I'm anxious to hear your feedback on those Stout Tanks. I've had my eye on those for a while now (no rig is ever complete).

Nice work so far!

TB

Nice work so far!

TB

Which template do you use for visio, Im trying to make a similar type diagram for my setup, I like the non electrical symbols but cant seem to find anything like that. Any chance you could help me out some pointing me in the right direction

You did very well in your testing. I went back over your diagram to see the issue with the element switch. I missed that as well when I reviewed your plan before. Great catch.

P-J

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Just means I want oneVery well done sir :rockin:

https://lh6.googleusercontent.com/-M96tJsr0k9E/UDRh8TWAXxI/AAAAAAAAD0s/AKnWcBxCCzU/s1600/20120819-DSC_2219.jpg[/IMG]

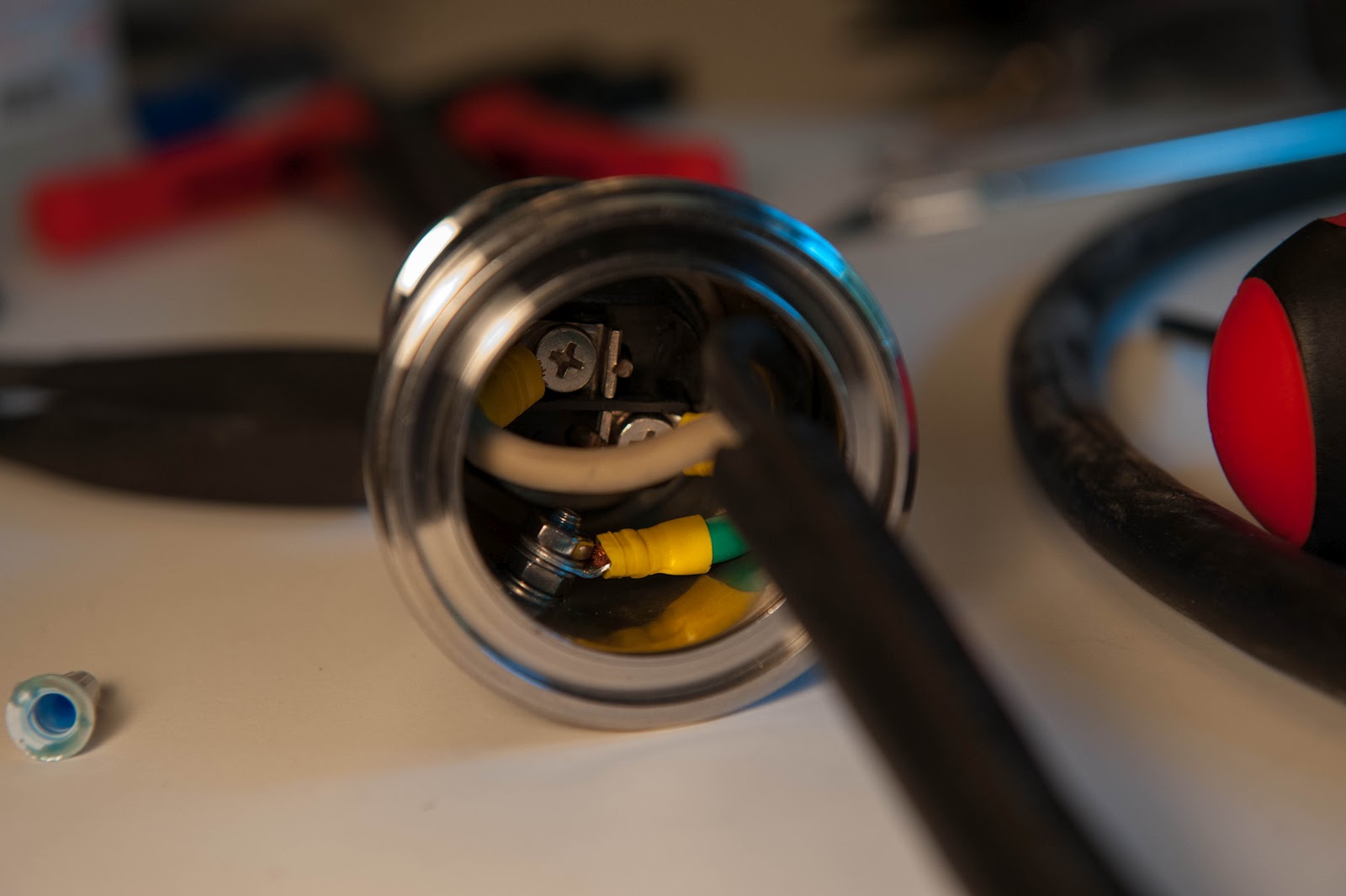

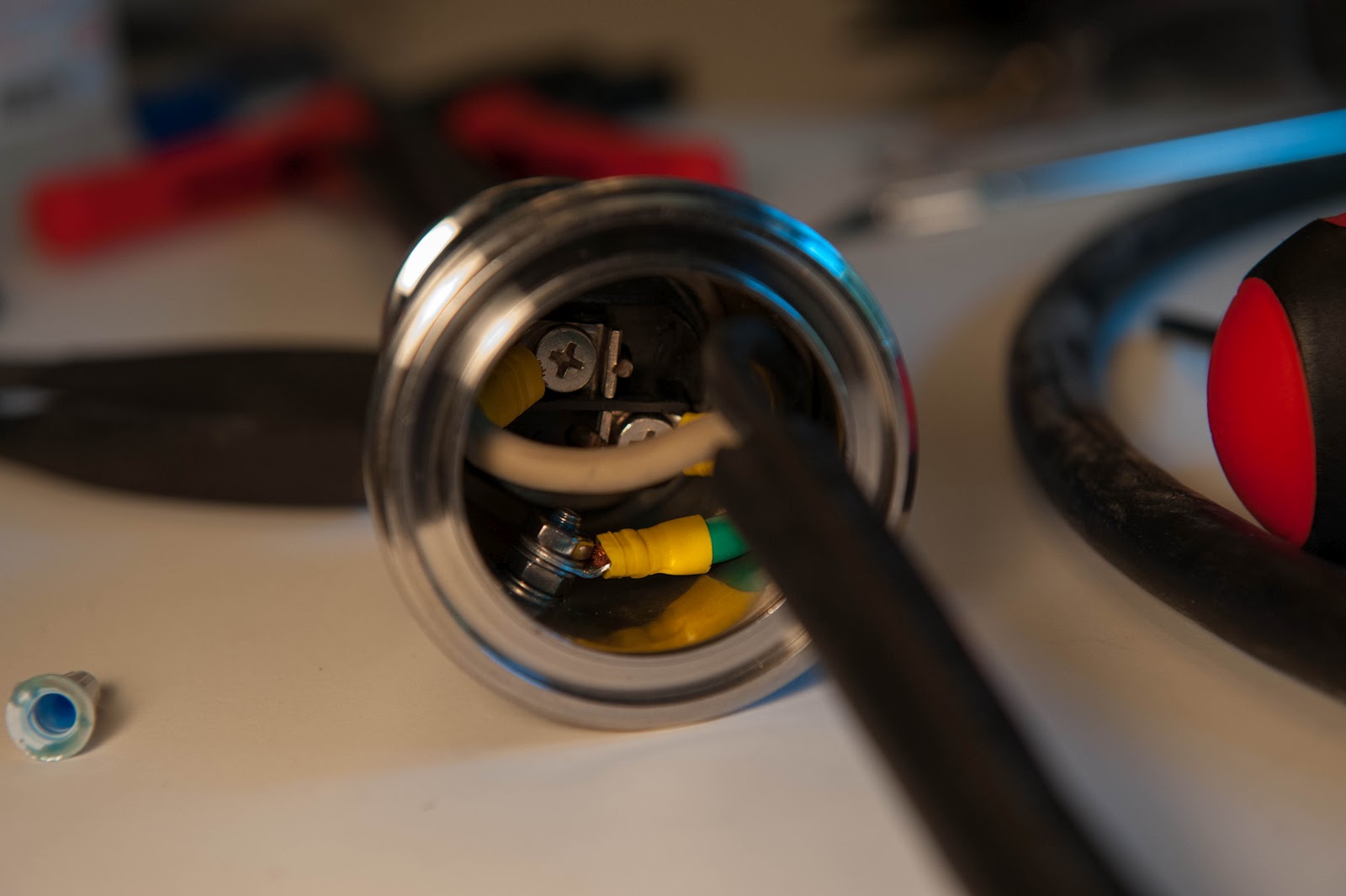

Bolts, could you describe in more detail how you built the heating element housings. Where did you get the tri clamp fittings? I am attempting to build a heatstick similar to Airbalancer's design

https://www.homebrewtalk.com/f51/ultimate-heatstick-240-volt-116049/

but what you have is perfect for what I want. Ive seen a lot of slap happy designs with JB weld and plastic PVC, but the stainless tri clamp is the most solid adaptation I have seen. Thanks. Great build BTW.

I need to see this in person and am local, pm me if I can tempt you with a sixer of your favorite from belmont station.

So you have the 1.5" and the ripple didn't fit? But the standard straight fold back did?

I'm in process of having a 2" ferrule welded to my HLT for this and want to make sure I get the right element. The 2" triclamp element fitting is in the mail.

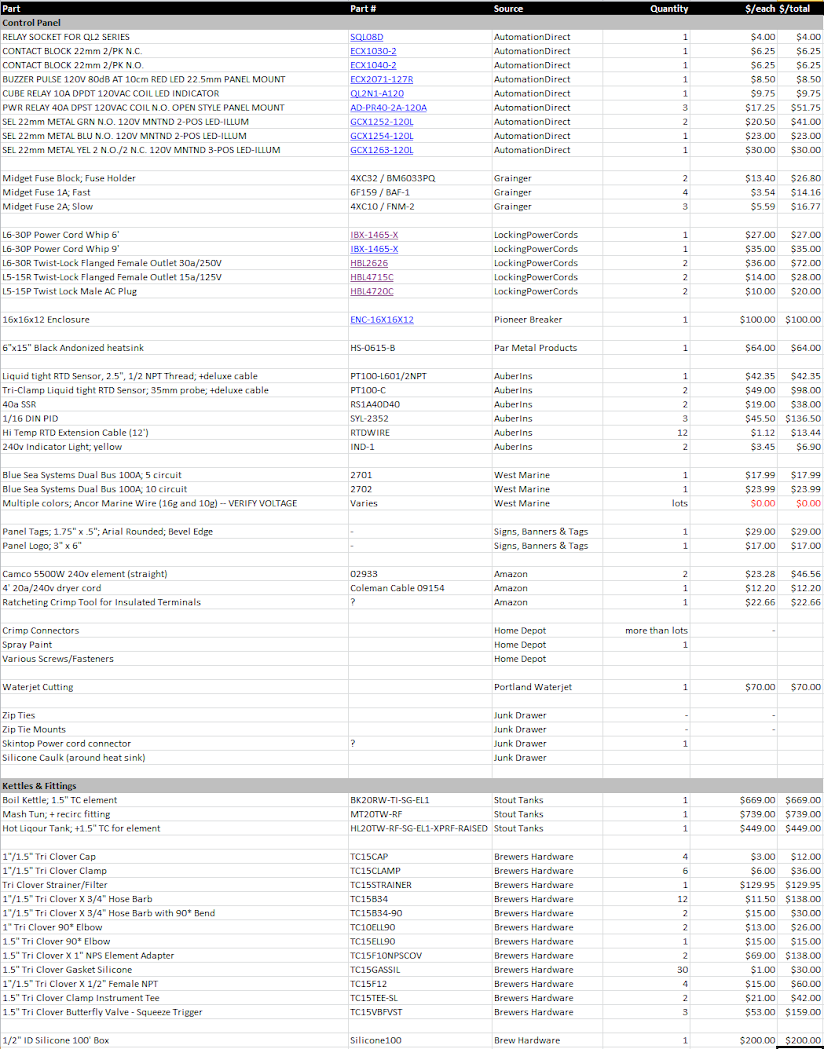

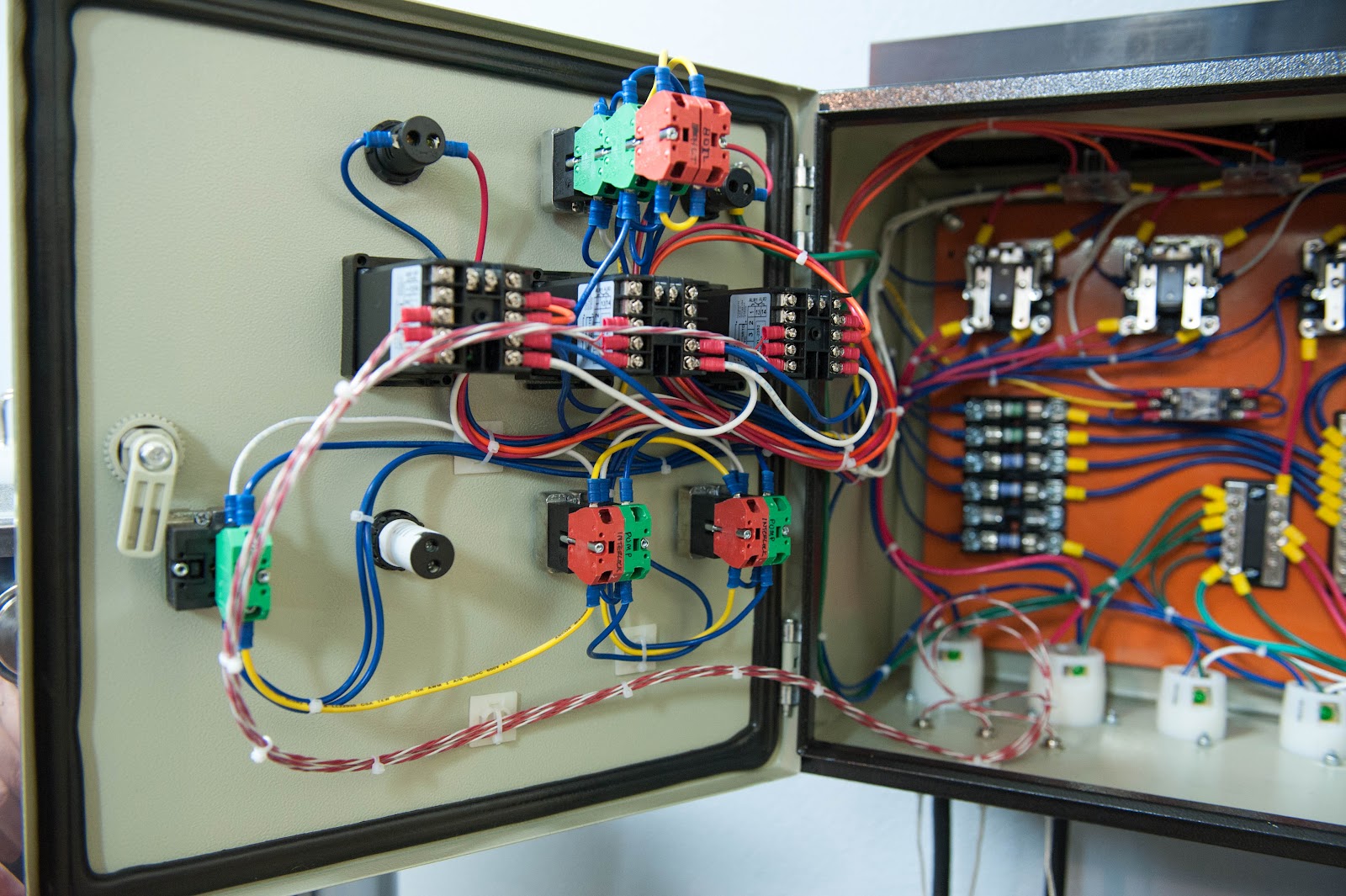

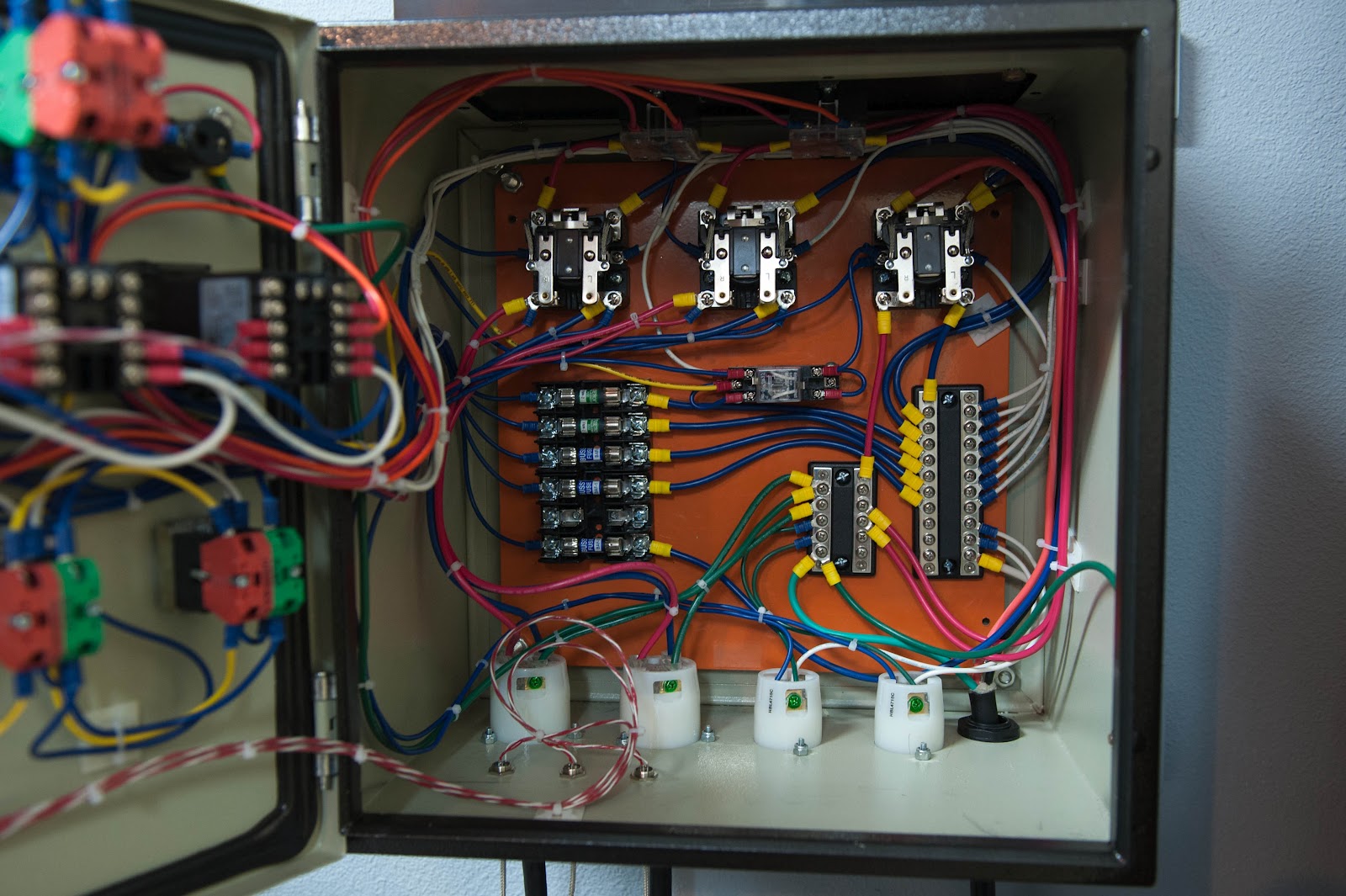

Looks very nice. The wiring is pretty neat and tidy. The lamicoid nameplates really add a professional touch. Is a ground bonding jumper required for the door?

IT'S SO FLUFFY!

HAHA yes. Monsters, Inc. quote. It's a good thing.

Bolt - did you ever wire in the alarm? I don't see it in your latest wiring diagram and none of your progress photos show the alarm wired up.

Thanks by the way, I am basically planning on copying your design for my control panel.

I should have a bill-of-materials and my "what I would do differently" thoughts up this weekend.