For those who either have built brew rooms or thought about designing a brew room, do you have any recommendations for things you are glad you did and/or things you wish you did?

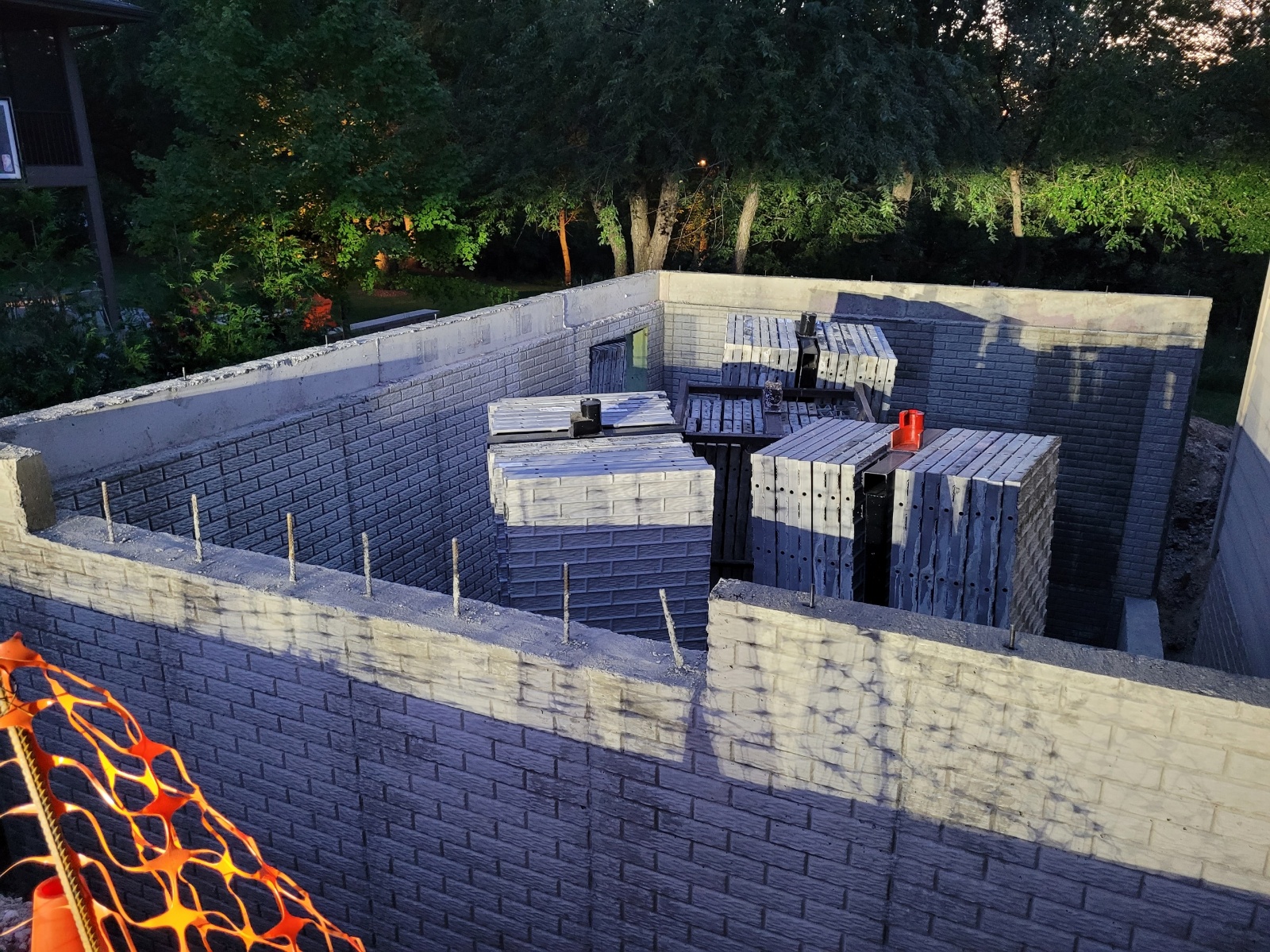

Background: I am building an additional garage for my house and given the way the yard slopes, the builder and I decided rather than fill in the area under the garage, we will make it into a room. The garage floor/brew room ceiling will be engineered and precast in order to hold the weight of a car so hopefully it doesn't come crashing down in the middle of a brew session.

The room will be 16' x 24' with concrete walls and a concrete ceiling. I would say probably half the room will be available for brewing equipment (16' x 12'). The height will be 7'+ (just depends on how it daylights to the existing driveway). It will be wired for electric brewing, probably a 50A panel? We are planning to have an exhaust vent on one wall that can be turned on when brewing. Given the height of the room, a hood doesn't seem feasible. There will be a double door to get equipment in and out and a casement window on the opposite side. There will be plumbing for a sink. I'm planning on a large utility sink with a sprayer/filler faucet for rinsing out kettles and fermenters. The plumbing will be on the 16' wall.

The only thing I can think of that will be fixed in place is the sink.

I was planning on using restaurant-style stainless countertops that could be moved if needed. And rolling stainless shelving for supplies.

Will an exhaust vent be enough to clear out the steam from brewing, or is there something else I should look into? I'm not opposed to a steam condenser setup but that seems like a lot of work and a lot of water.

Is a 50A panel enough? Would 100A be overkill?

Would lower height countertops be better so you can look into the kettle?

Background: I am building an additional garage for my house and given the way the yard slopes, the builder and I decided rather than fill in the area under the garage, we will make it into a room. The garage floor/brew room ceiling will be engineered and precast in order to hold the weight of a car so hopefully it doesn't come crashing down in the middle of a brew session.

The room will be 16' x 24' with concrete walls and a concrete ceiling. I would say probably half the room will be available for brewing equipment (16' x 12'). The height will be 7'+ (just depends on how it daylights to the existing driveway). It will be wired for electric brewing, probably a 50A panel? We are planning to have an exhaust vent on one wall that can be turned on when brewing. Given the height of the room, a hood doesn't seem feasible. There will be a double door to get equipment in and out and a casement window on the opposite side. There will be plumbing for a sink. I'm planning on a large utility sink with a sprayer/filler faucet for rinsing out kettles and fermenters. The plumbing will be on the 16' wall.

The only thing I can think of that will be fixed in place is the sink.

I was planning on using restaurant-style stainless countertops that could be moved if needed. And rolling stainless shelving for supplies.

Will an exhaust vent be enough to clear out the steam from brewing, or is there something else I should look into? I'm not opposed to a steam condenser setup but that seems like a lot of work and a lot of water.

Is a 50A panel enough? Would 100A be overkill?

Would lower height countertops be better so you can look into the kettle?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)