I've been wondering if the HED would help make whirlpool viable. Thanks for the info! I have the whirlpool arm but never used it.Yes! I have the heat exchanger disk(HED). Makes a noticable difference. Also have the whirlpool arm on a Brewzilla Gen 4. New Brewzilla user as of Feb 2024. Really like it a lot, especially cooking outside and the easy cleanup.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewzilla Gen4 Discussion/Tips Talk

- Thread starter stealthfixr

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The HED lifts the bottom plate by ~ 1/4"+ . Took a huge pile off the plate, mostly huddled in the center. Wort spills over at the edges and comes out cleaner. I use a funnel strainer - wort out of Brewzilla, into funnel then into fermenter. I was surprised how well it performed. 1st time. We will soon see if it is repeatable.I've been wondering if the HED would help make whirlpool viable. Thanks for the info! I have the whirlpool arm but never used it.

Yes. Makes a big difference because it raises the bottom plate above it to rest about 1/4 inch above the bottom holeDo you use the HED?

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

And another burnt cord. I've been unplugging from the wall first to prevent shorting. I'll go ahead and replace the plug and cord again but man this is crazy. Any ideas @KegLand ? This 2 and a half year old unit shouldnt be burning through cords like this. Theres another issue with a burned cord earlier in this thread. If there's any ideas, or tips, on how to prevent this from continuing to happen please let me know. Maybe I should look at hard wiring the cord to the board since it seems like the plug is a point of failure?

Heres the link to my previous failure

https://www.homebrewtalk.com/threads/brewzilla-gen4-discussion-tips-talk.702436/post-10221917

Heres the link to my previous failure

https://www.homebrewtalk.com/threads/brewzilla-gen4-discussion-tips-talk.702436/post-10221917

Last edited:

Well, that’s a little unnerving. Glad there was’t more damage. Hope KegLand can offer up some useful guidance.And another burnt cord. I've been unplugging from the wall first to prevent shorting. I'll go ahead and replace the plug and cord again but man this is crazy. Any ideas @KegLand ? This 2 and a half year old unit shouldnt be burning through cords like this. Theres another issue with a burned cord earlier in this thread. If there's any ideas, or tips, on how to prevent this from continuing to happen please let me know. Maybe I should look at hard wiring the cord to the board since it seems like the plug is a point of failure?

Heres the link to my previous failure

https://www.homebrewtalk.com/threads/brewzilla-gen4-discussion-tips-talk.702436/post-10221917

View attachment 853417

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

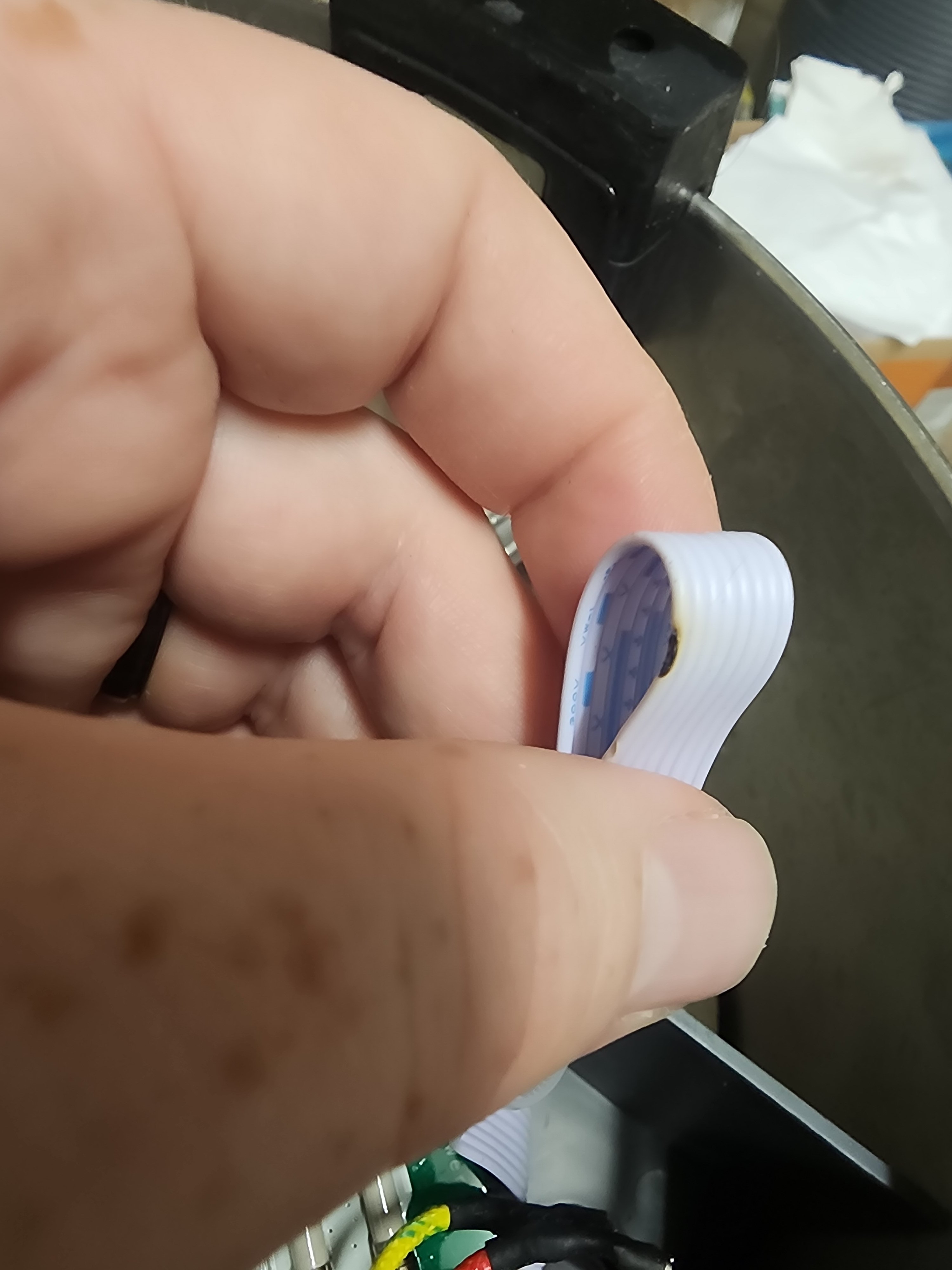

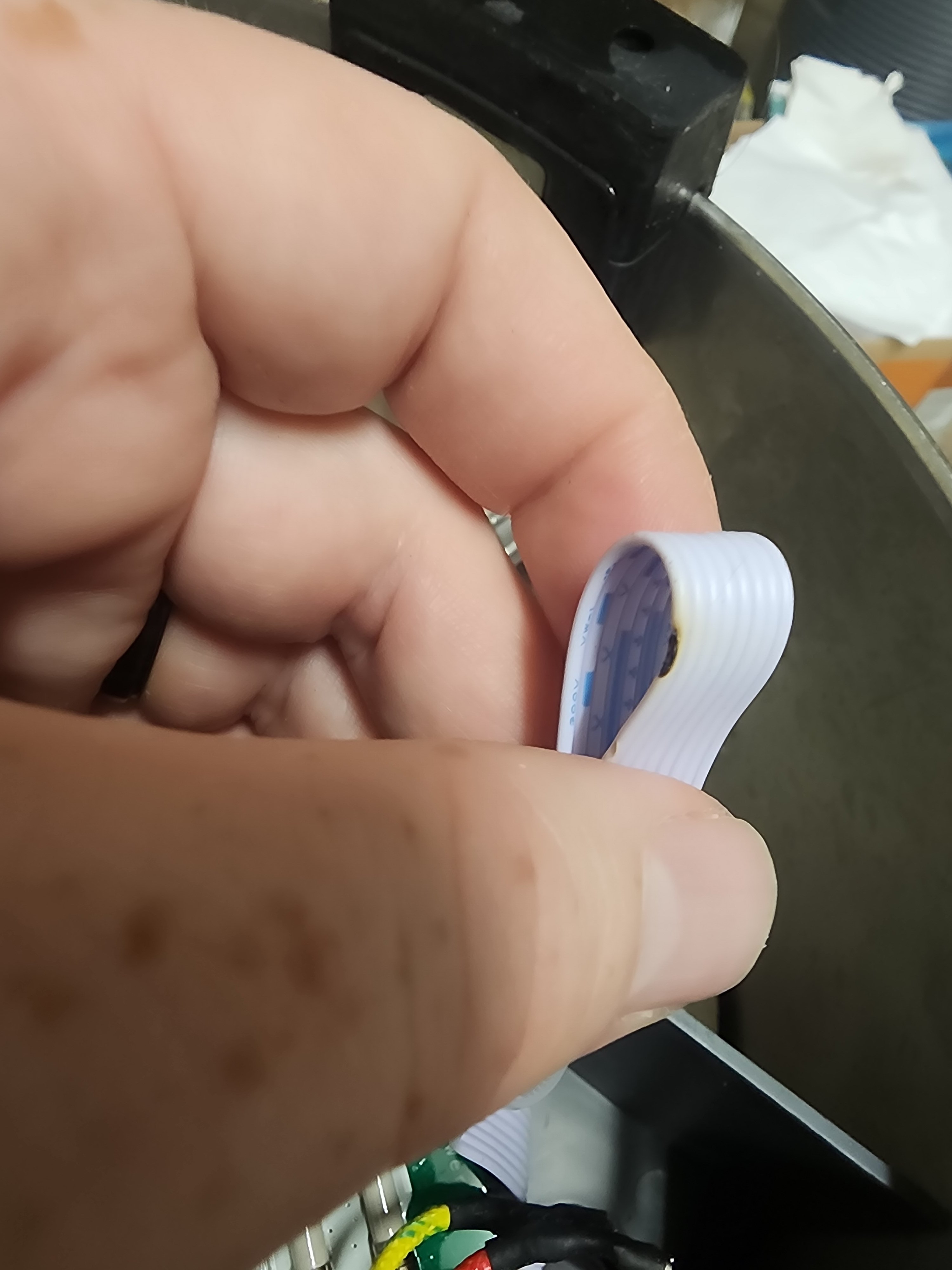

Looks like the communication ribbon cable for the interface got burned a bit too  Not sure if they sell a replacement ribbon cable. For now I'll invest in some liquid electrical tape to seal up that wire and weather proof it

Not sure if they sell a replacement ribbon cable. For now I'll invest in some liquid electrical tape to seal up that wire and weather proof it

Last edited:

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Have a few brews coming up soon so did a spot repair on the ribbon cable. I cut out the bad spot, tinned the wires, soldered it together, then covered with heat shrink to weather proof the repair. I also used cable ties to reduce the stress on the repair as the wire is a quarter inch shorter now and used cable ties to keep the wore away from the power terminals. It wasnt an easy repair as the wores are 24 guage but itll hold. I can see a more permanent power cord repair in the future....This point of failure needs to be taken out of the equation before these units seriously injure someone or their property

Burning like that is an indication of a poor connection. If it's happened to multiple cords, it's most likely the connection on the back of the inlet male receptacle. Second option is poor connection at the inlet: oxidation, wear, etc.

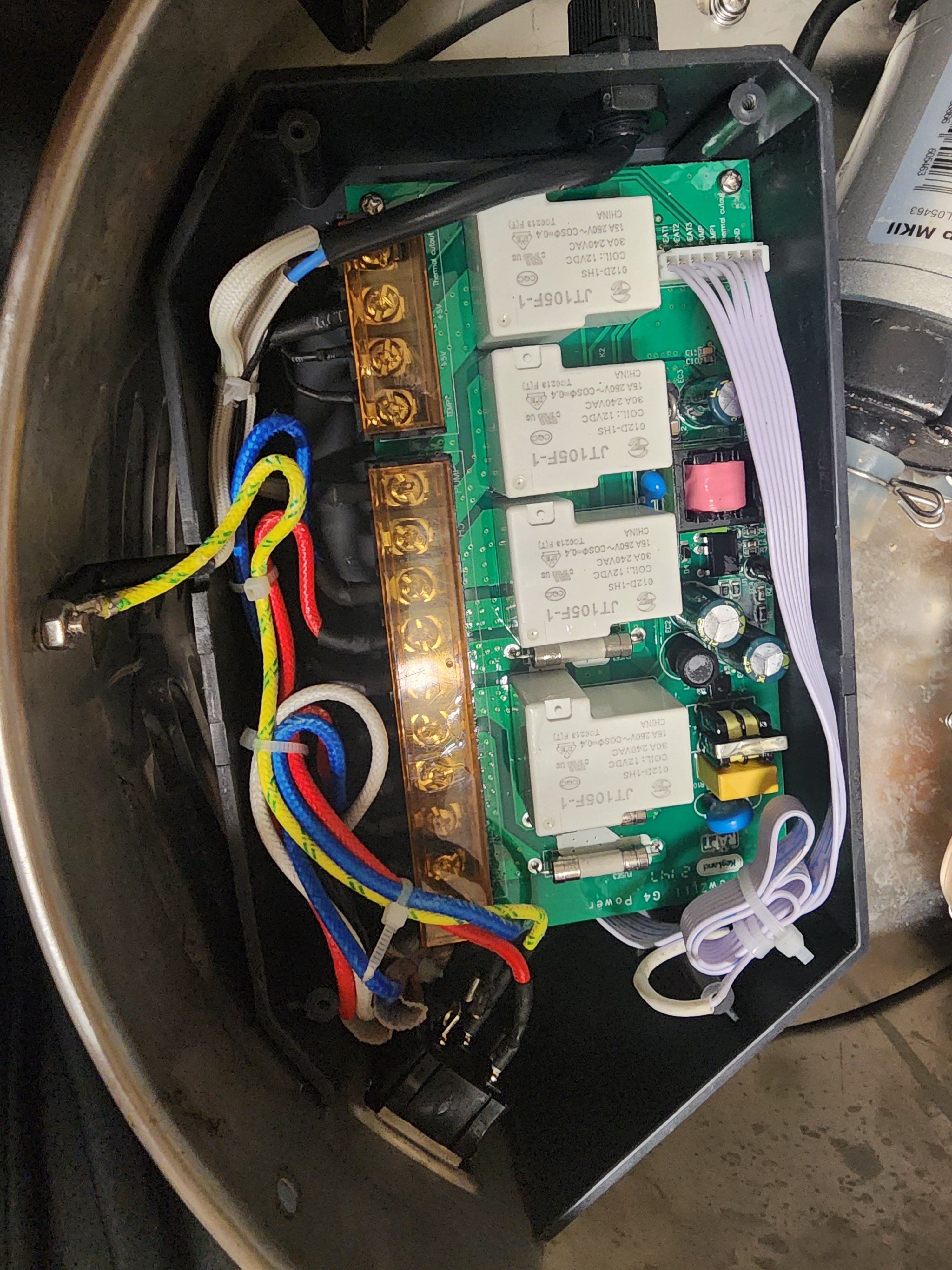

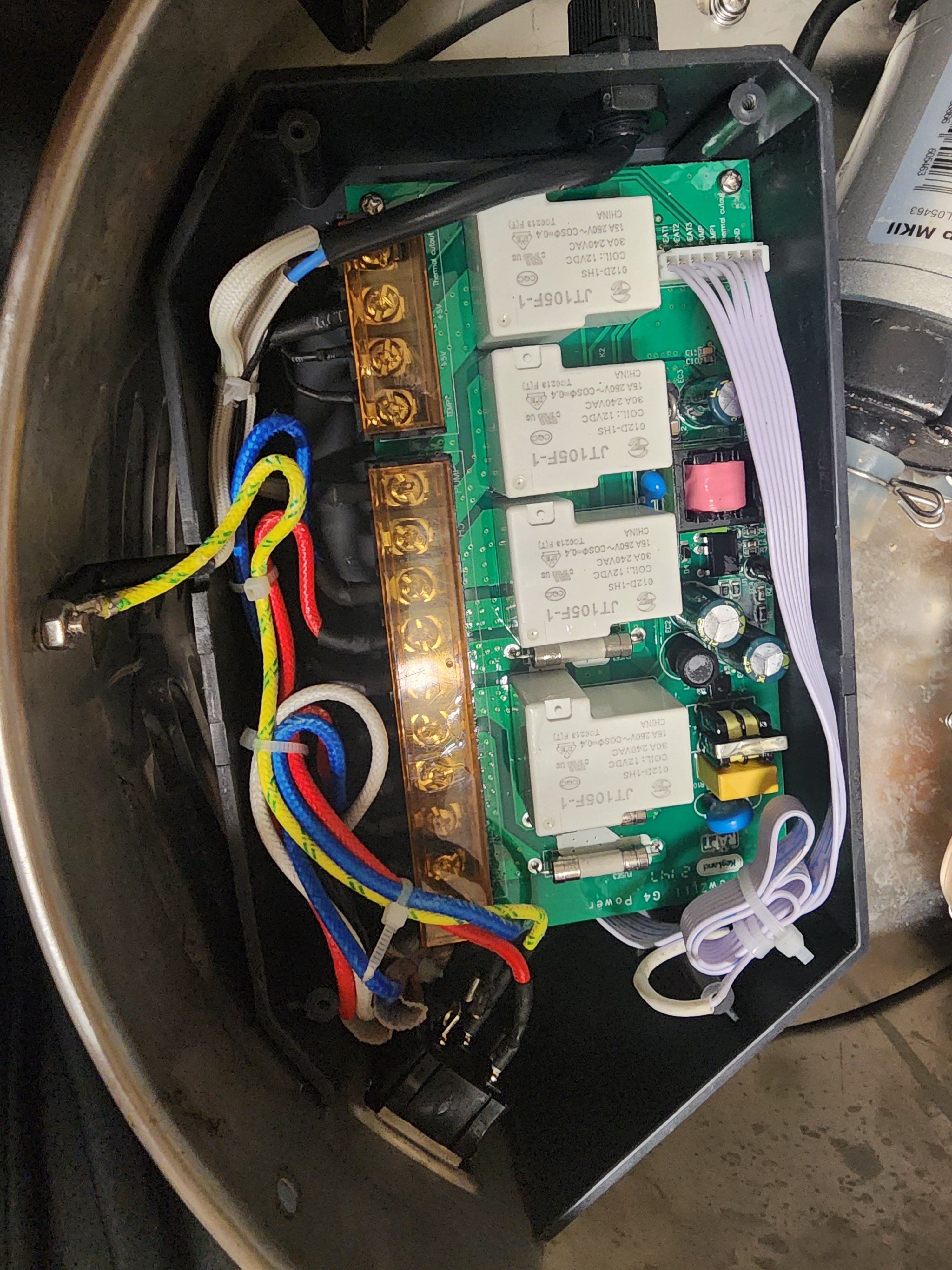

I assume you intentionally unplugged the yellow wire? edit: yellow is ground. Is blue unplugged? Hard to see.

IMO I'd replace the IEC male and reterminate wires with new connectors. (After checking warranty - this is what's called a latent defect.)

I assume you intentionally unplugged the yellow wire? edit: yellow is ground. Is blue unplugged? Hard to see.

IMO I'd replace the IEC male and reterminate wires with new connectors. (After checking warranty - this is what's called a latent defect.)

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

I've Replaced the cord and the recepticle already. I'm now on my third set once the new 15 amp cord comes in from amazonBurning like that is an indication of a poor connection. If it's happened to multiple cords, it's most likely the connection on the back of the inlet male receptacle. Second option is poor connection at the inlet: oxidation, wear, etc.

I assume you intentionally unplugged the yellow wire? edit: yellow is ground. Is blue unplugged? Hard to see.

IMO I'd replace the IEC male and reterminate wires with new connectors. (After checking warranty - this is what's called a latent defect.)

Bad termination on that spade connector, then? A low impedance connector does not melt itself

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Normally I would agree. However I called the kegland Australia number last night, early their time, and they said they were aware of this issue as well. Said they've run onto this in their shop also. They run into it when the unit is moved during use. My unit is stationary.Bad termination on that spade connector, then? A low impedance connector does not melt itself

With that said this could be a very easy fix on the next gen. All they would need to do is get a 6 foot 110 volt pool pump power cord (something like this)

SPX1250WA Pool Pump Power Cord(6-feet Cord Length, 3 Prong Power Cord Type,14 AWG) Cord Set Replacement Compatible with Select Hayward Pump Series Models https://a.co/d/d7rLVJp

, change the terminals on the cord, screw the terminals directly to the board, run the cord through a single hole (with a knot for pressure relief), in the unit using something like this

Joinfworld 72pcs Cable Glands Kit Waterproof Strain Relief Cord Connector Grip Weatherproof Cable Pass Through PG7 1/4" 1/2" 3/4" 1" NPT Wire Grommet https://a.co/d/h6MJCw1

This would accomplish securing the power cord so it doesn't melt and provide strain relief/weather proofing to keep any liquid from getting into the power cord socket.

At the end of the day I really love the gen 4 even with its quirks. There's definitely some room for safety improvement for a gen 4.1 or gen 5.

Last edited:

There's nothing wrong with IEC C connectors or the whole world would be on fire. Something in your unit wiring is high impedance and the molded plastic must be the lowest melt/smoke point.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

There's nothing wrong with those connectors in computers, tv's, and various other electronics they are located in. As being an over 20 plus year IT vet I am very well aware of the connector and their environment use. I have been around these connectors both inside and non climate controlled environments. It's not the connector. It's the connector in an environment where wort is draining, can spew out of the side, and get inside the connector that has caused this issue. The fix would be to weatherproof/Waterproof the connection.There's nothing wrong with IEC C connectors or the whole world would be on fire. Something in your unit wiring is high impedance and the molded plastic must be the lowest melt/smoke point.

Water/moisture can cause high impedance which is the root cause here. Fix the issue with moisture infiltration and that resolves the issue with the melting terminal

Well, personally, I'd consider a non-modular cord a downgrade.

The IEC connectors and twist-lock NEMA are pretty much universal (see Grainfather, Anvil, Sling Blade, etc*). They're not wet rated, but they're not going to let a small spill in. Maybe that the way you're using it is more wet than is typical? Or pins are getting dirty in storage? (Is that pitting on the pin?)

*Clawhammer BIAB system actually has a cool modular waterproof TC plug enclosure. So if you really need a fully waterproof setup, that's an option. I bet BrewHardware could set up something similar. But obviously you could make your own Gen 4 non-modular with that compression fitting and call it a day.

The IEC connectors and twist-lock NEMA are pretty much universal (see Grainfather, Anvil, Sling Blade, etc*). They're not wet rated, but they're not going to let a small spill in. Maybe that the way you're using it is more wet than is typical? Or pins are getting dirty in storage? (Is that pitting on the pin?)

*Clawhammer BIAB system actually has a cool modular waterproof TC plug enclosure. So if you really need a fully waterproof setup, that's an option. I bet BrewHardware could set up something similar. But obviously you could make your own Gen 4 non-modular with that compression fitting and call it a day.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

You know maybe you're right there! I may look into make shifting a plastic cover over the the plug to help keep water out. Either way apologies if I came off a tad snarky in the previous response and I do appreciate the insight! I'm just more so frustrated at the issue and am trying to figure out how I can fix it lolWell, personally, I'd consider a non-modular cord a downgrade.

The IEC connectors and twist-lock NEMA are pretty much universal (see Grainfather, Anvil, Sling Blade, etc*). They're not wet rated, but they're not going to let a small spill in. Maybe that the way you're using it is more wet than is typical? Or pins are getting dirty in storage? (Is that pitting on the pin?)

*Clawhammer BIAB system actually has a cool modular waterproof TC plug enclosure. So if you really need a fully waterproof setup, that's an option. I bet BrewHardware could set up something similar. But obviously you could make your own Gen 4 non-modular with that compression fitting and call it a day.

Oh, I know! Life is always goving us new projects to bang out heads on!You know maybe you're right there! I may look into make shifting a plastic cover over the the plug to help keep water out. Either way apologies if I came off a tad snarky in the previous response and I do appreciate the insight! I'm just more so frustrated at the issue and am trying to figure out how I can fix it lol

I didn't know about the clawhammer setup - if I ever make my dream setup, I'm going to keep that in mind. (I bet it adds 3-5% to the BOM, though!)

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Following up here. It appears Kegland is limited on what parts they can provide to direct consumers here in the US which is understandable. I was referred to reach out to the vendor which is Morebeer. After speaking with both Kegland and Morebeer this is definitely a known issue, but, not a very common issue. It is something that has been seen in less than 1% of the units. Anywho Morebeer has graciously offered to replace the unit and is in the process of sending out a replacement. I would've been happy with a new ribbon (even paying for the part and shipping on my own dime) cable from an RMA'd unit since this unit is out of warranty. I cannot say enough good things about Morebeer customer service on this! I will be brewing a step mashed Festbier next weekend and will be putting the new unit through it's paces for sure

Does the Gen 4 have a warranty in the USA? I was under the impression it didn't. That said, I haven't needed one and since I've now had it for over a year it would be moot anyway; just asking.

BTW, I note that the data cable connection to the unit has a gasket and seems to be protected from moisture intrusion. Since it's located immediately above the power cable connection it seems odd that one connection would be water-resitant and the other not.

Thanks for posting about this. I've made it part of my routine to check that the power cable is firmly seated before powering up.

BTW, I note that the data cable connection to the unit has a gasket and seems to be protected from moisture intrusion. Since it's located immediately above the power cable connection it seems odd that one connection would be water-resitant and the other not.

Thanks for posting about this. I've made it part of my routine to check that the power cable is firmly seated before powering up.

For warranty of our products you have to go back to the distributor. If you are in America this is most likely going to be Morebeer. MoreBeer from our experience have been very good with after sales service and warranty.Does the Gen 4 have a warranty in the USA? I was under the impression it didn't. That said, I haven't needed one and since I've now had it for over a year it would be moot anyway; just asking.

BTW, I note that the data cable connection to the unit has a gasket and seems to be protected from moisture intrusion. Since it's located immediately above the power cable connection it seems odd that one connection would be water-resitant and the other not.

Thanks for posting about this. I've made it part of my routine to check that the power cable is firmly seated before powering up.

There has been some discussions with MoreBeer about possibly selling the American models of the BrewZilla Gen 4 with a hard wired cable and getting rid of the IEC socket all together. It's not quite as convenient but I am not sure that many customers really see the detachable cable as a massive benefit anyway. It's slightly neater to pack down and store but not a massive difference.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Honestly that would be huge!For warranty of our products you have to go back to the distributor. If you are in America this is most likely going to be Morebeer. MoreBeer from our experience have been very good with after sales service and warranty.

There has been some discussions with MoreBeer about possibly selling the American models of the BrewZilla Gen 4 with a hard wired cable and getting rid of the IEC socket all together. It's not quite as convenient but I am not sure that many customers really see the detachable cable as a massive benefit anyway. It's slightly neater to pack down and store but not a massive difference.

And another burnt cord. I've been unplugging from the wall first to prevent shorting. I'll go ahead and replace the plug and cord again but man this is crazy. Any ideas @KegLand ? This 2 and a half year old unit shouldnt be burning through cords like this. Theres another issue with a burned cord earlier in this thread. If there's any ideas, or tips, on how to prevent this from continuing to happen please let me know. Maybe I should look at hard wiring the cord to the board since it seems like the plug is a point of failure?

Heres the link to my previous failure

https://www.homebrewtalk.com/threads/brewzilla-gen4-discussion-tips-talk.702436/post-10221917

View attachment 853417

I had an issue with this, but did not have a wet interface that I'm aware of. Kegland said that they see this in some cases when the cord doesn't get fully seated into the brew unit. I couldn't say for sure how careful I was of that before (but I for sure am now!). I went for a slightly longer cord (but not too long such that I'd get more voltage drop and suffer with less heating element power), and went to copper terminals (lower impedance). Here's the cord I ordered off of Amazon:

https://www.amazon.com/gp/product/B07RVDPJ3B/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

I just assembled the new unit that was received from Morebeer. There are some slight differences but mostly for the better. The feet on the boiler diffuser/filter plate are angled in the middle instead of flat like the original unit. This should help in preventing scorching. The boiler/diffuser filter plate is more solid as well. It fits just right, is missing the second key ring on the outer edge, and is not flimsy like the original. The lid clamps are not assembled by default. Meaning the lid clamps on the original had a rubber coating and were there from the start. The lid hooks on the new unit are solid metal without the coating and have to be assembled out of the box. I like this better because it makes dumping the cleaner water and such out of the unit a bit easier. Also it keeps the hooks out of the way when turning the unit over. The sparge arm fits in the cam lock much more solidly as well. The old one had some play on it...Never leaked though.

A minor difference is the screen finish. Instead of being the glossy/slick finish it is more of a matte finish on the buttons. I gave the unit a quick sponge bath with Dawn dish soap to remove any oily residues for peace of mind. It's been washed out really good and is air drying currently. The lid had a bit of an oil on the inside so this fixed it. Hoping to get a Festbier brew in this evening to put it through it's paces with step mashing. Overall this feels like a much better/solid unit than the original so far! I'll report back with the results!

A minor difference is the screen finish. Instead of being the glossy/slick finish it is more of a matte finish on the buttons. I gave the unit a quick sponge bath with Dawn dish soap to remove any oily residues for peace of mind. It's been washed out really good and is air drying currently. The lid had a bit of an oil on the inside so this fixed it. Hoping to get a Festbier brew in this evening to put it through it's paces with step mashing. Overall this feels like a much better/solid unit than the original so far! I'll report back with the results!

For warranty of our products you have to go back to the distributor. If you are in America this is most likely going to be Morebeer. MoreBeer from our experience have been very good with after sales service and warranty.

There has been some discussions with MoreBeer about possibly selling the American models of the BrewZilla Gen 4 with a hard wired cable and getting rid of the IEC socket all together. It's not quite as convenient but I am not sure that many customers really see the detachable cable as a massive benefit anyway. It's slightly neater to pack down and store but not a massive difference.

As a Gen4 220V owner I can agree that there is not much of a reason to have a detachable power cord. I haven't really ever wanted it except MAYBE for packing down, but seems to pack just fine.

My only real gripe regarding the cord is that the cord could be another foot longer because we have our 220V outlet above waist height and can't pull the unit too far from the wall.

Here's the cord I ordered off of Amazon:

https://www.amazon.com/gp/product/B07RVDPJ3B/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

- 【Enhanced audio performance】- Designed to enhance your audio experience, this Hi-End Power cable ensures a stable and clean power supply to your audio equipment. By reducing power loss and eliminating noise, it helps to improve the overall sound quality, allowing you to enjoy your music in a more immersive and satisfying way.

Yes, I read "reduced power loss" as "low electrical resistance". And since lower resistance = lower temperature, I figured this might give me some robustness to unplanned partially seated plugs. Obviously to a degree...

On the detachable design, I recall reading Kegland's comment that they went detachable because that was a wish they had from Gen3 owners. Now here they are.

It's almost like they need something like a detachable cord that also comes with a hold down bracket you can either screw in or not, based on your preference.

On the detachable design, I recall reading Kegland's comment that they went detachable because that was a wish they had from Gen3 owners. Now here they are.

It's almost like they need something like a detachable cord that also comes with a hold down bracket you can either screw in or not, based on your preference.

I completely understand that wish.On the detachable design, I recall reading Kegland's comment that they went detachable because that was a wish they had from Gen3 owners. Now here they are.

It's really awkward cleaning, moving, or storing equipment with an attached power cord swinging around. I appreciate detachable power cords on all kinds of equipment that needs much handling. Examples: stage sound equipment, location lighting, brew kettles, etc. Even an attached pigtail power cord can be cumbersome at times.

Pan_Kotsky

Well-Known Member

- Joined

- Jan 21, 2017

- Messages

- 60

- Reaction score

- 10

It's been about a year since I got my BZ gen4 35L 220V and I think I mastered working with it to the point that I am ready to push it to the next level.

But before I do, here are my two cents on the yhe common issues. I was able to solve the stuck mash issue using grain conditioning technique. Basically I spray and mix in 2% of water by grain mass. My last Bavarian Wheat went smoothly with no hulls or vigorous mixing. Recirculation valve was 1/2 open most of the time. I do 3 step mash with 40min protein rest 40 min Beta and 20 min alpha + 20 min mash out and cold sparging. The last batch was so smooth, so I was done in under 6 hours from grain in a sack to brewery cleaned and drying on the rack. It is also worth mentioning that I use my good old chinesium corona-style mill to crush my grains. I have it in a custom made plywood enclosure, so can go full blast on my drill. 5kg of grain goes in about 45-60 seconds

So here is the list of upgrades it will be getting in the coming couple of weeks:

1) 14in hop spider

2) HED

3) Two extension rings + 1 recirculation arm extension.

4) RAPT Bluetooth thermometer.

The idea here is to be able to do relatively heavy double mashes. The recepie I am going to do is 42L batch of Irish Red with less then 4:1 water to grain ratio. The grain bill is 11.325kg, which will push the standard malt pipe to the capacity. Wish me luck

But before I do, here are my two cents on the yhe common issues. I was able to solve the stuck mash issue using grain conditioning technique. Basically I spray and mix in 2% of water by grain mass. My last Bavarian Wheat went smoothly with no hulls or vigorous mixing. Recirculation valve was 1/2 open most of the time. I do 3 step mash with 40min protein rest 40 min Beta and 20 min alpha + 20 min mash out and cold sparging. The last batch was so smooth, so I was done in under 6 hours from grain in a sack to brewery cleaned and drying on the rack. It is also worth mentioning that I use my good old chinesium corona-style mill to crush my grains. I have it in a custom made plywood enclosure, so can go full blast on my drill. 5kg of grain goes in about 45-60 seconds

So here is the list of upgrades it will be getting in the coming couple of weeks:

1) 14in hop spider

2) HED

3) Two extension rings + 1 recirculation arm extension.

4) RAPT Bluetooth thermometer.

The idea here is to be able to do relatively heavy double mashes. The recepie I am going to do is 42L batch of Irish Red with less then 4:1 water to grain ratio. The grain bill is 11.325kg, which will push the standard malt pipe to the capacity. Wish me luck

Last edited:

You might wanna try the whirlpool arm and just toss in the hops. I migrated from a hop spider to getting an HED and whirlpool arm and was pleased with the improvement. (Less hops / more flavor)It's been about a year since I got my BZ gen4 35L 220V and I think I mastered working with it to the point that I am ready to push it to the next level.

But before I do, here are my two cents on the yhe common issues. I was able to solve the stuck mash issue using grain conditioning technique. Basically I spray and mix in 2% of water by grain mass. My last Bavarian Wheat went smoothly with no hulls or vigorous mixing. Recirculation valve was 1/2 open most of the time. I do 3 step mash with 40min protein rest 40 min Beta and 20 min alpha + 20 min mash out and cold sparging. The last batch was so smooth, so I was done in under 6 hours from grain in a sack to brewery cleaned and drying on the rack. It is also worth mentioning that I use my good old chinesium corona-style mill to crush my grains. I have it in a custom made plywood enclosure, so can go full blast on my drill. 5kg of grain goes in about 45-60 seconds

So here is the list of upgrades it will be getting in the coming couple of weeks:

1) 14in hop spider

2) HED

3) Two extension rings + 1 recirculation arm extension.

4) RAPT Bluetooth thermometer.

The idea here is to be able to do relatively heavy double mashes. The recepie I am going to do is 42L batch of Irish Red with less then 4:1 water to grain ratio. The grain bill is 11.325kg, which will push the standard malt pipe to the capacity. Wish me luck

Pan_Kotsky

Well-Known Member

- Joined

- Jan 21, 2017

- Messages

- 60

- Reaction score

- 10

Well, I am a bit hesitant about the whirlpool arm due to unorthodox brewing methods I use. First, I am boiling with the lid on and drop in my immersion chiller about 15 mins before the end. I have a giant 50' stainless steel chiller that would be in the way of the arm. In addition, I am afraid the arm won't fit with two 12l extensions.You might wanna try the whirlpool arm and just toss in the hops. I migrated from a hop spider to getting an HED and whirlpool arm and was pleased with the improvement. (Less hops / more flavor)

Good points and valid concerns. I use an IC in the kettle with the whirlpool and I wondered if it would work as well. It worked fine. Phew.Well, I am a bit hesitant about the whirlpool arm due to unorthodox brewing methods I use. First, I am boiling with the lid on and drop in my immersion chiller about 15 mins before the end. I have a giant 50' stainless steel chiller that would be in the way of the arm. In addition, I am afraid the arm won't fit with two 12l extensions.

The whirlpool arm could easily be modified to extend down an extra few inches if needed but I think it would be pretty easy to make a whirlpool arm that fits the collar.

Pan_Kotsky

Well-Known Member

- Joined

- Jan 21, 2017

- Messages

- 60

- Reaction score

- 10

Well, I guess it will be the next upgrade as I've already spent all my beer moneyThe whirlpool arm could easily be modified to extend down an extra few inches if needed but I think it would be pretty easy to make a whirlpool arm that fits the collar

theredviper

Well-Known Member

- Joined

- Jul 1, 2020

- Messages

- 52

- Reaction score

- 23

Just had a similar meltdown on my Gen4 last night. It's my 70th brew on it and no complaints but I have noticed the plug getting hot from time to time (on max boil of course). However last night was something else as I could definitely smell something burning. The brew completed fine but I feared the worst.

I took off the panel below and no damage to the circuit board, just a little on the heat shrink around the connectors as the other user saw above. I suspect some spilled wort (nobody's perfect!) may have been the root cause that got worse over time. I brew exclusively indoors.

However the cord was either melted or otherwise stuck in the socket so I had to get the whole thing out and will replace both.

I guess my question is like the others: any way to prevent this in the future? If somebody hardwires a solution I'd love to see the results. In the meantime I have ordered replacement parts. At least they are generic and relatively cheap.

I don't detach the cord after every use just because I don't want the wear out or loosen the contact from usage.

I took off the panel below and no damage to the circuit board, just a little on the heat shrink around the connectors as the other user saw above. I suspect some spilled wort (nobody's perfect!) may have been the root cause that got worse over time. I brew exclusively indoors.

However the cord was either melted or otherwise stuck in the socket so I had to get the whole thing out and will replace both.

I guess my question is like the others: any way to prevent this in the future? If somebody hardwires a solution I'd love to see the results. In the meantime I have ordered replacement parts. At least they are generic and relatively cheap.

I don't detach the cord after every use just because I don't want the wear out or loosen the contact from usage.

Attachments

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

That was me! Kegland recommended I contact my vendor (morebeer) and they sent a replacement even out of warranty. May want to reach out to your vendor for a replacement.Just had a similar meltdown on my Gen4 last night. It's my 70th brew on it and no complaints but I have noticed the plug getting hot from time to time (on max boil of course). However last night was something else as I could definitely smell something burning. The brew completed fine but I feared the worst.

I took off the panel below and no damage to the circuit board, just a little on the heat shrink around the connectors as the other user saw above. I suspect some spilled wort (nobody's perfect!) may have been the root cause that got worse over time. I brew exclusively indoors.

However the cord was either melted or otherwise stuck in the socket so I had to get the whole thing out and will replace both.

I guess my question is like the others: any way to prevent this in the future? If somebody hardwires a solution I'd love to see the results. In the meantime I have ordered replacement parts. At least they are generic and relatively cheap.

I don't detach the cord after every use just because I don't want the wear out or loosen the contact from usage.

theredviper

Well-Known Member

- Joined

- Jul 1, 2020

- Messages

- 52

- Reaction score

- 23

A whole new unit? Feels like overkill and I've already ordered the replacement parts for ~$20. Although I see yours took more damage than mine.That was me! Kegland recommended I contact my vendor (morebeer) and they sent a replacement even out of warranty. May want to reach out to your vendor for a replacement.

theredviper

Well-Known Member

- Joined

- Jul 1, 2020

- Messages

- 52

- Reaction score

- 23

I'm going to sell my BZ gen 4... I transfer to the fermenter through the tap . it clogs every time... What am I doing wrong?

Do you use a hop spider? Rice hulls? Grain crush size?

I transfer with the recirc pump myself, never had a problem.

Redhouse Brewing

Well-Known Member

- Joined

- Apr 20, 2020

- Messages

- 62

- Reaction score

- 41

Does the false bottom fit tightly so there’s no space for trub to get by? I had this problem with my 3.1 and I bought the heavy duty false bottom and now it never clogs.

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

https://www.homebrewtalk.com/thread...ussion-tips-talk.702436/page-34#post-10399679Do you use a hop spider? Rice hulls? Grain crush size?

I transfer with the recirc pump myself, never had a problem.

Similar threads

- Replies

- 6

- Views

- 422

- Replies

- 46

- Views

- 13K

- Replies

- 46

- Views

- 16K