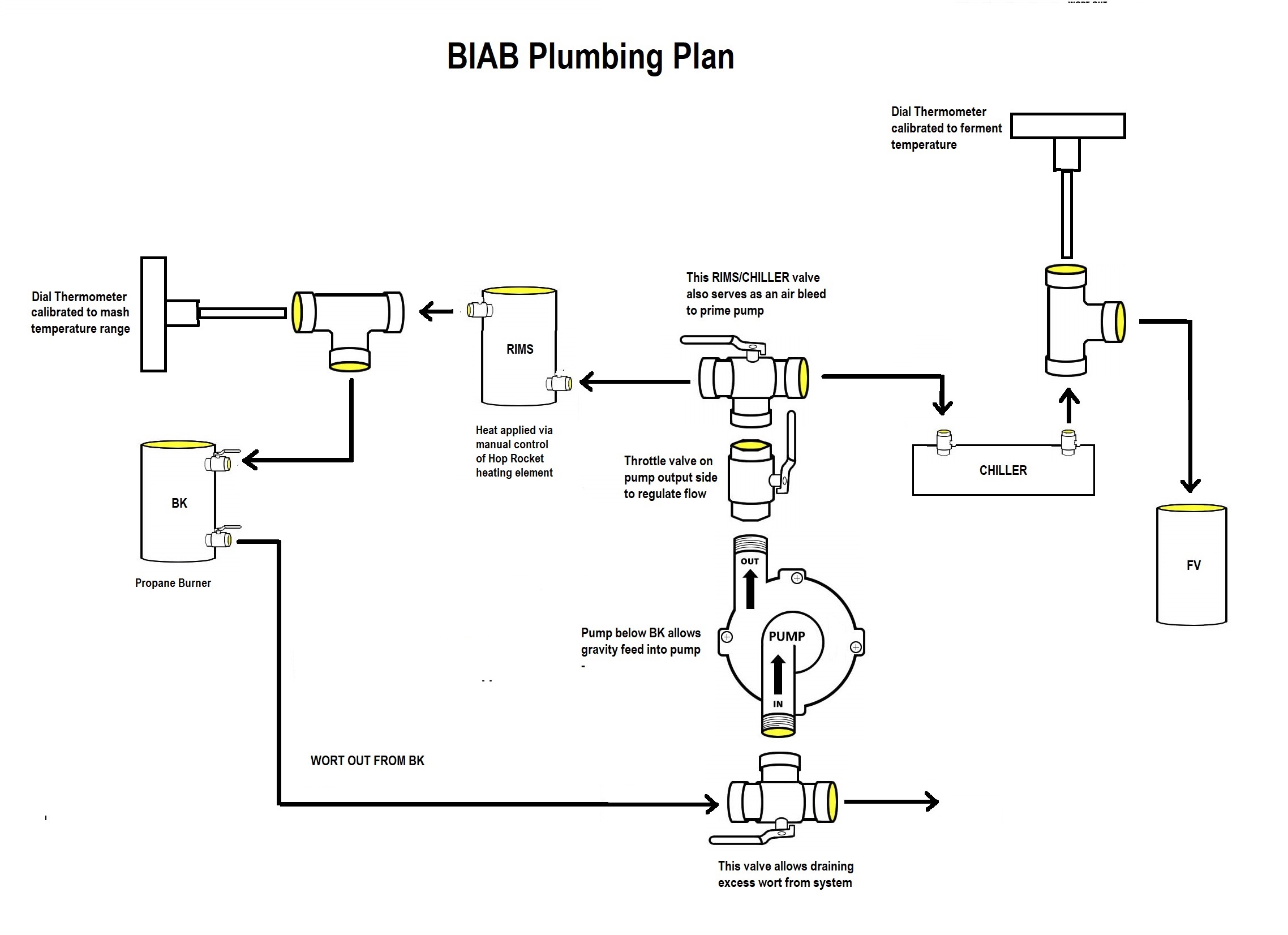

I'm moving to BIAB (basket) and this is my plumbing plan. If you have done this and see any problems with this setup, please advise. Thanks again everyone that replies for your comments and suggestions, I have learned a lot from this forum.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)