helibrewer

Well-Known Member

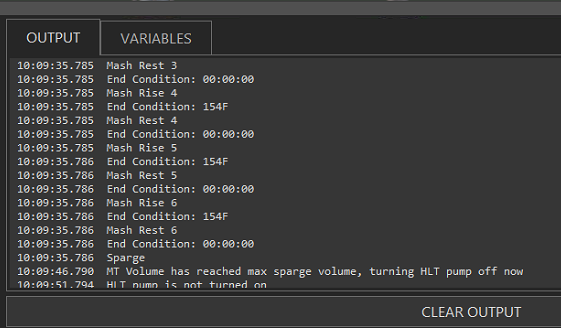

I understand what you're saying... don't use 6 timers for 6 steps instead use 6 global variables of type time and decrement their values based on the value of a central timer element. I'm just not sure that's the same thing as having 6 individual real time countdown timers.

The way I picture your layout operating is that at initialization, the 6 step temperatures are loaded and the countdown time for each step is loaded. At eh start of mashing, step one is executed until it's timer reaches zero, then the set point becomes the step 2 temperature and step 2's countdown timer begins. This repeats until all 6 steps are complete....is that the process?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)