Hello

@BrunDog. I perhaps need to test this more to better understand the boundaries but would it be possible for an inspector to be able to show output from more then one script at a time (i.e. not be forcefully linked to one)? I have an inspector used to show process notifications and I need to assign the inspector to look at a specific script. It would be more universally helpful if the inspector could show the chosen variable output from any script, not just the one specifically assigned script. At this point it is unclear how the inspector would handle output from a variable that is issued from a script that is called from another script (the calling script would be the one assigned to the inspector). Prompting and operator messaging is an important part of the robustness of any automated processing environment from my experience. It would be great if an inspector (or some other function not yet implemented) could show messages from any script without having to go in and reassign the inspector or work an inspector in a hidden/visible manner in a script. What are your thoughts on the current or future for BruControl and notification/prompting?

Use a

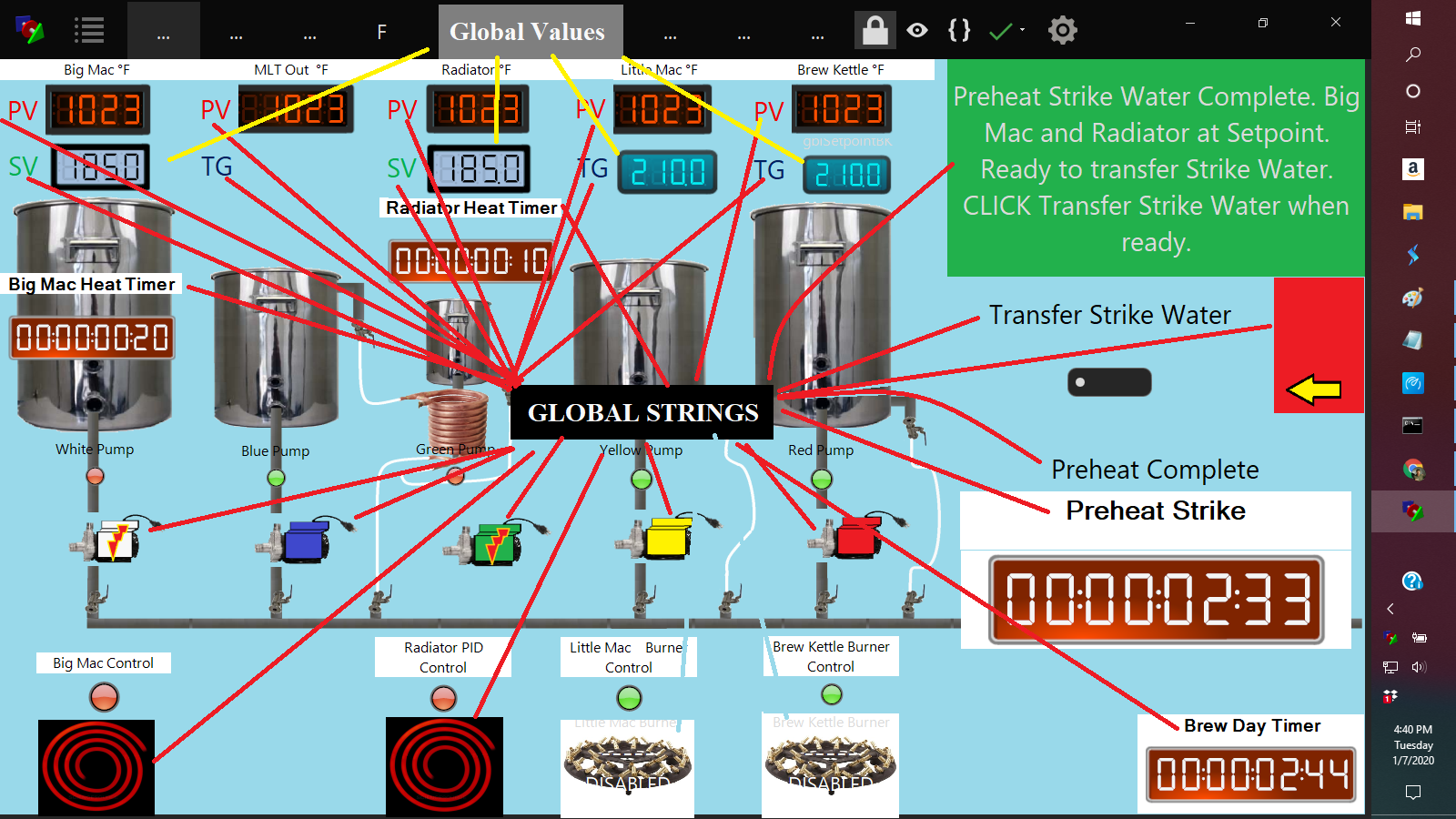

Global. It is independent of any scripts and can be anywhere on any workspace, hidden or not. I had the advantage that I came late to the game and basically never use an inspector. Anything you can do with an inspector you can do with a Global. Globals do not require a running script to display and you can easily change the value of a Global either manually or via a script. They are also static, meaning that if you close BruControl, you do not lose your variables if they are Globals. If you use Globals once for a variable, I doubt you would ever look back and use an inspector.

Inspector:

1. Requires the Inspector Element to be created.

2. Require Script to create the variable.

3. Requires Script to define the parameters of the variable (precision).

4. Requires a running script to display the Inspector.

5. Requires Script to change the Variable

6. Is dynamic and you lose the last value when you shutdown BruControl

7.

Is Script Dependent

Global:

1. Requires the Global Element to be created.

2. Does Not require Script to define the parameters of the variable (precision), but may be changed via script

3. Does Not require Script to be displayed, but you may use the visibility property to hide the Global Element

4. You may change a Global manually or via Script.

5. Is Static and the last value is retained if you shutdown BruControl. I use this to create recipes for Strike and Mash Temps and have a script that changes all the appropriate variables (Strike, Mash, Hop Drops) with a simple one button click for brews we repeat.

6.

Is independent of any Script or WorkspaceI.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)