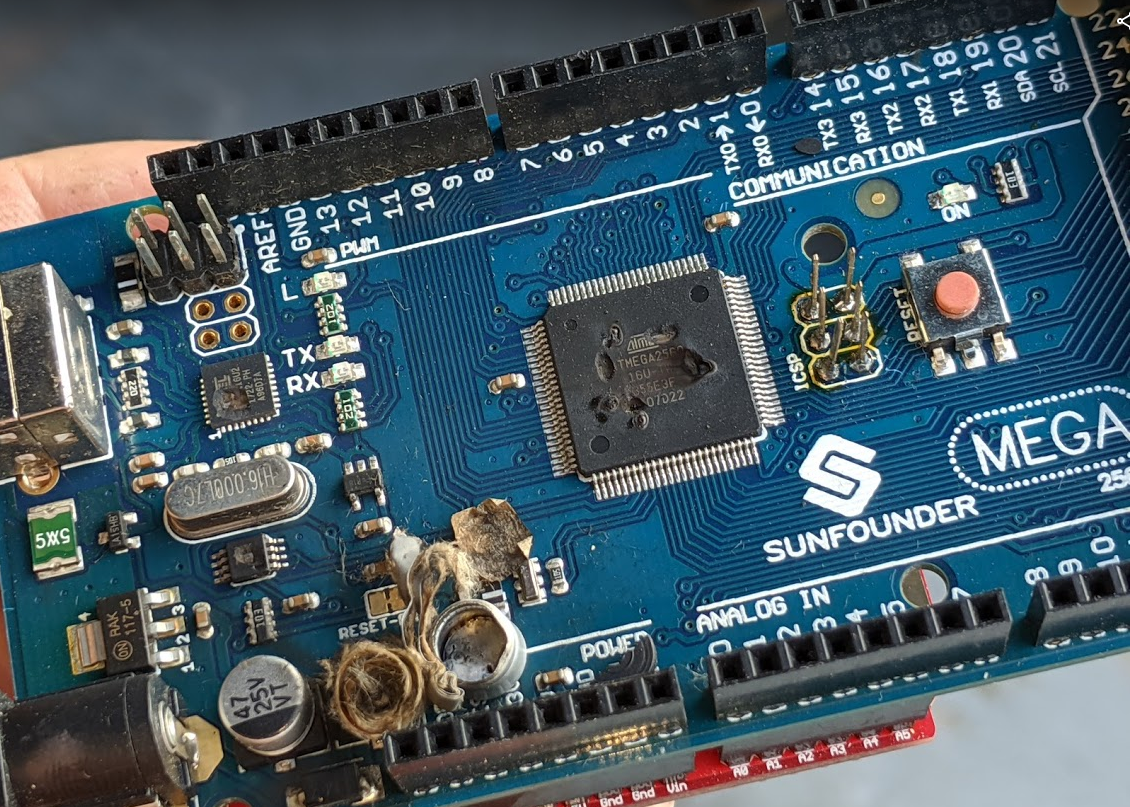

Fried a mega, was pulling out an unused contactor, and the base snagged the common wire of another contactor enough to tug it out and that common wire went straight into the power terminal and boom... I had the power off to the arduino, but this was a separate circuit breaker coming in for three phase to a 9kw element... the common wire was like a dart going for the double bullseye...

View attachment 650972

good news, I had a spare... bad news, It fried something on the screw shield, so ordered another one of those and will try to fix.. more good news, robotdyn boards are on sale for $33.66 today after a 10% amazon coupon, so will try one of those as a new spare, that price is awesome and de-soldering a jumper is less work than re-pinning a regular mega to get the w5500 board and screw shield to both work...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)