I feel like I should know this, but how do you control batch sparge rates? When I lift the basket and let it drain, it seems like the sparge water drains out too fast to really be effective. Am I doing something wrong? Should I just add the sparge water to the kettle with the basket in, lift and just let drain? I'm kind of confused on how to sparge with this thing.

Yeah. I hear you on the sparge thing. I'm pretty sure that an effective sparge requires a bit more time than a quick run through the grain bed to rinse away enough of the last bit of converted sugars present in the grain to make it worth while. Seems to me like you are more likely just watering down your first runnings (wort in the kettle when you remove the grain basket).

There are those that believe that a particular grain to water ratio will yield better efficiency in mashing...maybe, but I think it is more likely, over the years, just another one of those things that homebrewers picked up from pro brewers. The larger scale brewers are trying to get as much wort out of a mashing vessel as possible. If that's what you are going for (producing as much wort as the kettle can hold for the boil) a sparge is a must.

I have done my own tests with the Mash & Boil. I wanted to see which way was the best for me.

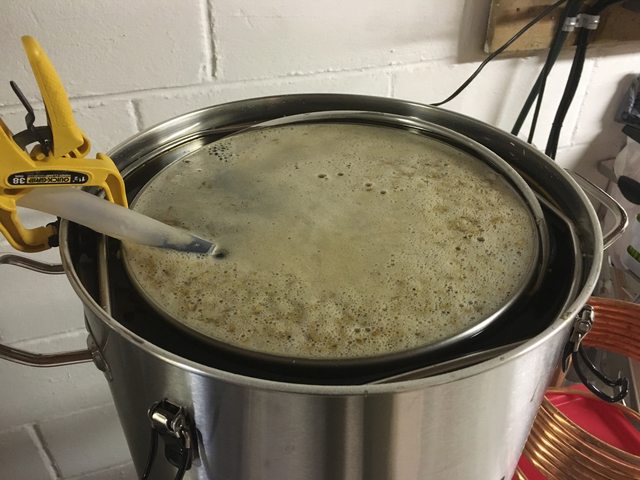

Test 1 - Mash exactly as the instruction manual says to. Remove grains from wort and pour water over the top. 68% effieciency

Test 2 - Mash with the same .3 gal/lb as above, then drain first runnings to a bucket and then add sparge water on top of grains (batch sparge). Stir it up, let it sit for 20 min. and then slowly drain off the second runnings to a bucket. Pull the grains and then return the first and second runnings to the kettle and bring to a boil. IT WAS A TON OF WORK! But I got 76% efficiency. The difference in Test 1 vs. Test 2 is removing the grain from the wort quickly vs. removing the the wort from the grain slowly (with the added benefit of less grain in the kettle at the beginning of the boil).

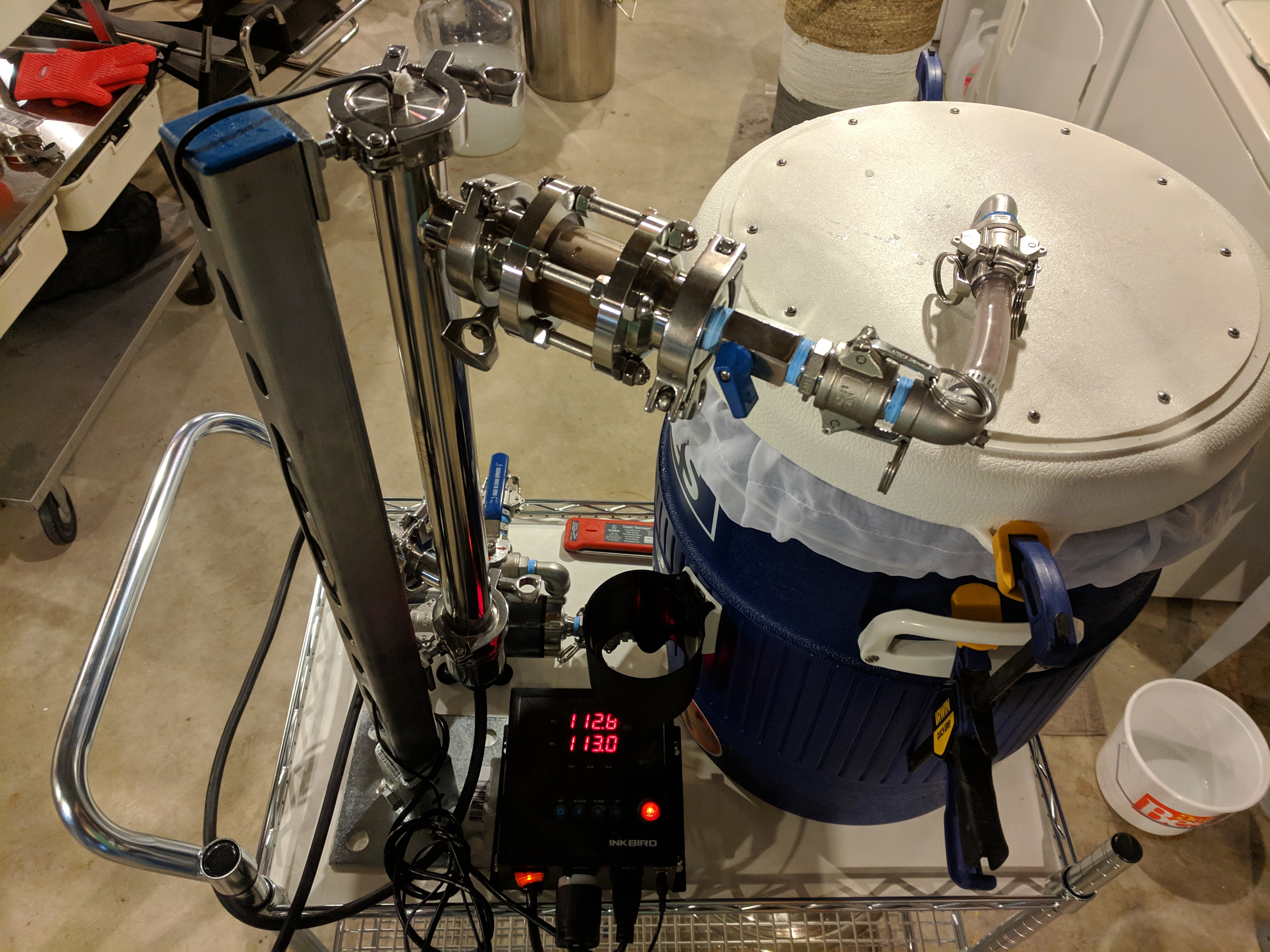

Test 3 - Full volume mash with a "little brown pump" recirculating. No sparge. The simplest & shortest all grain batch I ever made. 81% efficiency.

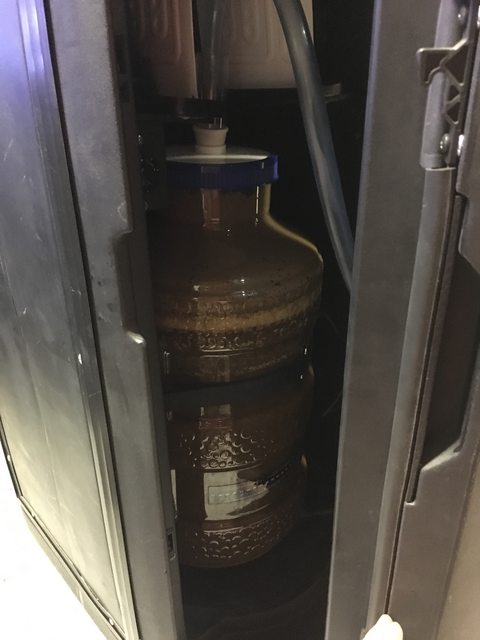

I personally do 4 gallon batches so that I can ferment in corny kegs under pressure (I just believe in my gut that when I do pressure fermentation, I produce cleaner, better tasting beer) and so I am able to do a full volume mash. If you can fit your full volume water into the mash, go for it. If you can recirculate during that mash, you will end up with some pretty great efficiencies. Long time reader of HBT, this is my first time replying. I felt compelled to create an account and reply on this since this is something that I spent a lot of time on trying to figure out for myself with this equipment. Hope it helps.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)