Burquebrewer

Well-Known Member

I would say your liquid lines should be 3/8 or 5/16 which are within 1/8 of each other.

As for line length, I'm in the shorter line camp and here is why:

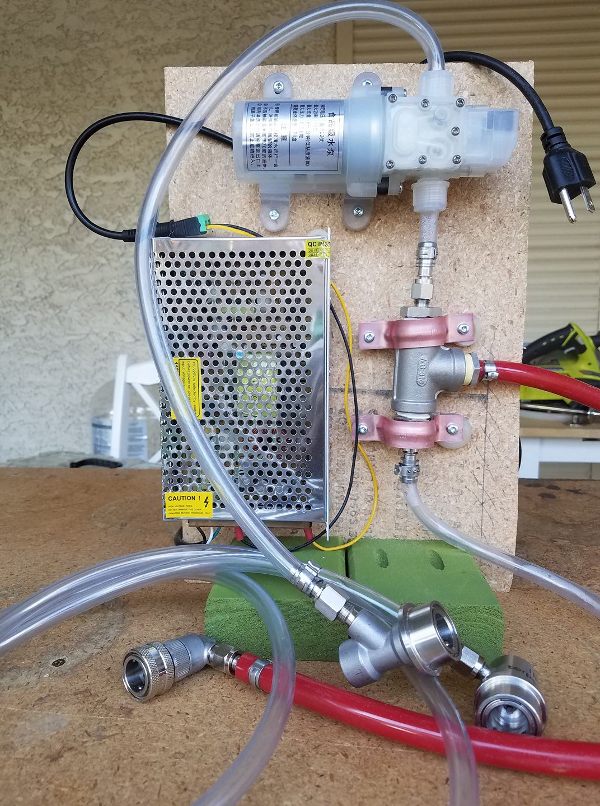

Longer line will allow the liquid to be exposed to the ambient temperature of the room, raising the temp of the fluid which is already having to deal with the temp increase from running through the pump itself. Unless you are going to leave it in a refrigerator during the process. There is also the question of the resistance of tubing on the fluid which is negated by the fact that if using the same type of pump Blichmann is using you can adjust the litters per minute. So there really is no need, like with a kegerator, to calibrate the psi with hose length. The one I built which is pictured above as an adjustment screw which allow a range of 1.8 liters to 4.2 liters per minute.

I used the same pump ElChangoGuero used. I'm not sure if the flow is adjustable. I'm going to use it today for the first time, so I should know soon.

Thanks.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)