Atlmustang

Well-Known Member

- Joined

- Mar 15, 2016

- Messages

- 229

- Reaction score

- 63

Sharing my brew day yesterday with you all. It was a good day. Falcons/Packers gameday (Rise up!). Georgia Tech won Saturday, UGA lost...it was a great weekend! Beautiful fall weather and what better to supplement the weekend than a brew day? So, I wanted a rye pale ale. Sweetwater had a rye ale they brewed a few years ago they called "Lowryeder" that I loved. The rye gives a buttery body that I love. I was also in the mood for some mosaic hops, so I set out to achieve that.

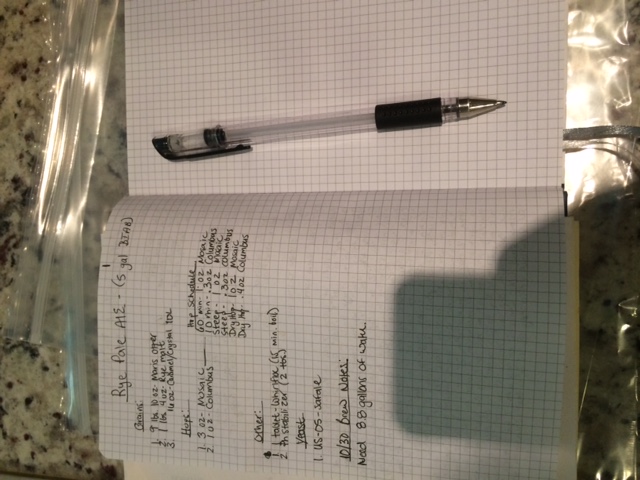

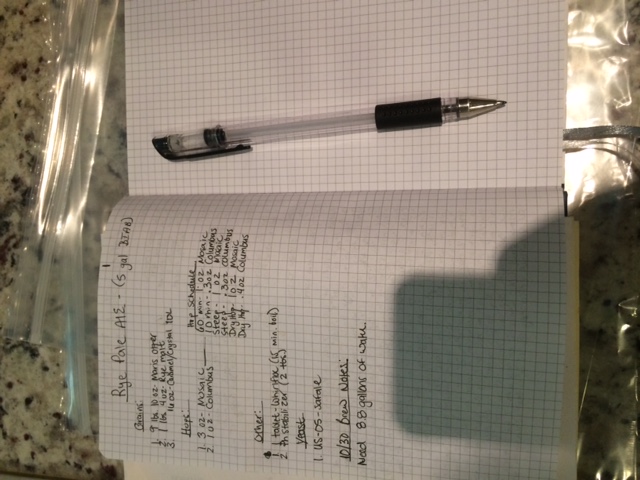

Ingredients: (Hopefully you can read it )

)

Added my 8.8 gallons of water per beersmith scaling to my set up. Going from a 6 gallon batch to a 5 gallon batch. I use my tap water, I just keep a gallon jug around for measuring.

Added my 2 tbs. of Ph stabilizer since using tap water...it hasn't hurt, but I can't say it's helped, so...if it ain't broke don't fix it.

Brought it up to 162F. Perfect! I have 3 burners on this kettle. It's huge. I actually use the front, rear and center burner. Gets it done.

Added my bag and clamps to prepare for grain addition:

Added the grains to the bag and checked the temp after adding grains. Should be a 156F. I go a little higher than 152F to coax additional sugars out using the BIAB method. Perfect again!

Removed the clamps and laid the bag out over the edge of the kettle and set the lid down for mashing for 75 minutes.

Mash completed. Checked final temp of the grains to ensure the pot retained heat above 152F. Kettle did a great job of keeping heat in. Ended at 153.5F.

Removed the grain bag and sat it in a strainer that I sit on top of a pot to lauter for a few minutes. No mash out. I have tried, but I don't think it does anything noticeable for BIAB.

Brought water to a boil. It was a little lazy honestly. I will probably go back out to the garage next time so that I can use my propane burner. The stove has a hard time getting a good rolling boil with that volume and size of the pot. Added additional wort from the lautering process. Did hop additions per my hop schedule above.

Went ahead and got my spoon and thermometer in vat of star san since the cooling process was now in action. Rinsed and wiped down my immersion chiller and threw it in the pot, hooked up my pump and started getting cool water through the chilling system.

Cooled to 75 degrees, siphoned to my sanitized bucket, stirred vigorously to oxygenate and pitched my US-05 Safale. Added sanitized lid and airlock filled with star san water appropriately and closed up brew day!

Will report back in 17 days after 14 days of fermentation/aging and 3 days of keg carbing. OG was 1.050, was calculated to be 1.056, so a little low. But I ended up with 6 gallons rather than 5, probably because of the lazy boil and it didn't boil off as much as the calculator probably assumed. It was really lazy, so I have no doubt that had a hand in ending up with an extra gallon...I'll take it though!

Ingredients: (Hopefully you can read it

Added my 8.8 gallons of water per beersmith scaling to my set up. Going from a 6 gallon batch to a 5 gallon batch. I use my tap water, I just keep a gallon jug around for measuring.

Added my 2 tbs. of Ph stabilizer since using tap water...it hasn't hurt, but I can't say it's helped, so...if it ain't broke don't fix it.

Brought it up to 162F. Perfect! I have 3 burners on this kettle. It's huge. I actually use the front, rear and center burner. Gets it done.

Added my bag and clamps to prepare for grain addition:

Added the grains to the bag and checked the temp after adding grains. Should be a 156F. I go a little higher than 152F to coax additional sugars out using the BIAB method. Perfect again!

Removed the clamps and laid the bag out over the edge of the kettle and set the lid down for mashing for 75 minutes.

Mash completed. Checked final temp of the grains to ensure the pot retained heat above 152F. Kettle did a great job of keeping heat in. Ended at 153.5F.

Removed the grain bag and sat it in a strainer that I sit on top of a pot to lauter for a few minutes. No mash out. I have tried, but I don't think it does anything noticeable for BIAB.

Brought water to a boil. It was a little lazy honestly. I will probably go back out to the garage next time so that I can use my propane burner. The stove has a hard time getting a good rolling boil with that volume and size of the pot. Added additional wort from the lautering process. Did hop additions per my hop schedule above.

Went ahead and got my spoon and thermometer in vat of star san since the cooling process was now in action. Rinsed and wiped down my immersion chiller and threw it in the pot, hooked up my pump and started getting cool water through the chilling system.

Cooled to 75 degrees, siphoned to my sanitized bucket, stirred vigorously to oxygenate and pitched my US-05 Safale. Added sanitized lid and airlock filled with star san water appropriately and closed up brew day!

Will report back in 17 days after 14 days of fermentation/aging and 3 days of keg carbing. OG was 1.050, was calculated to be 1.056, so a little low. But I ended up with 6 gallons rather than 5, probably because of the lazy boil and it didn't boil off as much as the calculator probably assumed. It was really lazy, so I have no doubt that had a hand in ending up with an extra gallon...I'll take it though!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)