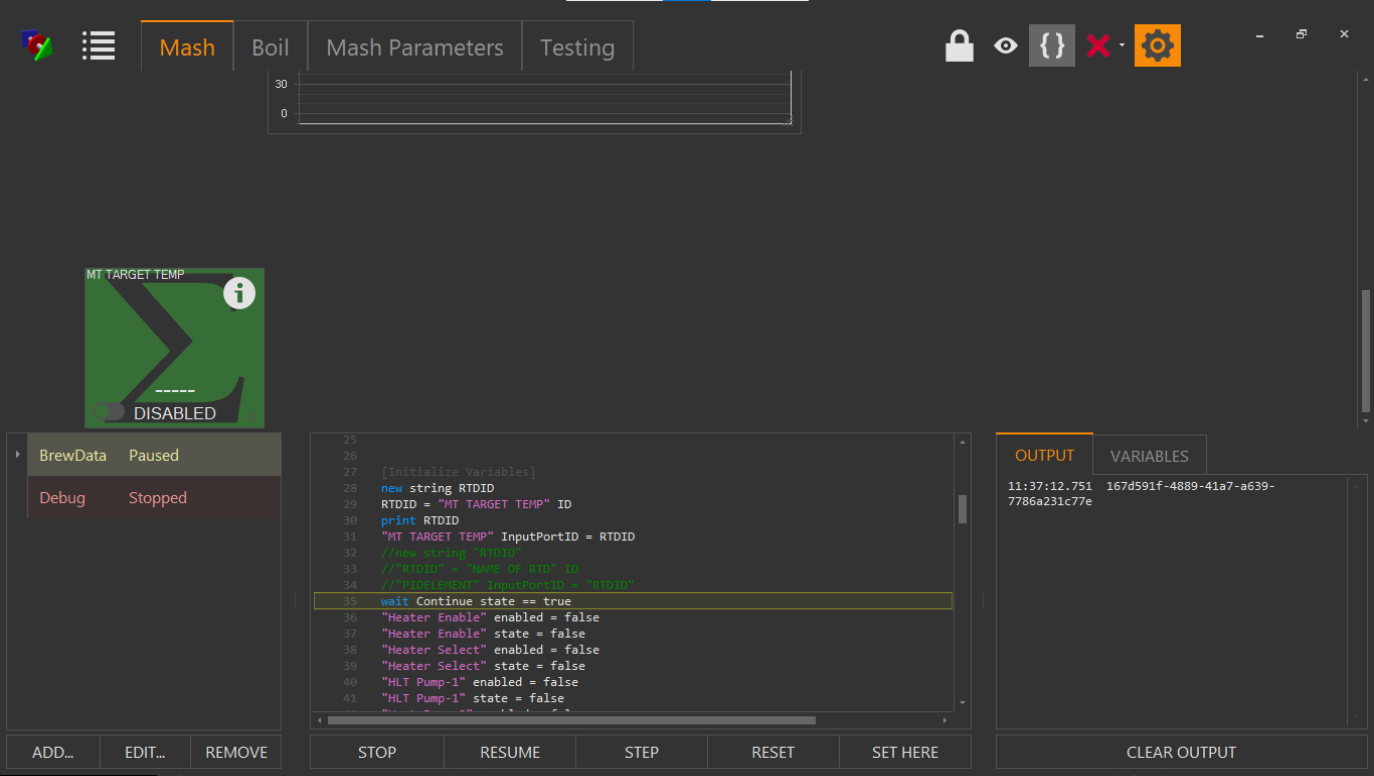

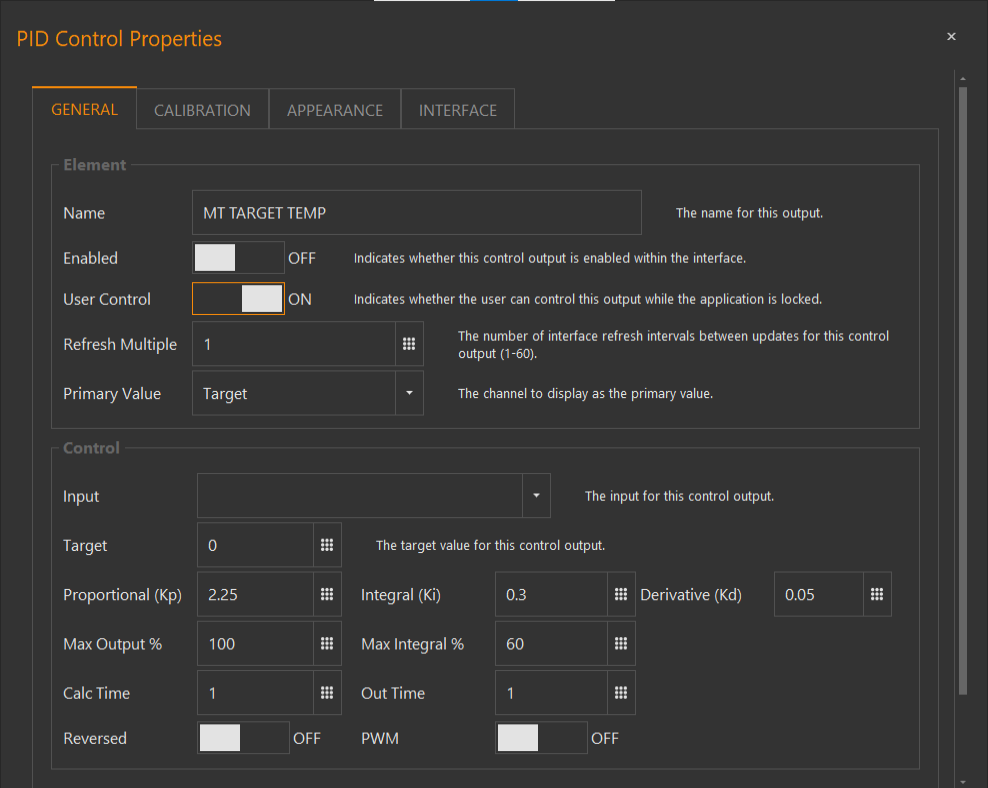

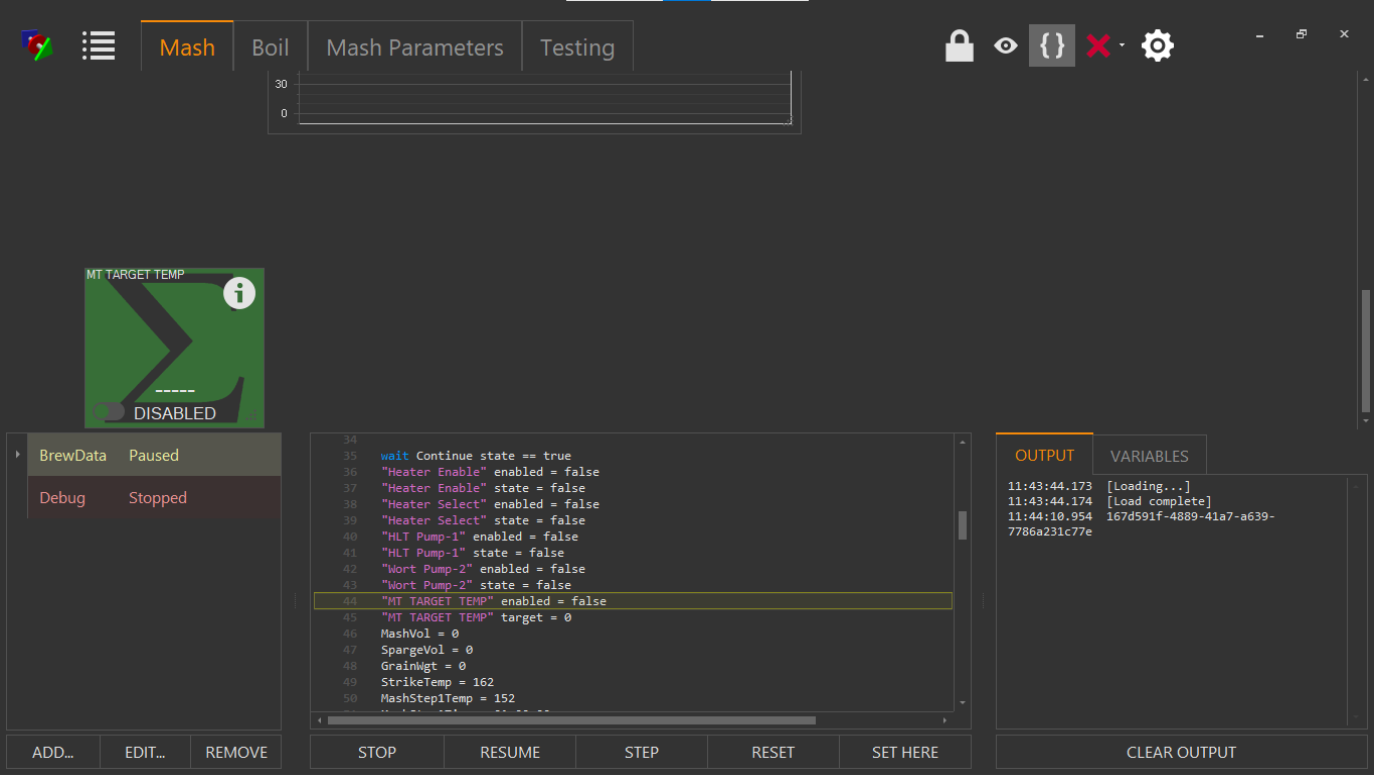

Plan on brewing on Sunday but will be entirely manual (no scripts - still working on that). A couple comments on added features:

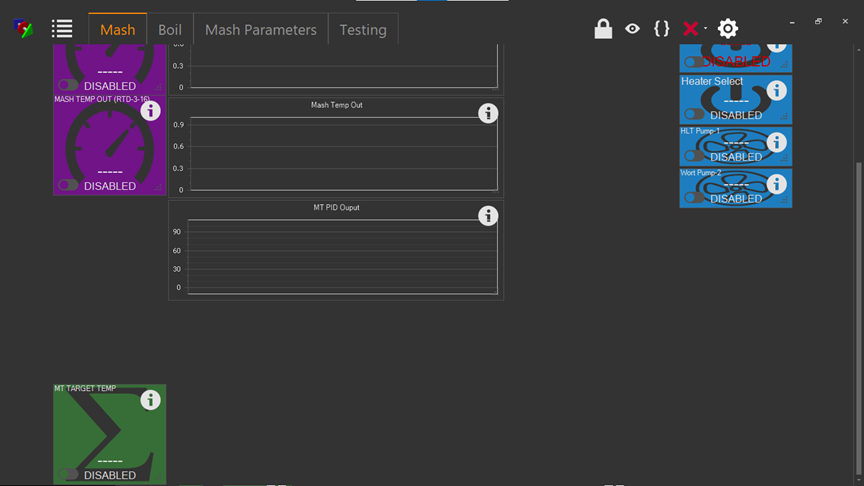

- Love the ability to enable/disable elements directly from the workspace

- The new line code (...\n...) for strings now works as documented

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)